Horizontal Bead Mill Sand Mill for paint, pigment nano grinding

Brand :CAREER

Product origin :China

Delivery time :20 days after receiving down payment

Supply capacity :20unit/month

This sand/bead mills are widely adopted in carbon nano tube,LFPO,graphene,papermaking, dye and pigment,paint and coating,ink,nano color paste, nano ceramic,biomaterial etc. new material field.

Product Show

Technical Specifications

| Model | Power | Speed(rpm) | Linear speed | Capacity KG/H | Media filling volume |

| PT-5 | 5.5KW | 2800 | 15 m/s | 100-180 | 10KG |

| PT-15 | 22KW | 2200 | 15 m/s | 150-400 | 30KG |

| PT-30 | 37KW | 1500 | 15 m/s | 200-600 | 60KG |

| PT-60 | 75KW | 1200 | 15 m/s | 500-1000 | 135KG |

| PT-90 | 90KW | 1000 | 15 m/s | 800-1500 | 220KG |

| PT-150 | 110KW | 800 | 15 m/s | 1200-1800 | 336KG |

Features

1) Suitable for material with LOW-MIDDLE viscosity, high solid content and high refining requirements .

2) Compact body design, carbon steel frame, hard alloy with special treatment for contact parts, excellent painting effect.

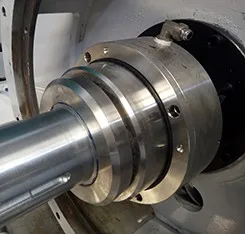

3) Advandecd double end mechanical seal, which ensures the long life of shaft seal and good sealing effect .

4) 4 cooling system:

a)Feeding pipe jacket cooling.

b) High efficiency large area spiral ribbon type jacket water circulation chamber wall cooling.

c) End cover corrugated cooling.

d)Mechanical seal cooling,which ensure the best cooling effect.

5) Dynamic turbine discharge system adopt unique large area tubular reseau separator, precise separation & smooth discharge, solving the problems of slow discharging speed and blocking of grinding medium.

6) The whole grinding barrel and shaft and beads adopt high-strength alloy steel, zirconia, silicon carbide, etc, which ensures the long life and reduce metallic pollution.

Detailed Images

|  |  |

double end mechanical seal | strengthened Alloy structure | cylinder inside |

Nano Laboratory

|  |  |  |

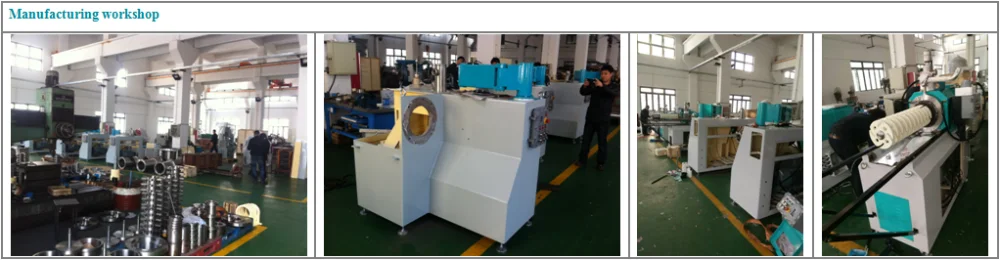

Workshop

|

|

Packaging & Delivery

Lab Experiment Equipments: disperser(1.1kw), lab sand mill, ceramic sand mill, laser granulometer

Experiment Process:

1) Material information

2) Experiment preparation

3) Experiment mode confirm

4) Experiment execute

5) Report Generate

6) Sending test products to clients