- Home

- >

- News

- >

- die casting manufacturing

- >

- 10% steady growth every year: China's die-casting industry is developing rapidly

10% steady growth every year: China's die-casting industry is developing rapidly

Since the advent of pressure casting in the 1940s, the development of precision machining as a metal part close to the final shape has been in the ascendant. New progress has been made in die casting equipment and its control, die casting process and die casting alloys. With the rapid development of China's national economy, all walks of life go hand in hand, and the die-casting industry closely related to it will undergo tremendous changes. The number of professional die-casting factories will increase and the scale will gradually increase, and some will extend its subsequent processing services.

Die-casting enterprises show a trend of merger, joint and attachment; joint ventures, foreign investment, joint ventures, joint stocks and other forms of die-casting enterprises will increase; some die-casting plants will consider joining fleet-based purchasing companies to become suppliers/manufacturers/ A member of an intensive group of contractors. In addition, many component suppliers will also set up their own die casting plants. At the same time, the market needs to mass produce complex thin-walled and beautiful metal parts to meet the increasingly high requirements of die-casting parts in the automotive industry, electronic communication and household appliances, toys and other industries. Die castings are used in a wide range of applications, including a wide range of product areas and industrial categories. In all of these applications, if the number is large, the variety is large, the requirements are strict, the quality is high, and the amount of metal materials is large, it should be the first to push the automotive industry. For a long time, the automobile industry has been the largest market for the die-casting industry. In recent years, the development of China's automobile industry has also spurred the die-casting industry to enter a new development period. The application of die-casting parts in automobiles is advancing with the times. In the market of die-casting parts, the proportion of the automobile industry is extremely large. According to statistics from relevant parties, although the share of the automobile industry is different due to the different industrial structures of different countries, But the above ratio can always be among the best.

I. China's die-casting industry is developing rapidly and has huge growth space.

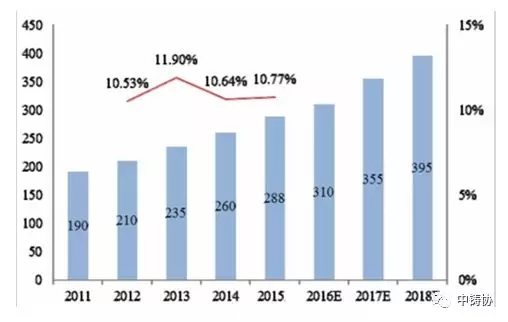

In recent years, China's die-casting industry has maintained a steady growth of more than 10% every year. In 2012, China's die-casting production exceeded 2 million tons. In 2014, China's die-casting production reached 2.6 million tons, up 10.64% year-on-year. Die casting production will exceed 3 million tons, and will achieve 3.95 million tons of die casting production in 2018.

2. China's die-casting industry enterprises, scale

1. China's existing die-casting enterprises and die-casting related enterprises have about 6,000-8,000, of which more than 70% produce die-casting parts; produce die-casting alloys, die-casting machines, molds, melting equipment, testing equipment, peripheral equipment, Die casting consumables, die casting machine parts and other enterprises account for about 30%.

2. At present, there are more than 120 domestic die-casting machine enterprises in China, including more than 30 of them, and the annual production of die-casting machines can reach more than 6,000. The largest die casting machine used in the country is 4,500 tons. Domestic die-casting manufacturers have more than 80,000 die-casting machines of various types, of which die-casting machines imported from abroad account for more than 7% of the total, and are concentrated in some domestic Sino-foreign joint ventures, large state-owned enterprises, newly established large-scale modern enterprises and A powerful private enterprise.

3. At present, there are about 800 die-casting mold enterprises in China with an annual output value of RMB 13 billion. The design and manufacture of domestic die-casting molds can basically meet the needs of most industries such as automobiles, motorcycles, home appliances and light industry. The average price of domestic die-casting molds is about one-half of the average price of foreign advanced enterprises, and the life expectancy is about one-half of that of foreign countries.

4. The output of die castings in China has already ranked first in the world. The gross domestic product has reached 50 trillion yuan. Among various enterprises, large-scale annual production of 10,000 tons of die-casting parts, the largest annual output of 60,000 tons; medium-sized annual output of die-casting parts of about 5,000 tons; small-scale annual output of die-casting parts of 1,000 Tons of smaller-scale annual production of die-casting parts is only a few hundred tons. The proportion of various die-casting parts is about the total amount of die-casting parts, aluminum alloy accounts for about 83%, zinc alloy accounts for about 15%, and magnesium alloy accounts for 2%.

5. The main output of die-casting products is mainly automobile and motorcycle parts. The die-casting parts used in each automobile have more than 40 die-casting parts such as gearbox housing, cylinder block and crankcase, and the average die-casting on each car. 75 kg. The total weight accounts for more than 50% of the total domestic production of die castings.

6. The types of Chinese die-casting products are diversified, including automobiles, motorcycles, telecommunications, home appliances, hardware products, power tools, IT, lighting, escalator steps, and toy lights. With the improvement of technology level and product development capability, the types and application fields of die-casting products have been continuously expanded, and the die-casting equipment, die-casting molds and die-casting processes have undergone tremendous changes. In addition to traditional die-casting parts, automotive structural parts are a bright spot. In addition, the demand for metal parts for smart phones adds power to die-casting.

3. Die casting technology, equipment, management, and talent level have improved significantly

In the research and development of die-casting technology, the deepening of aluminum alloy die-casting will still be a major direction in the development of die-casting technology.

The first is to promote the application of new high-strength, high wear-resistant die-casting alloys, research on color-coded die-casting alloys and new die-casting alloys for castings with special safety requirements;

The second is to develop die-cast aluminum alloy with stable performance and easy control of composition;

The third is to simplify the alloy composition, reduce the alloy grade, and provide the basis for green production;

The fourth is to further improve the new die casting process (vacuum die casting, oxygenation die casting, semi-solid die casting, extrusion casting, etc.);

The fifth is to improve the ability to respond quickly to the market, and promote parallel engineering (CE) and rapid prototyping technology (RPM);

The sixth is to carry out research and development of CAD/CAM/CAE systems; the seventh is to develop and apply more die-cast aluminum alloy parts.

In recent years, with the rapid development of China's automobile, motorcycle, household appliances, electronic communications and other industries, especially the automotive industry, China's die-casting industry has been moving forward at an unprecedented speed. Since China's accession to the WTO, after the market was fully liberalized, the domestic die-casting machine manufacturing industry has been hit, forming a situation of more intense competition in the domestic die-casting machine market. Objectively speaking, the quality performance level of our domestic die-casting machine is quite different from that of foreign advanced industrial countries. However, due to the wide distribution of die-casting parts, from transportation energy to household appliances, the daily-use industry from thousands of households There are all kinds of die castings, and these die castings have different market requirements, which brings space to the domestic die casting machine market, especially medium and small die casting machines. This space may continue for a long time. . This provides an advantageous opportunity to accelerate the improvement of the quality and performance of domestic die casting machines. As the processing base of the basic industry of the world machinery industry, especially the processing base of die-casting parts, China has undoubtedly brought good opportunities to the industry. At the same time, it has also stimulated the improvement of the quality of basic products in China, requiring the quality and performance of mechanical equipment to be synchronized. Progress.

On the equipment, for the large-scale die-casting machine, with the development of China's automobile industry and the increasing demand for large-scale die-casting parts for export, the production quantity of domestic large-scale die-casting machines is difficult to meet the demand, which is the import of large-scale die-casting machines. Created a good opportunity. For a small number of domestic large-scale die-casting machines, there is still a certain advantage in terms of cost performance. Therefore, it is urgent to seek advanced foreign technology and introduce advanced foreign components to accelerate the improvement of the quality and performance of its products. At the same time, the foreign die-casting machine manufacturing industry is looking at the huge potential of the Chinese market. In order to reduce costs, it is becoming more and more obvious and urgent to expand the market and seek cooperation and development. This will give the two sides increased cooperation, learn from each other's strengths, and bring favorable opportunities. This is the mainstream of China's die casting machine production and market.

In addition, domestic die-casting machine manufacturers have mushroomed in recent years, so the domestic die-casting machine faces competition, including imported die-casting machines and die-casting machines manufactured by dozens of domestic companies. Imported die-casting machines are in high quality, high performance and high price, mainly to meet the needs of a small number of customers in the domestic market, and most of the market is still domestically produced die-casting machines. At present, the quality and performance of domestic die-casting machines are relatively large, and the price is high. There is also a high level of disparity, but due to the large market capacity, there is still a certain living space for domestic die-casting machines with poor quality and performance. Therefore, for us, the challenge of accepting imported die-casting machines in the improvement of quality and performance, as well as the challenges of domestic die-casting machines, will face the severe situation of survival of the fittest in a short period of time.

China's die-casting machine production enterprises are mainly distributed in the Yangtze River Delta and Pearl River Delta regions. There are more than 100 production enterprises and more than 10 enterprises above designated size. From the perspective of market competition, China's die-casting machine industry has a low concentration. Although China's die-casting machine industry technology has made great progress, the domestic high-end die-casting machine market is still being recognized by internationally renowned companies such as Swiss Buhler, German Fulai and Japan Ube and Toshiba. Waiting for the company to occupy. Domestic brand die-casting machines still have a certain gap with foreign famous brand die-casting machines in terms of brand, technology, sales network, production management, etc. In recent years, die-casting machine manufacturers represented by Lijin Technology, etc. are constantly introducing and digesting. On the basis of absorbing foreign advanced technology, we have adhered to the development path of independent research and development, production, education and research. Through years of efforts, we have made great breakthroughs in real-time control of injection technology, key performance indicators of die-casting machines, and integration of die-casting islands. The machine manufacturing level is close to foreign famous brands. Combined with the perfect product serialization and cost-effective advantages, the domestic high-end brand die-casting machine has basically replaced the well-known foreign brand die-casting machine to meet the demand for high precision and high reliability in the Chinese die-casting parts market.

Die-casting enterprises improve the production and quality management mode, from the propulsion type of production to the pull-type production mode, to achieve timely, appropriate, and appropriate production, so as to achieve the goal of maximizing profits.

Improving production and quality management models must be considered in all aspects and in all aspects. In the management of production systems, it is necessary to establish a production site quality system, 5s and continuous improvement of system construction, inventory and production planning systems; in the management of die casting, we must pay attention to equipment efficiency, reduce labor costs, and reduce logistics such as broken materials and missing parts. Loss; in improving quality, we must consider reducing defective products and manual repair to prevent problems of quality instability.

In addition, it is necessary to comprehensively promote continuous improvement and achieve a virtuous cycle of production mode. Continuous improvement is the basis for the growth and continuous development of corporate profits, and is also a prerequisite for achieving a virtuous cycle of production. In the future, various technical tools can be used to obtain continuous improvement technology, and it can be applied to die-casting production management to realize the advanced technology, advanced industry and advanced management of die-casting enterprises.

In the increasingly fierce market competition, die-casting production enterprises should dare to promote the transformation of production methods, improve production and quality management models, and establish a quality management system that continuously improves product quality, achieves standardization and visualization, and ultimately realizes the largest profit of enterprises. Chemical.