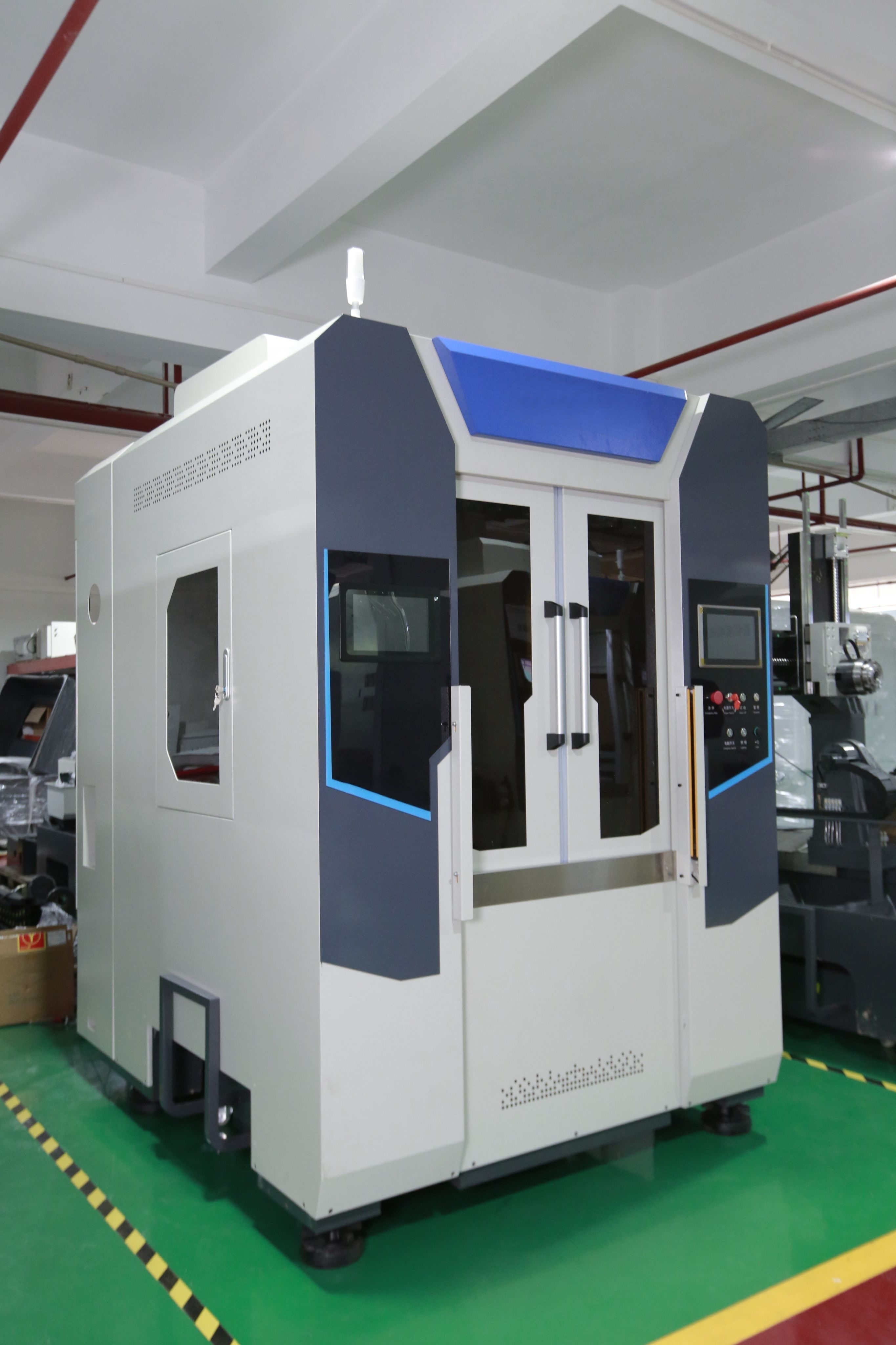

LR-ZM6C-90 Intellectual ability grinding machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

Engineered to meet the challenges of large - scale production, this Large - Format Deburring Equipment offers unrivaled performance for industries where size and reliability are paramount.

In the demanding landscape of industrial manufacturing, the LR - ZM6C - 90 Deburring Machine, a leading Large - Format Deburring Equipment, stands as a testament to power and precision for oversized workpieces.

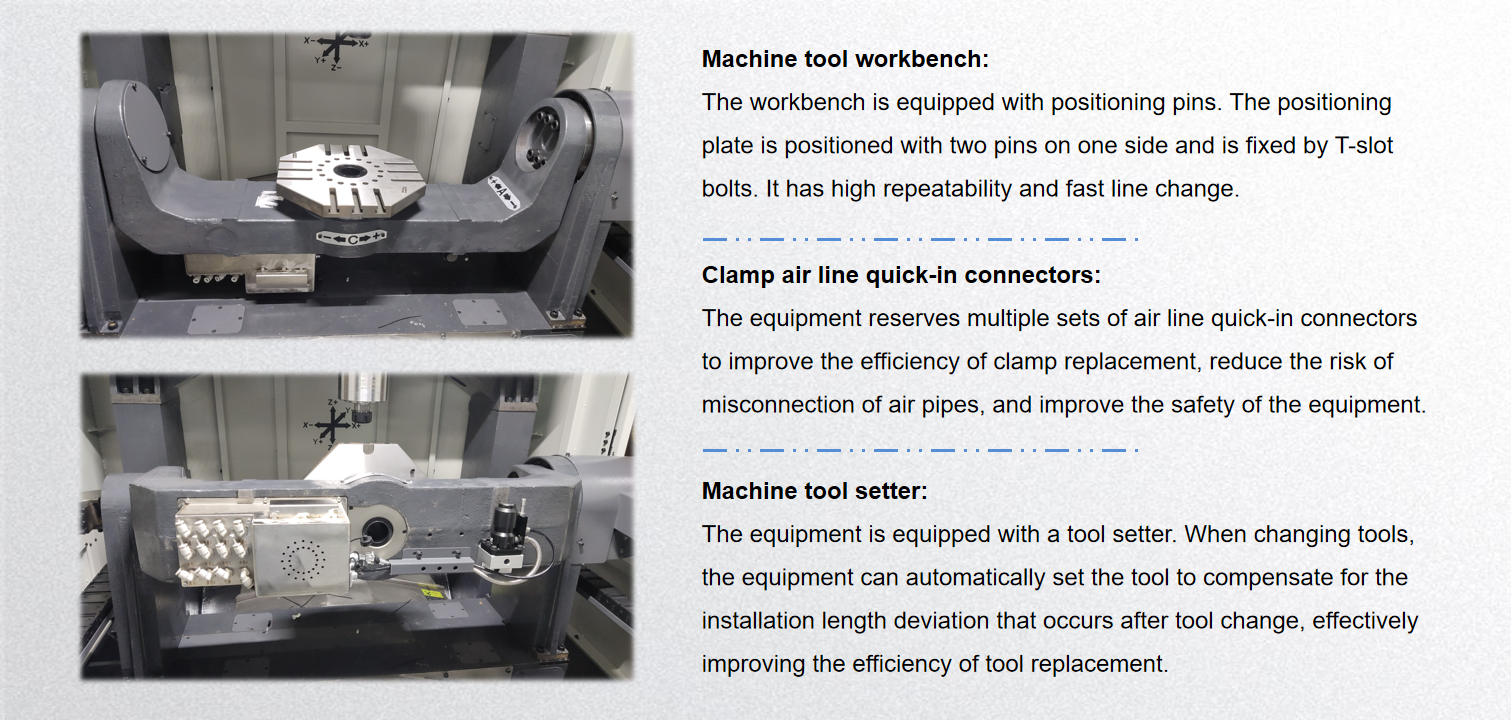

Key Features

1.Industrial-Grade Robustness

Dimensions: 2,000mm (L) × 2,600mm (W) × 3,100mm (H); weight 5,000kg.

Work Envelope: X/Y/Z strokes of 900mm/900mm/495mm, supporting components up to Φ900mm and 100kg.

Reinforced Frame: Cast iron construction minimizes vibration at 12,000 RPM, critical for machining cast iron and steel components.

2.Ultra-High Precision for Complex Geometries

Repeat Accuracy: ≤0.03mm (X/Y/Z axes), <1 arc minute (A-axis), and ≤10 arc seconds (B/C axes), ideal for deep cavities (≥150mm) and large fillets (R0.5–R2.0).

Dual-Spindle Operation: Combines rigid and floating spindles (3–16mm tool diameter) to reduce cycle times by 40% for simultaneous deburring and surface finishing.

3D Scanning Integration: Real-time trajectory correction (±0.01mm) compensates for workpiece deviations, ensuring precision in aerospace and automotive mega-parts.

3.High-Speed Automation & Smart Connectivity

Axis Speed: 660mm/s (X/Y/Z) and 148"/s (C-axis), achieving 300–400 parts/hour—4–6x faster than manual methods.

OMRON Control System: Features 6-axis linkage for complex 3D trajectories.

MES/ERP Integration: With 6-axis linkage, many years of experience in multi-axis motion control, it can be upgraded remotely and in real time, and can interact with the MES system

4.Sustainable Manufacturing Solutions

Closed-Loop Recycling: Coolant and chip recycling systems reduce waste.

Energy Optimization: Adaptive power management cuts idle consumption by 30% (total driving power: 21kW).

Safety Compliance: Enclosure with smoke detection, automatic fire suppression, and emergency stop protocols.

Sturdy Design for Heavy - Duty Operations

Measuring 2000×2600×3100mm and with a platform load weight of 100kg, the LR - ZM6C - 90 Large - Format Deburring Equipment is robustly built for heavy - duty operations. Its sturdy construction, weighing 5T, ensures stability during heavy - duty deburring, while the 21kw total driving power supports continuous operation. The machine’s design is optimized for large - scale production floors, facilitating integration into heavy - industry production lines. By bringing deburring operations in - house for large - sized parts, it reduces external processing costs and enhances quality control.

Diverse Industry Applications of the Large - Format Deburring Equipment

1.Aerospace Industry: Processes large - scale components like jet engine casings and aircraft structural parts, ensuring precise deburring for safety and performance. The Large - Format Deburring Equipment’s 0.03mm repeat accuracy guarantees component consistency.

2.Heavy Machinery: Deburrs excavator arms and tractor frames, reducing wear and tear and enhancing operational longevity. The 6 - axis system handles complex heavy - machinery part geometries effortlessly.

3.Energy Equipment: Refines wind turbine blades and nuclear power plant components, ensuring precision and reliability. The Large - Format Deburring Equipment’s multi - axis flexibility ensures thorough deburring of large - scale energy - sector parts.

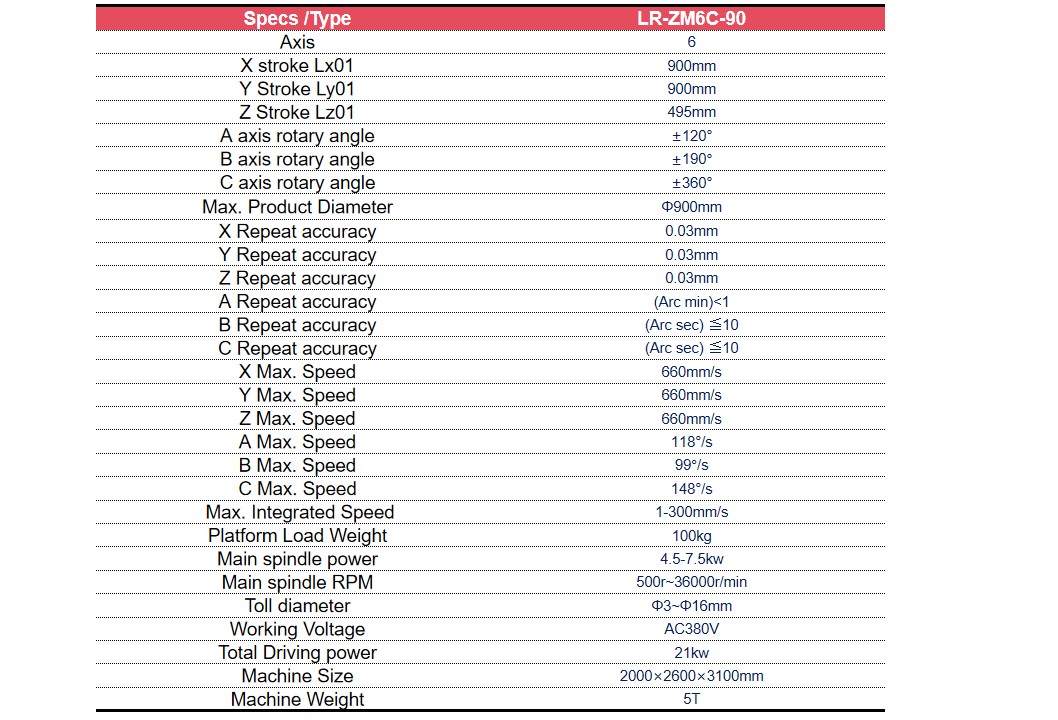

Parameter

The LR - ZM6C - 90 Deburring Machine, a premier Large - Format Deburring Equipment, is a testament to innovation for heavy - duty manufacturing. It combines precision, power, and efficiency, making it an ideal choice for businesses looking to enhance their large - scale component production. Invest in this Large - Format Deburring Equipment to experience improved productivity and uncompromised quality in your industrial operations.