- Home

- >

- News

- >

- die casting manufacturing

- >

- Die casting machine features and selection principles

Die casting machine features and selection principles

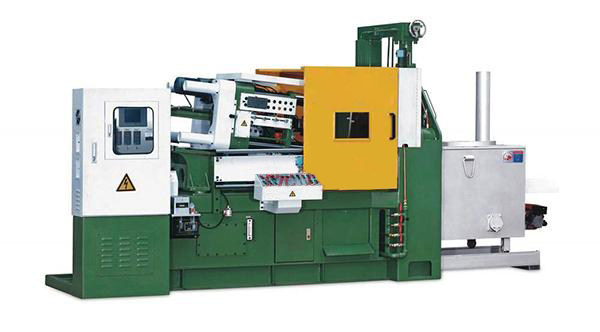

A die casting machine is a machine for pressure casting. Including hot and cold pressure chambers. After that, they are divided into two types: straight and horizontal. The die casting machine hydraulically sprays molten metal into the mold under pressure to form a solid metal casting, which is initially used for die casting. With the advancement of science and technology and industrial production, especially with the development of industries such as automobiles, motorcycles and household appliances, die casting technology has been extremely rapidly developed.

Die casting machine classification

There are many classification methods for die casting machines. They are divided into general die casting machines and special die casting machines according to the scope of use. According to the clamping force, they are divided into small machines (≤4 000 kN), medium machines (4 000 kN to 10 000 kN) and mainframes. (≥10 000 kN); usually, it is mainly classified according to the machine structure and the position of the injection chamber (hereinafter referred to as the pressure chamber) and its working conditions. It is generally divided into two types: hot press chamber and cold press chamber. According to its pressure chamber structure and arrangement, it can be divided into horizontal and vertical forms. The clamping chamber of the hot press chamber die casting machine and the cold press chamber die casting machine are the same, and the difference is that the injection and pouring mechanisms are different. The pressure chamber of the hot press chamber die casting machine is closely integrated with the furnace, and the pressure chamber of the cold press chamber die casting machine is separated from the furnace.

Hot pressing chamber

The hot chamber die casting machine refers to a die casting machine in which the injection chamber and the injection punch are immersed in molten metal, and the injection chamber communicates with the die-cast gate through the gooseneck. It is suitable for die-casting low-melting non-ferrous alloy parts such as zinc and lead. It can be widely used in automobile, motorcycle parts, instrumentation, daily hardware, household appliances and other industrial sectors. According to the structure and arrangement of the pressure chamber, it is divided into horizontal and vertical forms. The hot-press chamber is used to attach the crucible for melting metal to the machine, and the piston mechanism for hydraulically injecting the mold is installed in the crucible. The hot press chamber die casting machine uses hydraulic air to directly hydraulically inject the metal into the mold, eliminating the need for a piston mechanism.

The hot-press chamber die-casting machine is mainly used for die-casting alloys with lower melting points such as zinc and tin.

Cold pressure chamber

The cold chamber die casting machine refers to a die casting machine cold chamber die casting machine in which the injection chamber and the injection punch are not immersed in the molten metal, and the quantitative molten metal is poured into the injection chamber and then injected. The injection method is placed vertically, apparently following the injection molding of the hot die casting machine. The typical and mature vertical cold chamber die casting machine was invented in 1927 by Czech engineer Josef Polak. The horizontal cold chamber die casting machine was developed and manufactured in the early 1920s. It has more advantages, especially the one-time work cycle program is easier than the vertical cold chamber die-casting machine. After more than ten years of improvement And gradually set, widely spread in Europe and the United States.

The cold chamber die casting machine melts the metal outside the machine, and then adds the molten metal into the compression chamber with a spoon. According to the direction of the compression piston movement, it can be divided into a vertical cold press chamber die casting machine and a horizontal cold press chamber die casting machine. The molten metal in the vertical cold press chamber die casting machine is taken out into the compression chamber, and the metal is hydraulically injected into the mold by the compression piston, and the excess metal is pushed out by the other piston. The horizontal cold press chamber die casting machine is the same as the vertical type except that the piston moves in a horizontal direction. Most modern modern die casting machines are horizontal.

The cold press chamber die casting machine can die-cast a metal with a higher melting point, such as a copper alloy.

Die casting machine selection principle

The die casting machine should meet the requirements of the precision of die castings. The technical parameters of the die casting machine should meet the requirements of the production of die castings. At the same time, the accuracy and performance must meet the requirements of relevant standards. Generally, our selection principles are as follows:

Understand the type and characteristics of die casting machines;

Considering the type of alloy of die castings and related requirements, die casting machine

The selected die casting machine should meet the conditions of use and technical requirements of the die casting;

The selected die casting machine should have a certain margin in terms of performance, parameters, efficiency and safety to ensure satisfactory yield, productivity and safety;

Under the premise of ensuring the fourth point, the reliability and stability of the machine should also be considered, and the die casting machine with reasonable cost performance should be selected accordingly;

For the production scale with many varieties of die-casting parts and small production volume, under the premise of ensuring the fourth point, it is necessary to scientifically select compatible specifications so that it can cover the varieties that should be included and reduce the number of die-casting machines;

Among the various technical indexes and performance parameters of the die casting machine, the first thing to pay attention to is the injection performance. In the case of the same specification or similar specifications, it is preferred to select a model with a wide range of parameters of the injection performance;

Where possible, with mechanized or automated equipment, product quality, productivity, safe production, enterprise management, and cost accounting are beneficial;

Evaluate the effects of the selected die casting machine, including: yield, productivity, failure rate, maintenance frequency and workload, performance stability, operational reliability, and safety.