- Home

- >

- News

- >

- die casting manufacturing

- >

- The difference between die-casting mold and plastic mold

The difference between die-casting mold and plastic mold

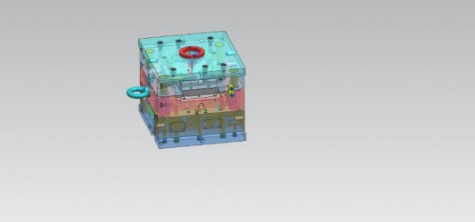

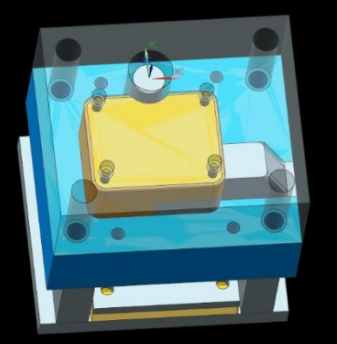

The structure of the die-casting mold and the plastic mold is actually the same. It should be said that if a plastic mold is to be made, a die-casting mold should be made. The main difference between the two is that on the sprue bushing of the feed, the sprue bush of the plastic mold is an elongated taper feed port, the diameter of the feed port is relatively small; and the feed port of the die-casting mold is relatively large. The diameter of the taper feed port of the center feed is much larger than the feed port of the plastic mold. Another feed port is a straight circular sleeve with a diameter of three or forty millimeters. This is a structure that is not available in plastic molds. In addition, plastic molds and die-casting molds are different in the steel used; plastic molds generally use 45# steel, T8, T10 and other steel materials, while die-casting molds mainly use 3Cr2W8V heat-resistant steel.

The difference between die-casting molds and plastic molds:

1. The injection pressure of the die-casting mold is large, so the template requirements are relatively thicker to prevent deformation.

2. The gate of the die-casting mold is different from the injection mold, and the high pressure of the split-flow decomposition stream is required.

3. Die-casting molds do not require quenching because the temperature in the cavity during die-casting exceeds 700 degrees.

It is equivalent to quenching once. The cavity will become harder and harder. The general injection mold should be quenched to above HRC52.

4. Die-casting molds should be nitrided in the general cavity to prevent the alloy from sticking to the mold cavity.

5. The general die-casting mold is relatively corroded, and the outer surface is generally blue.

6. Compared with the injection mold, the active matching part of the die-casting mold (such as the core puller) has a larger clearance.

Because the high temperature of the die casting process will cause thermal expansion. If the gap is too small, the mold will be stuck.

7. The parting surface of the die-casting mold has higher requirements, because the fluidity of the alloy is much better than that of the plastic.

It is very dangerous for the high temperature and high pressure stream to fly out of the parting surface.

8. The injection mold is generally vented by the ejector pin, the parting surface, etc., and the die casting mold must be opened with a venting groove and a slag collecting bag (collecting the cold material head);

9. Inconsistent molding, injection molding die injection speed, a section of injection pressure. Plastic mold is usually divided into several injections, pressure.

10. Die-casting mold is a two-plate mold (I have not seen a 3-plate die-casting mold for a while). The mold is opened at a time. The product structure of the plastic mold is different.

3 plate molds are common, the number of mold opening and sequence are matched with the mold structure. Our die-casting molds usually do not use square thimbles, cylinders,

The oblique pin (high temperature and good fluidity of the solution) is easy to be stuck, resulting in unstable mold production.

In addition, plastic molds and die-casting molds are different in the steel used; plastic molds generally use 45# steel, T8, T10 and other steel materials, while die-casting molds mainly use 3Cr2W8V heat-resistant steel.