- Home

- >

- News

- >

- die casting manufacturing

- >

- With an annual income of 1.5 billion yuan, how does Dongfeng Auto Parts Factory do it?

With an annual income of 1.5 billion yuan, how does Dongfeng Auto Parts Factory do it?

In the east of Shiyan City, there is a company near the railway station. It was established in 1969. With the reform and opening up, it has been continuously adjusting its development direction and has continued to grow. From the original wood processing plant, it has become a revenue of 1.5 billion this year. Automotive Trim Company, it is Dongfeng Yanfeng (Shiyan) Automotive Trim Co., Ltd.

It has undergone 49 years of wind and rain, 6 times changed its name, turned into a beautiful butterfly, and danced on this land of Shiyan.

Military factory in the seventies and eighties

In 1969, with the country's layout of the automobile industry, it was decided to build a second automobile manufacturing plant. At that time, the construction of the factory mainly considered the needs of war and military. The second automobile was actually a large heavy industry group combining automobile and military.

Shiyan City is located at the junction of Hubei, Chongqing and Shaanxi provinces. It is deep in the abdomen of China. The terrain is surrounded by mountains. Only one railway and highway are coming in. It conforms to the policy of building factories, scattered and concealed at that time. Factory safety.

There are many professional factories under the Second Automobile Co., Ltd., which produce different parts of the car to meet the integrated assembly of the car. These factories are located in various directions of Shiyan City.

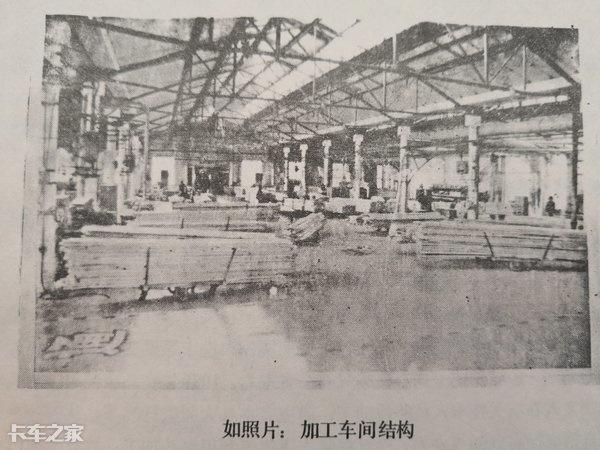

At that time, the smallest professional factory of the Second Automobile was called the wood processing factory, code 5747, which reflected the positioning of the military factory and the characteristics of the historical era.

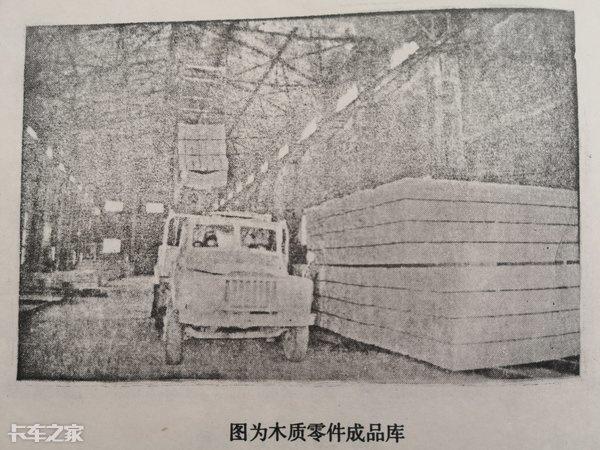

At that time, the main task of the Siqi Plant was to provide wood-based car floor, wood, slats and other wooden parts for the second steam. The wood raw material comes from the northeast of 3,000 kilometers, and the railway station is less than 500 meters behind the factory building, which satisfies the continuous supply of raw materials.

This is the original Dongfeng Yanfeng (Shiyan) Auto Trim Systems Co., Ltd., which belonged to the planned economy at that time. The main production relied on manpower. The main task was to meet the production needs of the Second Automobile, and it was not possible to calculate the annual income.

Turning to the market economy in the 1990s

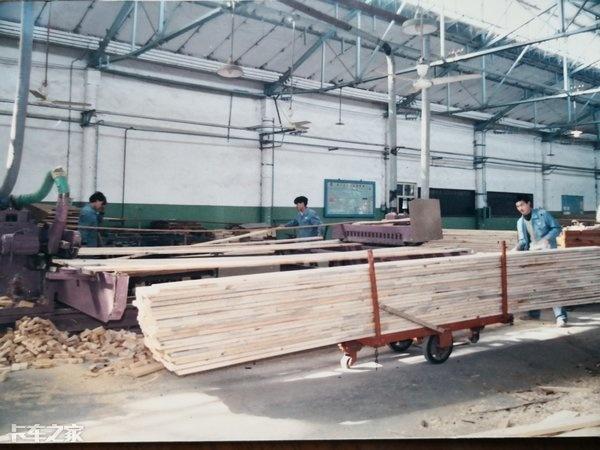

Gradually, with the deepening of the country's reform and opening up, China's second automobile manufacturing plant was renamed Dongfeng Automobile Manufacturing Factory. The wood processing factory also kept up with the characteristics of the times. In 1986, the factory manager responsibility system was established and renamed in 1992. It is a non-metallic parts processing factory.

The factory quickly aimed at the market's promising interior and exterior decoration of the car and timely adjusted the product structure. From then on, the factory entered an important period of rapid development.

During this period, the non-metallic parts factory won the project of the Fukang sedan door guard assembly of the French Shenlong Company, which took the first step towards internationalization.

After entering the 1990s, in addition to the military and special purposes, the state basically stopped the practice of issuing command plans, and the production and operation activities of enterprises were completely driven by market demand. With the end of the planned economy era, brands must keep up with the market situation if they continue to grow.

During this period, the term “environmental protection” gradually approached people's horizons. The person in charge of the factory felt that the processing of automobile parts by wood was not a long-term road for enterprise development. The development of the factory must also move toward marketization. At the end of 1996, the non-metallic parts factory was renamed as Dongfeng Automobile Non-metal limited. The company marks a professional manufacturer of the factory system to move toward a corporatization system under market economy conditions.

Sino-foreign joint venture in the 21st century realizes capital leap

It is said that the real departure from wood processing production should be counted from 2000 onwards. This year, Dongfeng Motor Non-Metal Co., Ltd. completely abandoned the operation of wood processing parts and components, and also made a new adjustment to the product structure and development strategy. Automotive Interior Parts Co., Ltd., changed its name to Dongfeng Electronic Technology Co., Ltd. Automotive Trim Systems Co., Ltd. a year later, completely eliminated the wooden products business, concentrated on the development of automotive interior and exterior system products, and achieved the company's capital operation.

In the process of development, in order to catch up with the world's advanced level, Dongfeng Electronic Technology Co., Ltd. Automotive Trim Systems Co., Ltd. actively explored the joint venture road. In 2005, it took a solid step toward internationalization.

At that time, Dongfeng Visteon (Shiyan) Automotive Trim Systems Co., Ltd. was established by Dongfeng Electronic Technology Co., Ltd. and Dongfeng Visteon Automotive Trim Systems Co., Ltd., which was the company's fifth name change.

During this period, the company completed the development and production of more than 100 interior and exterior parts of the Dongfeng Commercial Vehicle D310 model, developed a full set of D310 models of interior lighting products, and at the same time, modular development of the instrument panel, "D310 instrument panel module development and The project management application won the first prize of the Dongfeng Limited Parts Business Unit Science and Technology Innovation Project, and the “dashboard modularization” research and development has become the core brand of the company's independent research and development.

Entering the new era, the level of intelligence is improved

In June 2016, due to the adjustment of the joint venture's US Visteon business, the company name was changed from “Dongfeng Visteon (Shiyan) Automotive Trim Systems Co., Ltd.” to “Dongfeng Yanfeng (Shiyan) Automotive Trim Systems Co., Ltd.”. After years of development, it has realized the R&D and manufacturing capabilities of systematic development and modular supply. It synchronizes design with customers, synchronizes costs and synchronizes quality, and provides more efficient and convenient value-added services for different customers.

Nowadays, Dongfeng Yanfeng (Shiyan) Automotive Trim Systems Co., Ltd. has branches in Shiyan, Wuhan, Fuyang, Zhengzhou and Dalian. The annual output value has also risen from the original millions of dollars, achieving nearly 100 million yuan per year. increase.