Aluminum alloy air pressure fixed quantity holding furnace

Product origin :China

Delivery time :30 Days

It is a new type of non-crucible furnace. Fully sealed, insulated and fixed system for handling aluminum fluids. The system can be taken from below the aluminum liquid in the tank at any time. All aluminum fluid can be automatically delivered to the die casting machine or mold. No air contact during the process, no pollution and reduced oxidation loss.

Excellent utilization and Production capacity :

1,Using the quantitative control software,quantitative accuracy of the quantitative furnace to achieve ±1.5%.

2,Our quantitative furnace refractory

insulation material using Germany, the United States and other well-known brands combined sealed design, reduce energy consumption,compared with the traditional holding furnace, can reduce 80%,the holding temperature error is less than±2℃。

Our quantitative furnace,design and manufacture according to European mechanical safety standard,choose international brand components、Siemens control system,double protection,safety interlock mechanism,safety emergency stop device, ensure the safety and reliability of equipment operation,comprehensive guarantee the operator safety.

Characteristic advantage:

Our quantitative furnace is a new Non crucible furnace, A clean sealed thermal insulation and quantitative system for handling liquid aluminum.Quantitative system can anytime from the pool below the liquid aluminum take liquid, all liquid aluminum can automatic delivery to die casting machine or mold ,no air contact during quantification, no pollution and Reduce oxidation burn loss.

The quantitative accuracy:﹤±1.5%

Holding temperature error: ﹤±2℃

The quantitatove time : 2-10s

Metal burn out rate: ﹤0.1%

Energy consumption of electrical energy : Common soup system 1/3

The high quality liquid aluminum :take the material at the bottom of the liquid aluminum, the liquid aluminum quality guaranteed to the greatest extent.

Enclosed Furnace chamber :The oxide film formed on the surface of liquid aluminum is guaranteed not to be destroyed,oxidation slag inclusion few,Slag removal time is greatly reduced.

The service life :brasque、electrical components normal use for more than 10 years.

Online deaerating: For high - end die casting aluminum quality requirements.

Parameters of the stored: Mold process parameter storage function,Change the mold one - click parameter storage and reading function.

The structure design:Easy to install and debug.

High efficiency:Constant quantity holding furnace,compared with other feeding methods,More efficient,there is no standby time,and on-call,greatly improve production efficiency.

Security guarantees:use electrical safety,machinery safety,mechanical self-locking、electric interlocking,Protection for incorrect operation and other security measures.

Temperature control: The main control cabinet adopt air-conditioning thermostatic control system.

Configuration parameter:

Mold | Capacity (Kg) | (kw) | Thermal Power (kw/h) | Installation dimensions (L*W*Hmm) | Lifting height (mm) | Suitable for die casting machine model |

DS-1000 | 800 | 30 | 5 | 3050*2050*2880 | 200 | 800T-1200T |

DS-1500 | 1200 | 36 | 7 | 3150*2280*3280 | 400 | 1200T-1650T |

DS-2000 | 1600 | 48 | 9 | 3650*2680*3280 | 400 | 1650T-2200T |

DS-2500 | 2000 | 54 | 10 | 3650*2680*3500 | 400 | 2200T-3000T |

DS-3000 | 2400 | 60 | 12 | 3650*2680*3580 | 600 | 3000T-4400T |

DS-3500 | 2800 | 60 | 13 | 4660*2880*3820 | 600 | 4400T the above |

The working principle of

When quantitative furnace transport liquid aluminum,over pressure is generated in the furnace chamber,make lift pipe level of aluminum in the riser keeps rising,until stop the liquid aluminum to the probe position.When the die casting machine needs liquid aluminum,the quantitative furnace receives signals and respond, continue to increase the pressure in the furnace chamber,timely delivery of liquid aluminum;When the liquid aluminum reaches a predetermined amount,reduce furnace chamber pressure,stop the quantitative process,return the liquid aluminum to the probe position,the quantitative furnace waits for the next quantitative signal.

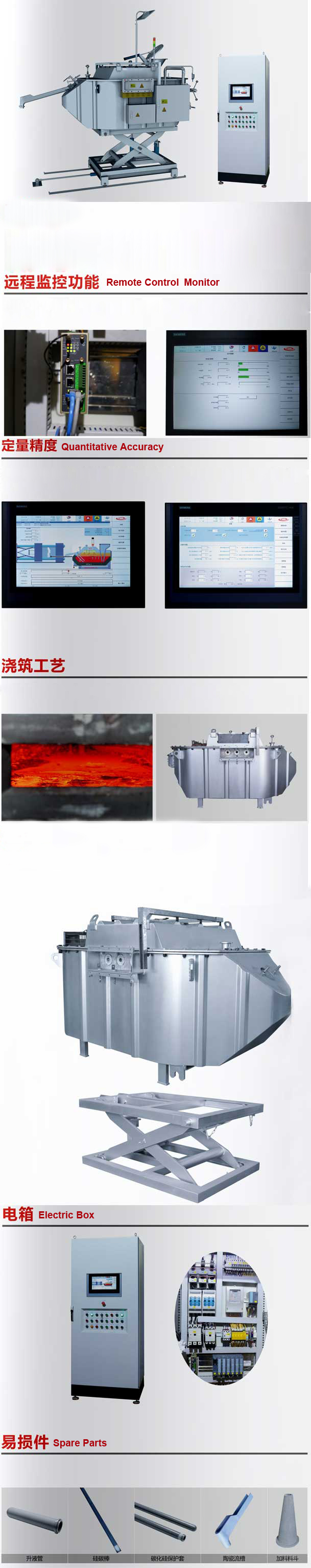

Remote monitoring function

Remote monitoring software, can monitor the pressure in furnace chamber in real time,aluminum liquid temperature and measuring the running state of the quantitative furnace,can remote modification、set the parameters,monitor fault information online,

quick dispose fault.

The quantitative accuracy

The latest version of quantitative control software using a new method of conversion make the quantitative furnace the quantitative accuracy to achieve±1.5%. and,by setting different correction coefficients,can compensating pressure fluctuation,improve sustainability.

Pouring process

Our Constant quantity holding furnace Selection of refractory brasque and Pouring process can effectively prevent the production of corundum tumor,extend the life of the furnace.