DS-4010-3 High-Speed Polishing Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

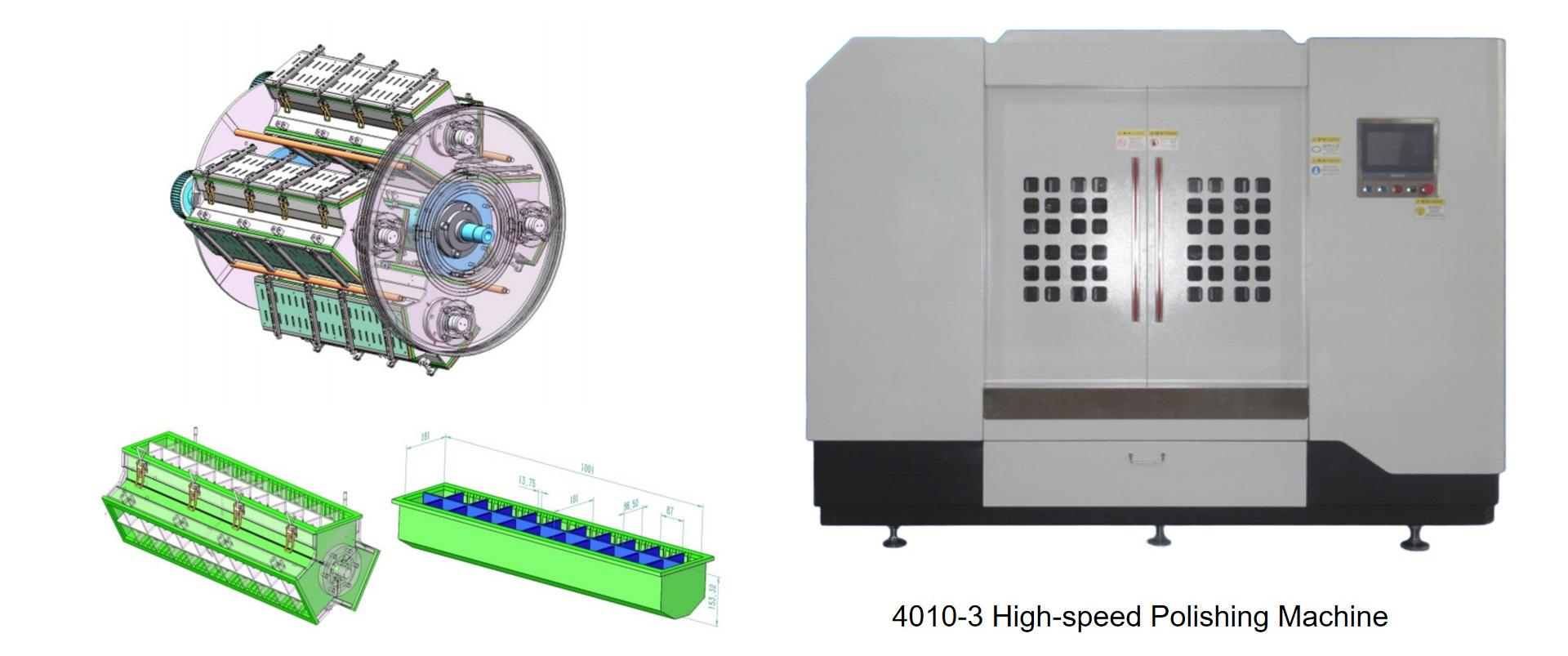

The DS-4010-3 Centrifugal Finishing Machine is a mid-range model designed for medium-sized workpieces and batch production.

Equipped with a 7.5kW motor and advanced dynamic balancing technology, it handles materials such as titanium alloys, stainless steel, and copper alloys. Specializing in precision deburring, edge radiusing, and high-quality surface finishing, the Centrifugal Finishing Machine is suitable for aerospace components, industrial tools, and consumer electronics manufacturing.

Core Functional Features

1.High-Torque Processing System

--7.5kW Permanent Magnet Motor: Provides robust torque for continuous processing of hard materials. The Centrifugal Finishing Machine integrates an optional water-cooling system to ensure stable operation during extended use.

--Dynamic Balance Optimization: The Centrifugal Finishing Machine controls vibration levels within industry-accepted thresholds, ensuring uniform surface treatment for complex geometries such as turbine blades or multi-hole components.

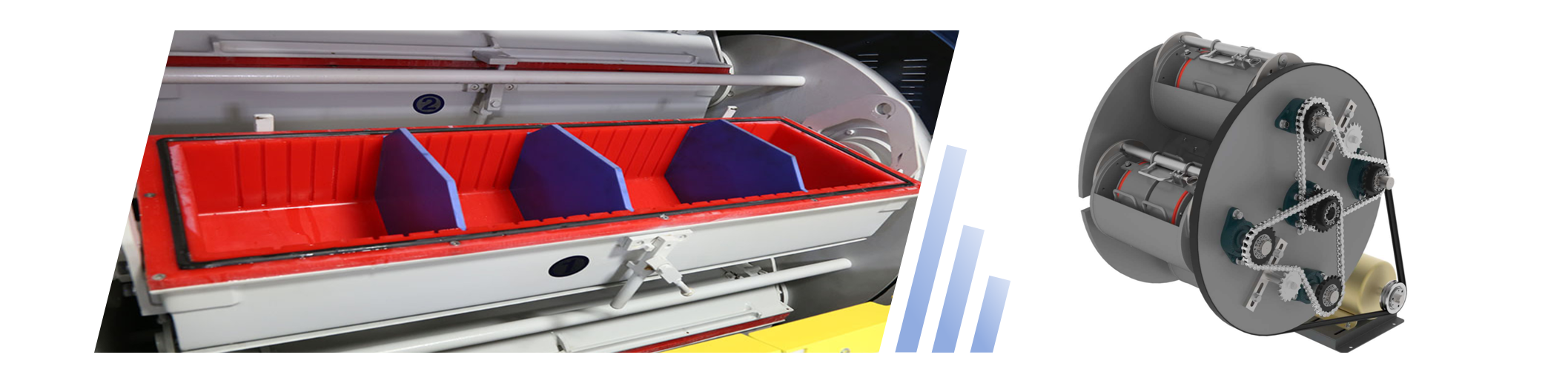

2.Multi-Media Compatibility

--Rough Polishing: Reduces surface roughness to functional levels.

--Fine Polishing: Achieves mirror finishes for aesthetic or functional requirements.

--Hybrid Abrasive Solutions: The Centrifugal Finishing Machine supports ceramic balls, resin-based media, and biodegradable abrasives. Example workflows:

3.Intelligent Operational Controls

--Real-Time Diagnostics: The Centrifugal Finishing Machine monitors operational parameters to detect potential component wear or overload risks, reducing unplanned downtime.

--Energy Efficiency Mode: Reduces standby power consumption for cost-effective operation of the Centrifugal Finishing Machine.

Industrial Applications

1.Aerospace Manufacturing

--Turbine Blade Finishing: Removes burrs and polishes surfaces to meet functional requirements for aerospace components.

-- Landing Gear Components: Smooths actuator surfaces to reduce operational friction.

2.Tool and Hardware Production

--Industrial Tool Polishing: Processes high volumes while maintaining material integrity.

--Consumer Electronics: Achieves brushed or mirror finishes on metal casings.

3.Medical Device Fabrication

--Implant Surface Preparation: Ensures clean, burr-free surfaces for medical applications.

--Surgical Instrument Cleaning: Removes contaminants for sterilization readiness.

Key Advantages

--Adaptive Hopper Design: Adjustable compartments accommodate a wide range of workpiece sizes.

--Dry Processing: Eliminates wastewater generation, supporting environmentally conscious manufacturing.

--Safety Compliance: Includes overload protection, emergency stop functions, and safety sensors.

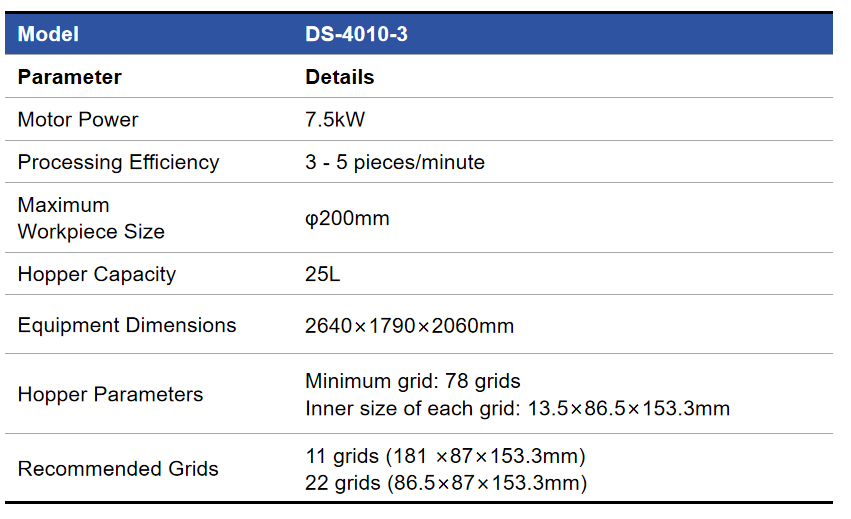

Technical Specifications

The DS-4010-3 Centrifugal Finishing Machine offers a balance of precision and productivity, providing a cost-effective solution for industries requiring reliable surface finishing. Its compatibility with multiple media types and energy-efficient design align with modern manufacturing demands.