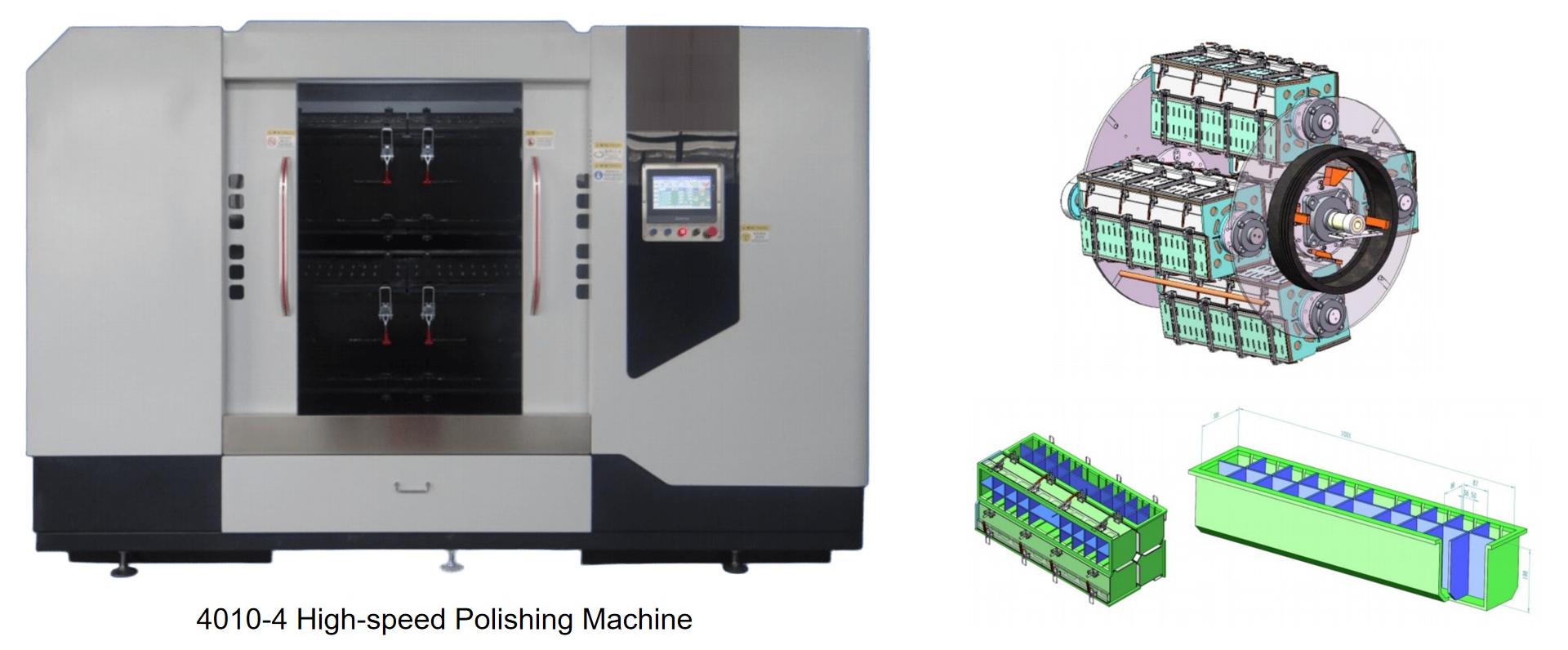

DS-4010-4 High-Speed Polishing Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The DS-4010-4 Industrial Centrifugal Polisher is a heavy-duty model engineered for large workpieces and high-volume production.

Equipped with a 15kW industrial-grade motor and a 35L hopper, this Industrial Centrifugal Polisher is designed for demanding applications such as automotive wheel hubs, industrial valves, and heavy machinery components. Its robust construction and automated integration capabilities make it ideal for continuous operations in industries requiring precision and durability.

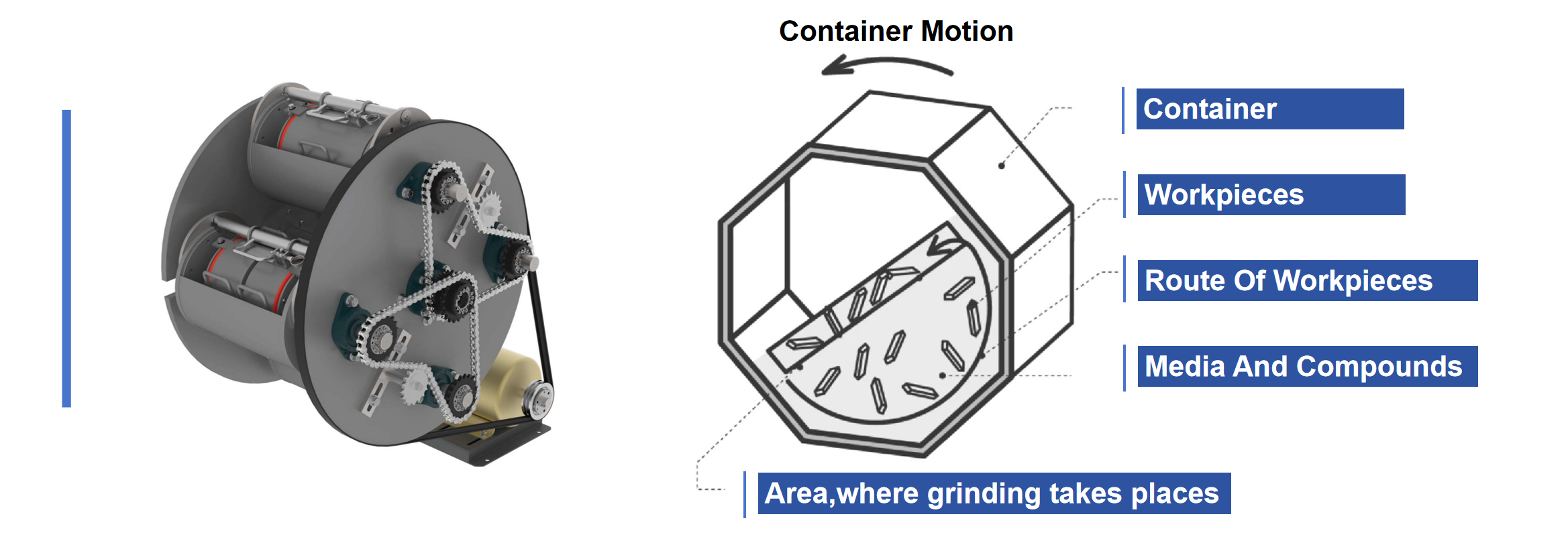

Core Technologies

1.Heavy-Duty Processing System

--15kW Industrial Motor: Delivers 210 N·m of torque for processing large workpieces up to φ250 mm. Maintains stable performance under prolonged operation, with optional temperature control to prevent overheating.

--Reinforced Hopper Design: Built with 16Mn steel plates, offers enhanced wear resistance, extending service life to over 10,000 hours.

2.Automation and Precision

--Robotic Arm Integration: Supports optional robotic loading/unloading systems, enabling seamless integration with production lines and reducing manual intervention.

--Six-Axis Synchronization: Ensures hopper and spindle speeds are synchronized with ≤0.5% error, achieving consistent surface finishes across batches.

3.Energy Efficiency

--Variable Frequency Drive (VFD): Optimizes power consumption based on load conditions, reducing energy usage by 15% compared to fixed-speed systems.

--Heat Recovery System: Captures residual heat from the Industrial Centrifugal Polisher for facility heating or secondary processes.

Industrial Applications

1.Automotive Manufacturing

--Wheel Hub Polishing: Achieves uniform matte or mirror finishes on aluminum alloy wheels, enhancing aesthetic and corrosion-resistant properties.

--Engine Components: Removes burrs and improves surface smoothness for critical parts like crankshafts and connecting rods.

2.Energy and Heavy Machinery

--Valve Surface Treatment: The Industrial Centrifugal Polisher deburrs and polishes large industrial valves, ensuring leak-free sealing surfaces.

--Construction Equipment: Prepares surfaces of excavator components for protective coatings, extending service life.

3.General Metalworking

--Batch Processing: Handles high volumes of cast iron or steel parts with minimal downtime.

--Complex Geometries: Processes irregularly shaped components (e.g., gears with internal cavities) without custom fixtures.

Key Advantages

--Durability: The Industrial Centrifugal Polisher is built with industrial-grade materials to withstand harsh operating environments.

--Dry Processing: Eliminates wastewater and chemical slurries, complying with ISO 14001 environmental standards.

--Safety Compliance: Features overload protection, emergency stop functions (2-second shutdown), and enclosed safety guards.

The DS-4010-4 Industrial Centrifugal Polisher combines heavy-duty performance with automation readiness, making it a cost-effective solution for industries requiring high throughput and reliability. Its modular design and energy-efficient operation align with modern manufacturing sustainability goals.