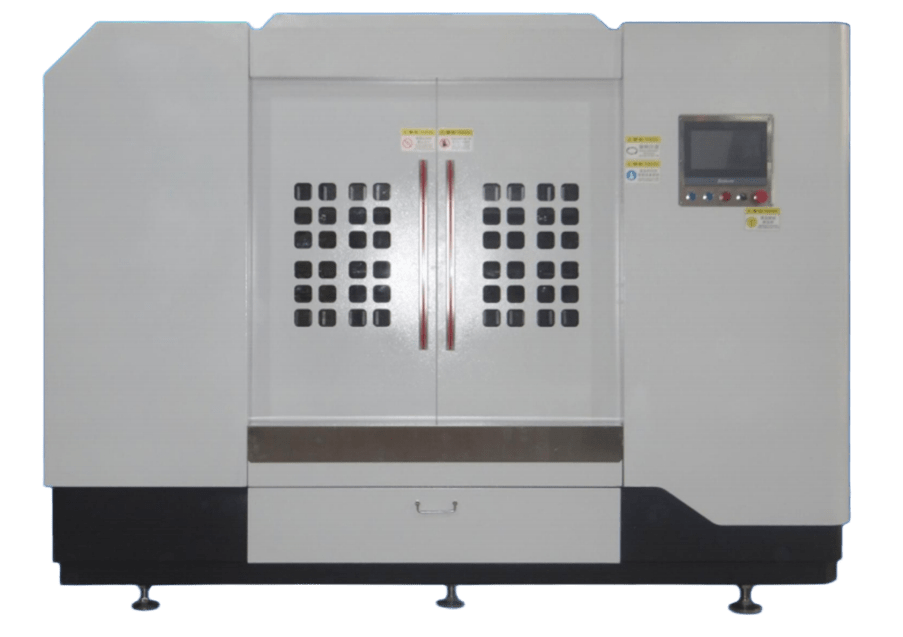

DS-4010-5 High-Speed Polishing Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The DS-4010-5 Industrial Centrifugal Polisher is the flagship model of the DS-4010 series, engineered for ultra-large workpieces and high-volume production.

` Equipped with an 18.5kW high-torque motor and a 50L hopper (expandable to dual-hopper configuration), this Industrial Centrifugal Polisher is designed for demanding applications such as wind turbine components, shipbuilding parts, and heavy machinery. Its robust construction, real-time monitoring, and adaptive control systems ensure precision and reliability in continuous operations.

Core Technologies

1.Ultra-High Torque Processing System

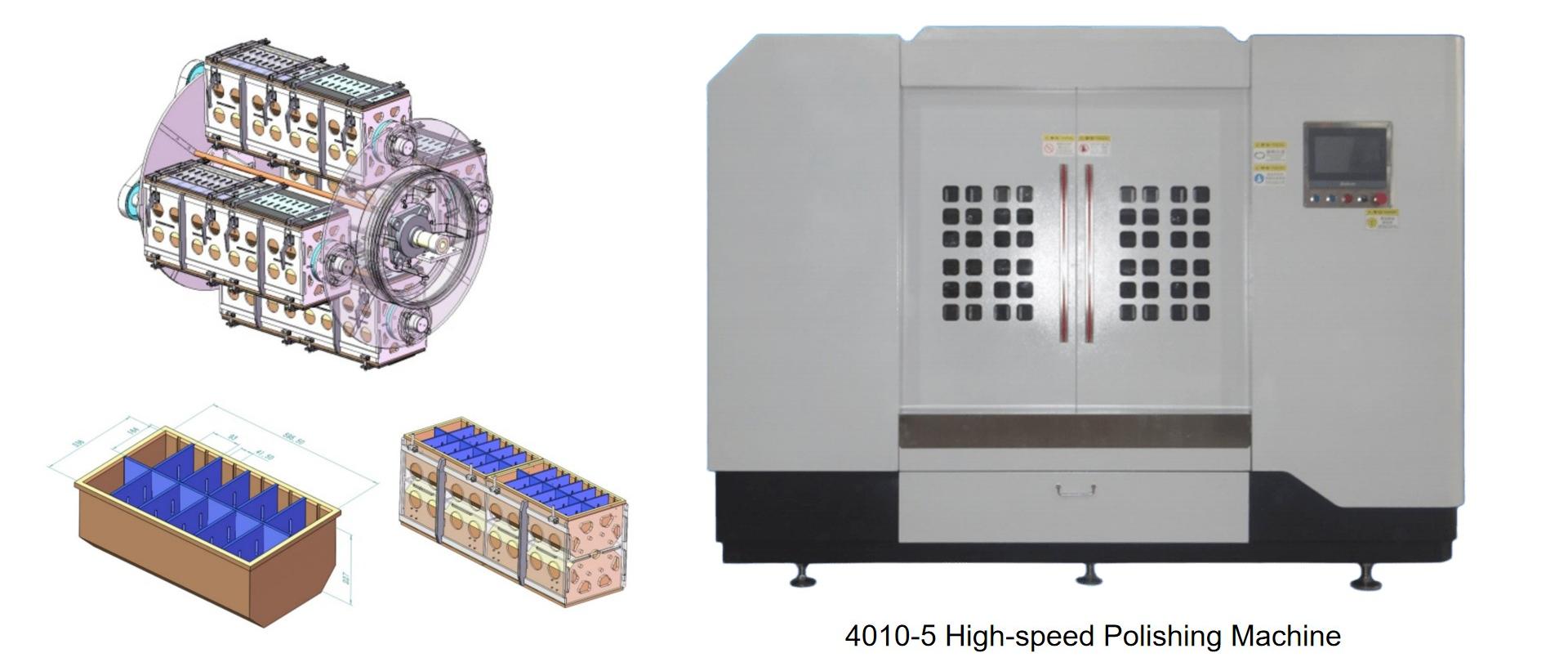

--18.5kW Industrial Motor: Delivers 980 N·m of peak torque, capable of processing workpieces up to φ300 mm. The Industrial Centrifugal Polisher maintains stable performance under extreme loads, with ceramic-coated spindles extending maintenance intervals to 5,000 hours.

--Dual-Hopper Parallel Mode: Doubles throughput by operating two 50L hoppers simultaneously, ideal for large-scale production of heavy industrial components.

2.Precision Control Systems

--Real-Time Sensor Monitoring: Integrated sensors track spindle speed, vibration, and temperature, enabling proactive adjustments to maintain consistent processing quality.

--Adaptive Parameter Adjustment: Dynamically optimizes rotational speed and media pressure based on material properties, improving efficiency by 10-15% compared to fixed settings.

3.Sustainability and Durability

--Regenerative Braking System: Recovers kinetic energy during deceleration, reducing overall power consumption.

--Redundant Safety Systems: Dual-circuit power supply and backup braking modules ensure operational stability.

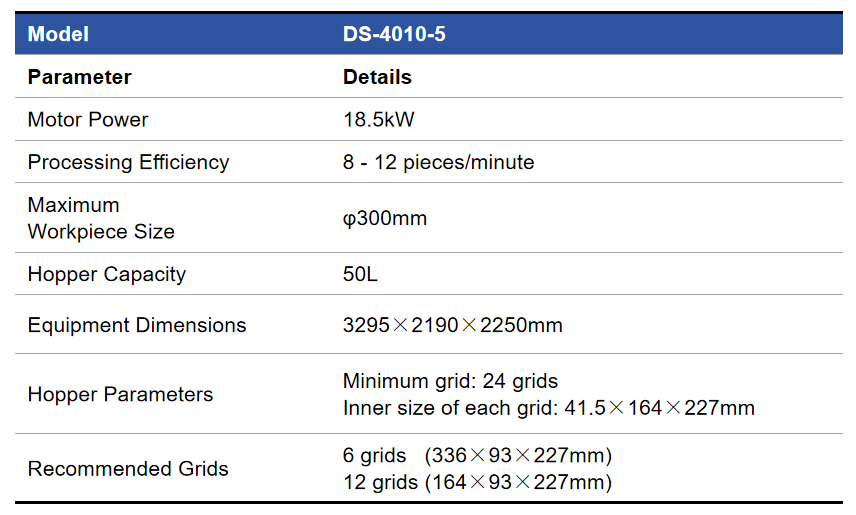

Technical Specifications

Industrial Applications

1.Wind Energy Sector

--Turbine Bearing Polishing: The Industrial Centrifugal Polisher achieves ultra-smooth surface finishes (Ra ≤0.1 μm) on large-diameter bearings, reducing friction and enhancing operational lifespan.

--Blade Connection Components: Processes complex geometries with tight tolerances, ensuring compliance with structural engineering standards.

2.Shipbuilding and Marine Engineering

--Propeller Surface Treatment: Removes oxidation layers and polishes marine-grade alloys, improving hydrodynamic performance.

--Engine Component Finishing: Prepares crankshafts and piston rods for anti-corrosion coatings.

3.Heavy Machinery

--Large Castings: Deburrs and polishes cast iron or steel parts with minimal downtime.

--Gear Systems: Processes hardened steel gears with dimensional accuracy within ±5 μm.

Key Advantages

--Scalability: The Industrial Centrifugal Polisher supports dual-hopper expansion for high-volume production, doubling throughput without additional floor space.

--Eco-Friendly Design: Dry processing eliminates wastewater, aligning with environmental regulations.

--Operational Reliability: Industrial-grade components and safety systems ensure stability in continuous production.

The DS-4010-5 Industrial Centrifugal Polisher combines high-torque capabilities with precision control, making it a strategic choice for industries requiring efficient large-scale surface finishing. Its modular design and energy-efficient operation align with modern manufacturing demands.