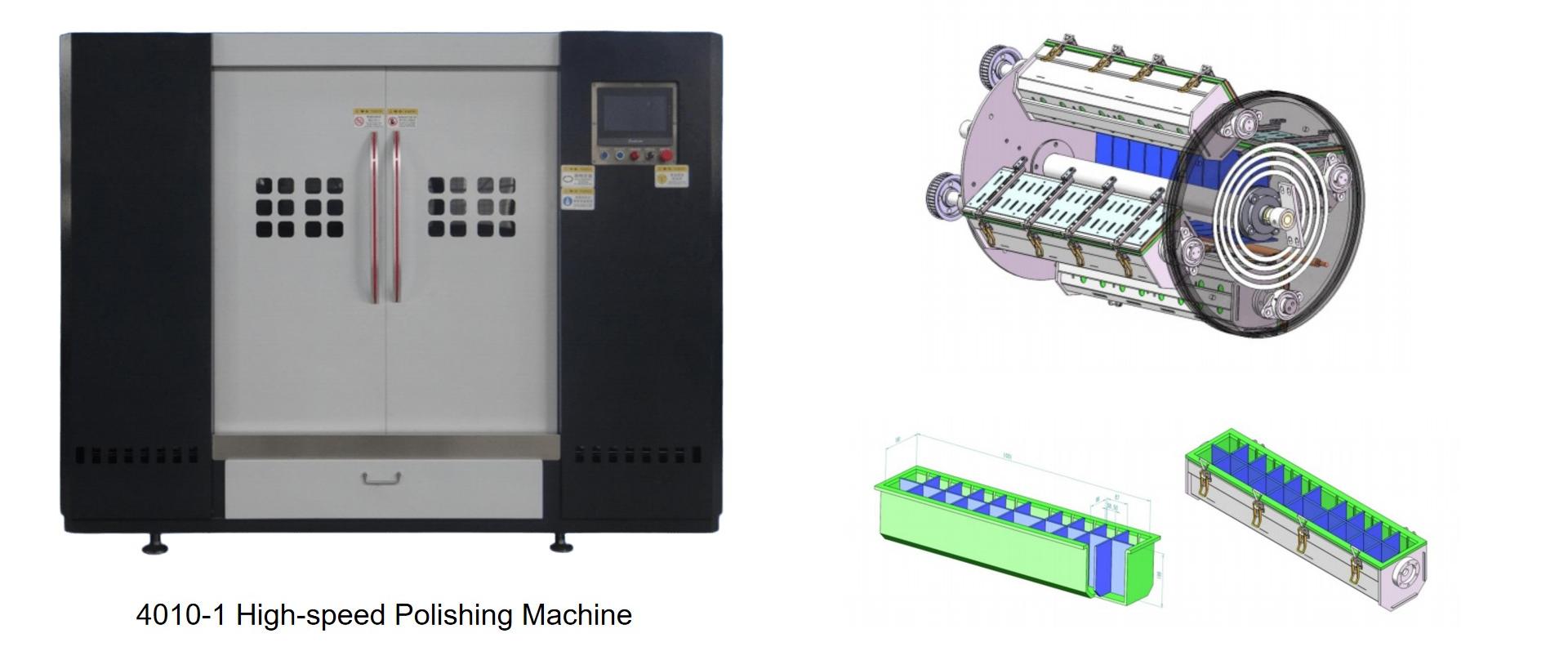

DS-4010-1 High-speed Polishing Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The DS-4010-1 High-Speed Centrifugal Finishing Machine is a compact, entry-level surface treatment system engineered for small to medium-sized workpieces.

It excels in deburring, edge radiusing, rough-to-mirror polishing, and precision finishing for materials such as zinc alloys, aluminum alloys, and stainless steel. Featuring modular hopper configurations and a dry-processing design, this machine is tailored for industries like electronics, medical devices, and precision hardware manufacturing. Its closed-loop operation eliminates wastewater generation while ensuring energy efficiency and compliance with stringent environmental regulations.

Core Technologies

Industrial Applications

1.Electronics Manufacturing

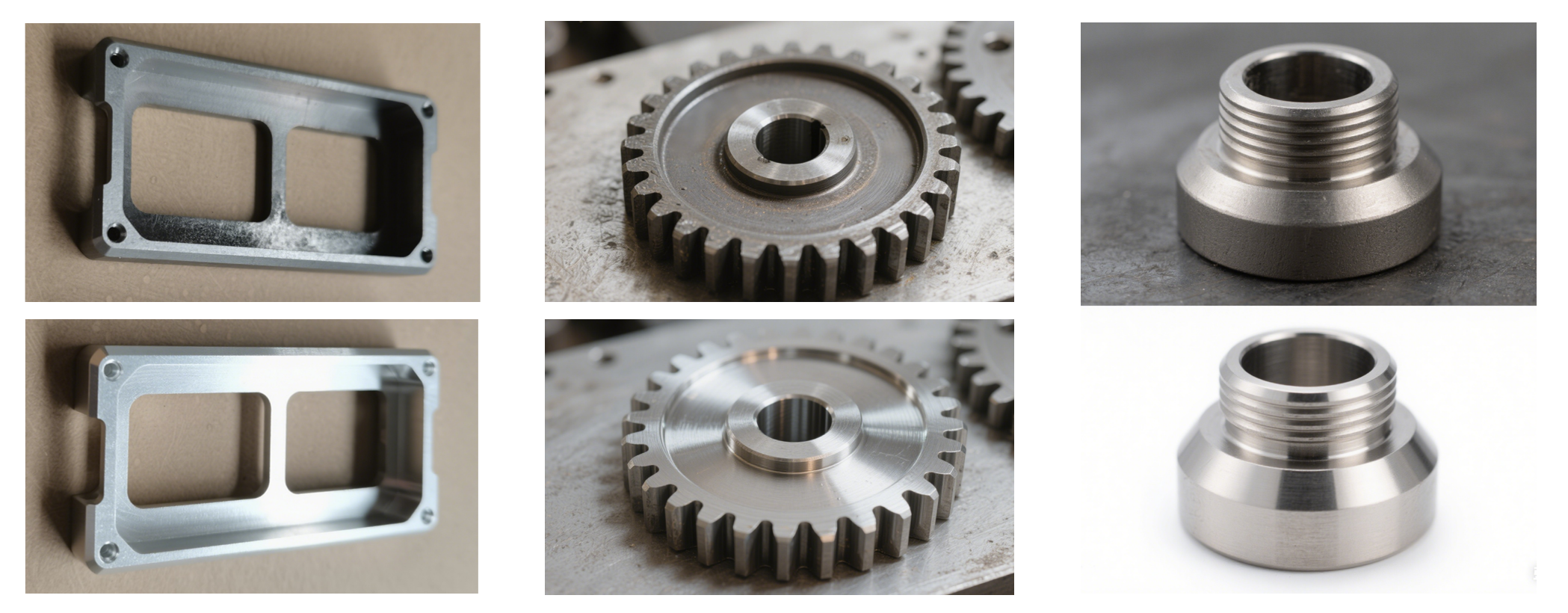

--Aluminum Alloy Housings: Achieve mirror finishes for smartphone frames and connectors.

--Micro Components: Utilize hexagonal grid inserts to polish pins and terminals without cross-contamination.

2.Medical Device Production

--Surgical Instruments: Remove microburrs and contaminants from stainless steel forceps, ensuring compliance.

--Implant Surface Preparation: Deliver biocompatible-ready finishes free of chemical residues.

3.Precision Hardware

--Gears and Bushings: Achieve edge radii and reduce surface roughness.

--Complex Geometries: Process bent tubes or multi-cavity parts without custom fixtures, reducing setup time.

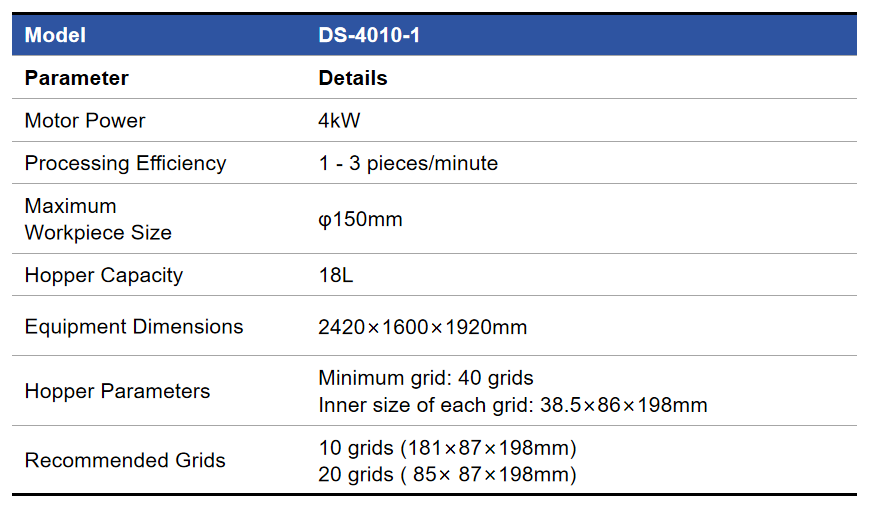

Technical Specifications

Industry Relevance and User Benefits

The DS-4010-1 centrifugal barrel polisher stands out for its energy efficiency (average power consumption: 4.2kW·h) and low operational costs.Its user-friendly design requires only short-time training for operators, significantly lowering labor thresholds compared to traditional equipment.The quick parameter adjustment feature supports flexible production shifts between different processes, making it an optimal choice for SMEs seeking cost-effective, high-precision surface finishing solutions.

This model’s adaptability to diverse materials and processes—combined with its robust safety and environmental compliance—positions the centrifugal barrel polisher as a reliable asset in industries demanding both quality and sustainability.