- Home

- >

- News

- >

- Industry Insights

- >

- A Practical Guide to Deburring Methods for Die-Cast Parts

A Practical Guide to Deburring Methods for Die-Cast Parts

Since burrs are an unavoidable manufacturing byproduct, selecting the right deburring method is critical for final product quality. This choice is not a one-size-fits-all decision; it depends on factors like part material, structural complexity, production volume, and final quality requirements. This guide systematically analyzes the mainstream deburring methods for die-cast parts.

I. Mechanical Contact Deburring

This is the most widely used category of methods, which directly cut, grind, or scrape away burrs through physical contact.

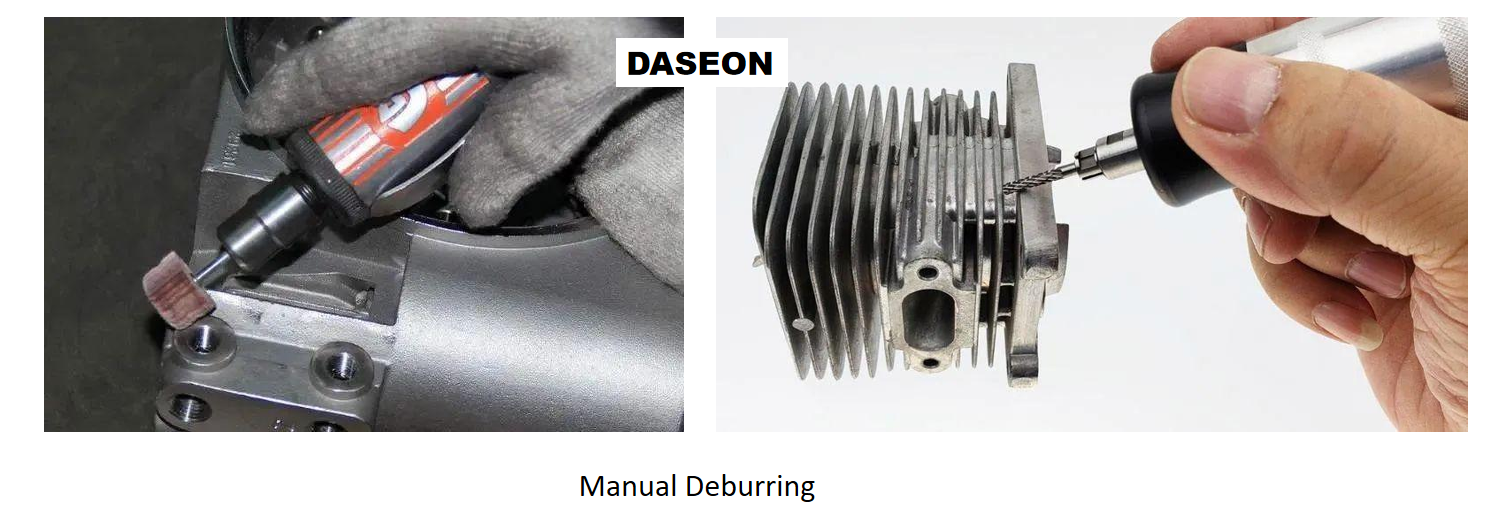

1. Manual Deburring

This is the most traditional and common method, where operators use tools like files, sandpaper, and scrapers for manual trimming.

--Advantages: High flexibility and low tool cost, suitable for small batches, simple parts, or applications with low precision requirements.

--Disadvantages: Highly labor-intensive, extremely low efficiency, and quality is entirely dependent on worker experience, leading to inconsistency. It is ineffective for hard-to-reach burrs in cross-holes or deep holes. Due to its high overall cost and unstable quality, it is gradually being replaced by automated methods.

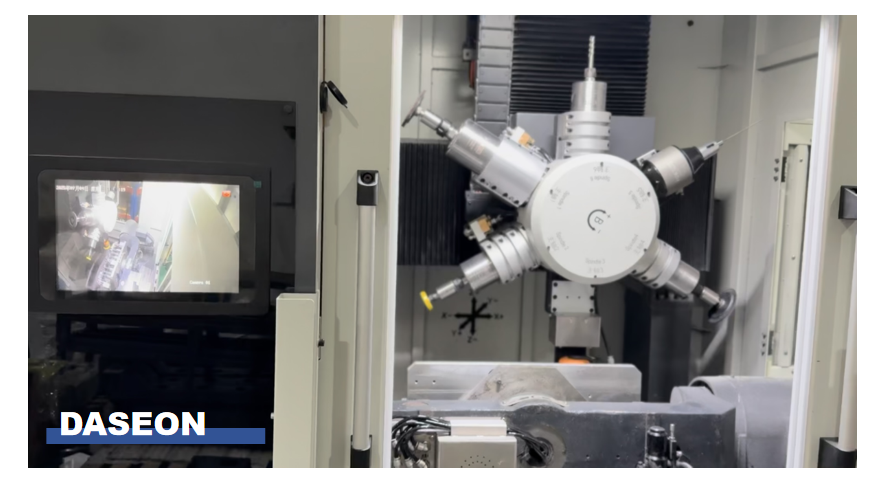

2. CNC/Robotic Deburring:

The Perfect Union of Precision and Efficiency

As the leading automated solution for high-precision manufacturing, CNC and robotic deburring overcomes the limitations of manual processing. It utilizes programmed CNC machines or multi-axis industrial robots with specialized tools to achieve consistent, high-quality finishing on complex parts.

--Core Characteristics:The process is defined by precision control. Pre-programmed paths guide tools like rotary burrs and abrasive brushes along part contours. Advanced systems often integrate force control or a floating spindle, which provides compliance, allowing the tool to automatically adapt to minor part variations and complex surfaces. This ensures burrs are removed effectively without damaging the workpiece surface.

--Key Advantages:

Unmatched Consistency: Eliminates human error, ensuring every part meets the same strict quality standards.

Superior Efficiency: Enables 24/7 operation, drastically shortening production cycles compared to manual labor.

High Process Flexibility: Allows for quick changeovers between different part models by simply loading a new program, ideal for high-mix production environments.

Enhanced Safety & Traceability: Removes operators from hazardous work conditions and provides full data logging for quality control.

--Typical Application Scope:This technology is ideal for complex, high-volume precision auto parts like engine blocks, transmission housings, and NEV components. It is also essential in the communications and 3C electronics sectors for parts requiring a flawless die casting surface finish, such as filter housings and laptop bodies.

II. Abrasive Blasting Deburring

These methods use a high-velocity fluid stream carrying abrasive media to impact the workpiece surface, achieving both deburring and surface finishing.

--Abrasive/Shot Blasting:

Abrasive Blasting (Sandblasting): Uses compressed air to propel media like glass beads or aluminum oxide at high speed. It effectively removes smaller burrs and flashes while creating a uniform matte die casting surface finish.

Shot Blasting: Propels steel shot from a high-speed rotating wheel, delivering a more powerful impact and higher efficiency. It is ideal for cleaning robust die-cast parts, simultaneously performing deburring, descaling, and surface strengthening.

Advantages: Fast processing speed, capable of treating complex internal cavities, and relatively cost-effective.

--High-Pressure Water Jet Deburring:This process uses a high-pressure pump to create a "water knife" at thousands of atmospheres of pressure, which impacts the part. The energy of the water precisely removes burrs, especially on softer metals like aluminum and copper.

Advantages: No thermal stress, does not damage the part surface, cleans away chips and oil, and is particularly adept at handling burrs in cross-holes and deep holes.

III. Advanced & Special Processes

For microscopic or extremely hard-to-reach burrs, several special processes have been developed.

--Ultrasonic Deburring:Parts are placed in a liquid medium where ultrasonic waves create a cavitation effect. The implosion of tiny bubbles generates micro-shockwaves that dislodge microscopic burrs invisible to the naked eye. It is ideal for small, delicate components in fields like precision instruments and medical devices.

--Electrochemical Deburring (ECDM):Using the principle of electrolysis, a shaped tool (cathode) and the workpiece (anode) are placed in an electrolyte solution. An electrical current dissolves and removes the burr material without any physical contact.

Advantages: Extremely fast (seconds), stress-free, can perfectly process any hard-to-reach internal or cross-hole burrs with very high precision.

Conclusion

In summary, there are many diverse deburring methods available; there is no single "best" method, only the "most suitable." For modern, high-volume die casting production, automated solutions like CNC/robotic deburring and shot/abrasive blasting have become mainstream due to their advantages in cost, efficiency, and quality consistency.

This article has explored various mainstream deburring methods. However, selecting the optimal combination of tools and processes for a specific die-cast product is a deeper subject. In our next article, we will focus on tool selection and automated solutions for deburring die-cast parts. Please stay tuned!