LR-ZM6B-65 CNC Grinding Cell

Brand :Daseon

Product origin :China

Delivery time :30 Days

The Mid-Scale Deburring System by DASEON is the definitive solution for manufacturers seeking precision, flexibility and scalability. With SYNTEC’s advanced 6-axis control, rapid tooling adaptability, and compliance with global standards, this system streamlines workflows while maintaining rigorous quality benchmarks. From automotive transmissions to aerospace brackets, the LR-ZM6B-65 empowers industries to achieve higher throughput, lower operational costs, and consistent micron-level accuracy.

In the dynamic landscape of modern manufacturing, the LR - ZM6B - 65 Mid - Scale Deburring System emerges as a key player in Industrial Automation, offering unparalleled Precision Machining for medium - sized components. This system is engineered to meet the rigorous demands of various industries, including Automotive Deburring, while incorporating Energy - Efficient Grinding principles to enhance sustainability and productivity.

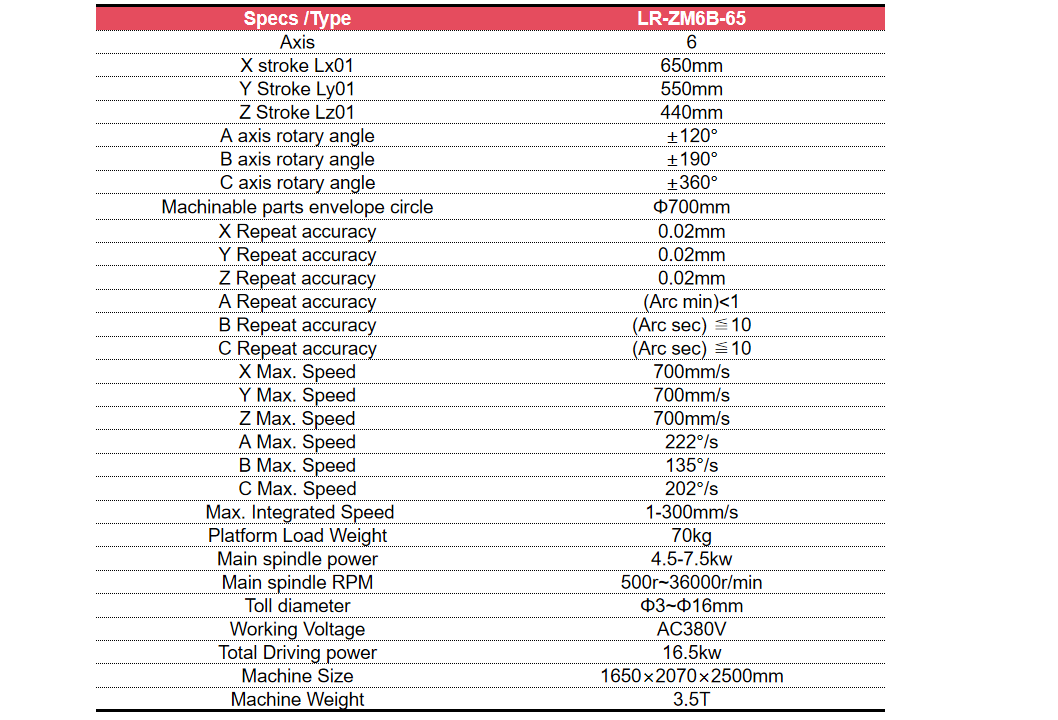

Core Technical Specifications

1. Precision Machining Capabilities

The LR - ZM6B - 65 Mid - Scale Deburring System is built upon advanced Precision Machining technologies.

Axis Configuration: X/Y/Z linear axes (650mm/550mm/440mm strokes) + A/B/C rotary axes (±120°/±190°/±360°), enabling precise handling of complex geometries.

Repeat Accuracy: ≤0.02mm (X/Y/Z), ≤10 arc seconds (B/C axes), ensuring high - quality results in Precision Machining tasks.

Spindle Power: 4.5–7.5kW, 500–36,000 RPM, providing the necessary force for effective deburring while maintaining precision.

2. Industrial Automation Integration

Integrated with Industrial Automation, the system boosts operational efficiency.

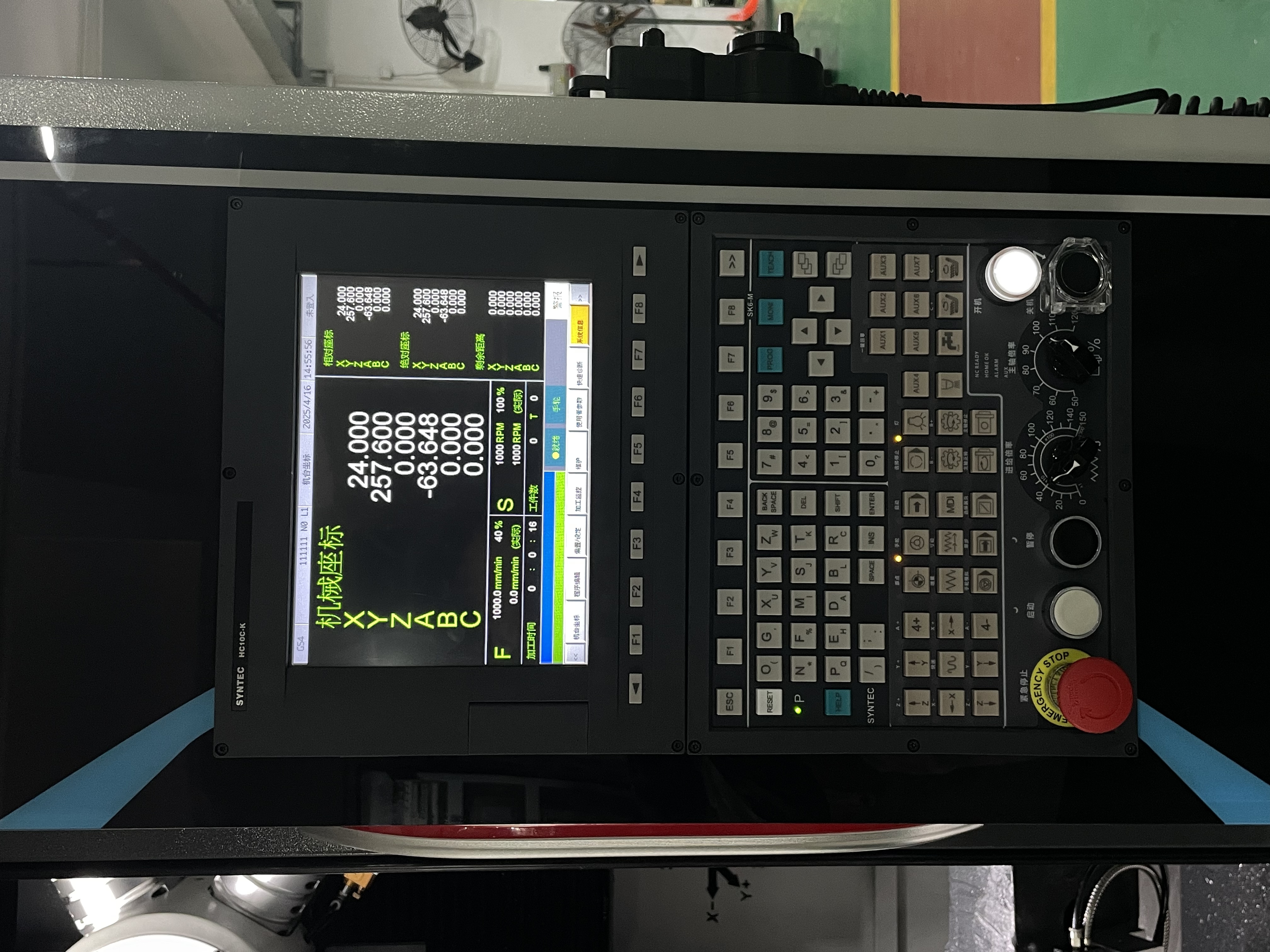

SYNTEC Control System: Features advanced algorithms for 6 - axis linkage, enabling complex 3D trajectories. This Industrial Automation - driven control ensures seamless operation and reduces human error.

Max. Speed: 700mm/s (linear axes), 222°/s (A - axis), achieving high - speed processing without compromising accuracy, a hallmark of Industrial Automation in manufacturing.

3. Advanced Tooling for Automotive Deburring

For Automotive Deburring, the system offers specialized solutions.

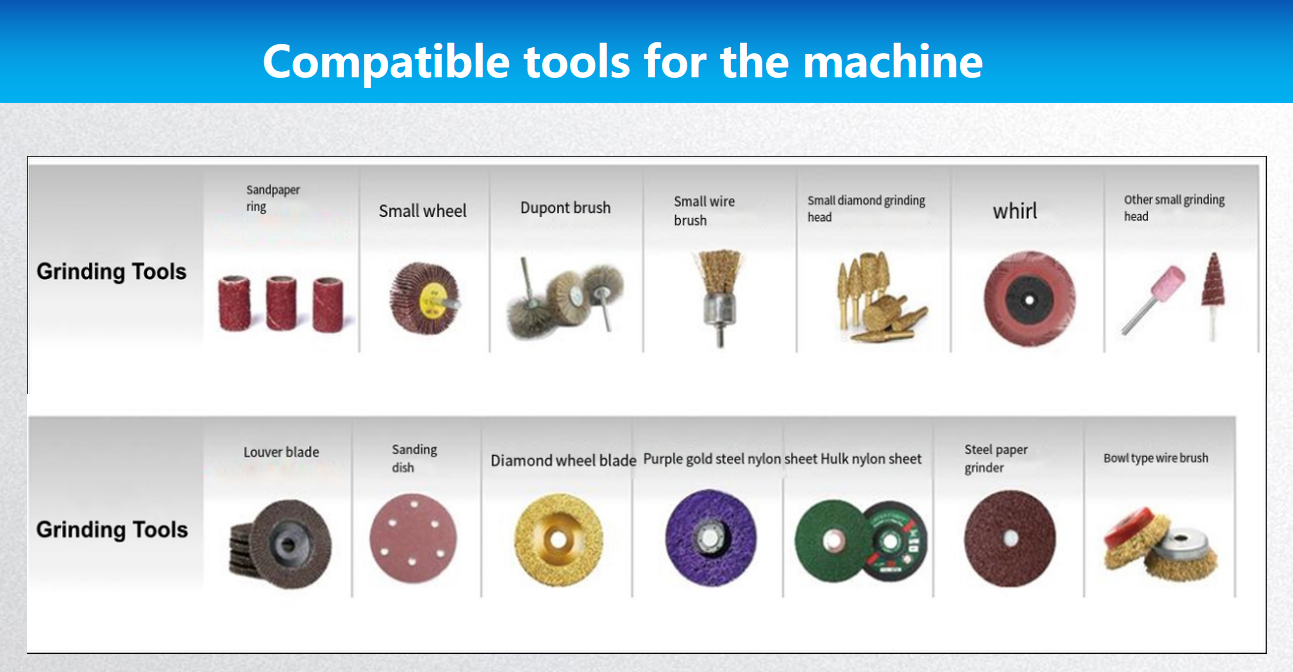

6 - Station Rotary Tool Changer: Swaps rigid tools (milling cutters, reamers) and flexible tools (steel brushes, grinding wheels) in <3 seconds, optimizing Automotive Deburring processes.

Tool Breakage Detection: Halts operations within 0.2s to prevent defective parts, crucial for maintaining quality in Automotive Deburring.

4. Energy - Efficient Grinding Features

Incorporating Energy - Efficient Grinding, the system reduces operational costs.

Automatic Tool Compensation: Laser calibration adjusts for wear, extending tool lifespan and minimizing energy waste, an aspect of Energy - Efficient Grinding.

Power Management: Optimized spindle power (4.5–7.5kW) ensures energy - efficient operation, aligning with Energy - Efficient Grinding principles.

Industry - Specific Applications

1.Automotive Manufacturing

The LR - ZM6B - 65 Mid - Scale Deburring System is ideal for Automotive Deburring.

Transmission Housings: Deburrs gearbox castings using Precision Machining, ensuring leak - proof seals for lubricant systems.

EV Charging Ports: It processes aluminum housings with ≤0.03mm tolerances through Industrial - Automation - assisted Precision Machining.

2.General Industrial Applications

Beyond automotive, the system serves various industries with its Precision Machining and Industrial Automation.

Aerospace Components: Cleans deep cavities (≥150mm) in steel hydraulic manifolds, complying with strict standards.

Consumer Durables: Polishes internal channels of industrial pump housings to eliminate flow restrictions, using Precision Machining capabilities.

Energy - Efficient Grinding and Safety

The LR - ZM6B - 65 Mid - Scale Deburring System emphasizes Energy - Efficient Grinding and safety.

IP54 Enclosure: Fully enclosed design with safety light curtains and emergency stops, ensuring operator safety.

Energy Optimization: Reduces idle consumption, aligning with Energy - Efficient Grinding goals and sustainable manufacturing practices.

Parameter

Conclusion

The LR - ZM6B - 65 Mid - Scale Deburring System is a comprehensive solution that combines Precision Machining, Industrial Automation, Automotive Deburring expertise, and Energy - Efficient Grinding features. It caters to the diverse needs of modern manufacturing, ensuring high - quality results, operational efficiency, and energy savings. Invest in this Mid - Scale Deburring System to elevate your production processes and stay ahead in the competitive manufacturing landscape.