- Home

- >

- News

- >

- Technical Insights

- >

- Aluminum Degassing Explained: The Science Behind Removing Hydrogen and Inclusions

Aluminum Degassing Explained: The Science Behind Removing Hydrogen and Inclusions

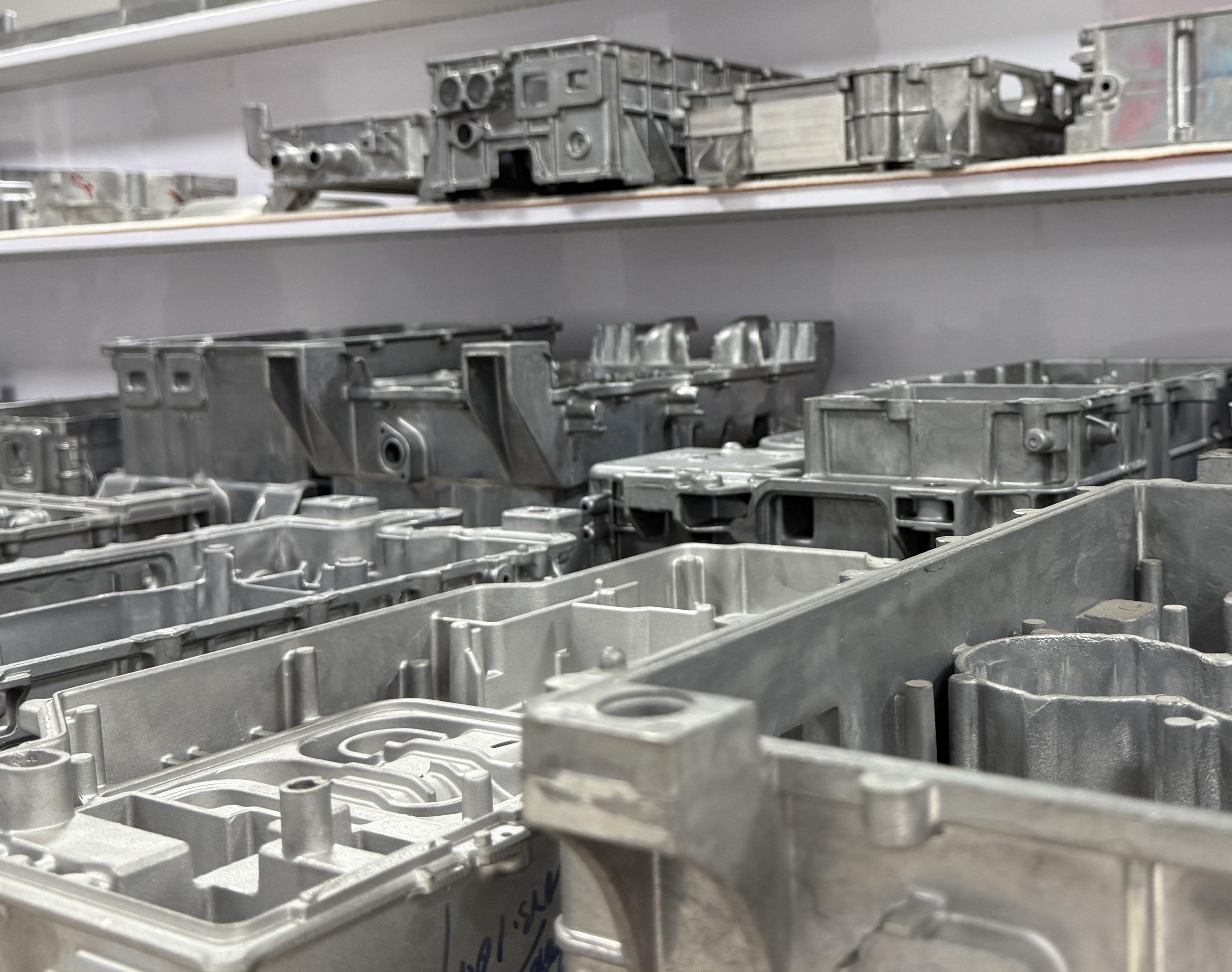

In precision die casting, effective Die Casting Quality Control begins with a pure, stable melt. Gas porosity and oxide inclusions are primary defects that compromise a part's density and mechanical properties. This guide provides an in-depth analysis of the source of gas in aluminum alloys and the core principles of the Aluminum Degassing process, the foundational step in quality production.

I. The Source of the Problem: Unveiling the "Gas" in Aluminum Alloys

1. Hydrogen is the Sole CulpritOver 85% of the gas dissolved in molten aluminum is hydrogen, primarily originating from the reaction with water vapor (H₂O) in the environment. Therefore, in die casting, "gas content" is effectively synonymous with "hydrogen content."

2. The Drastic Drop in SolubilityHydrogen's danger comes from its drastic drop in solubility as aluminum cools. Its solubility plummets from approx. 0.68 mL/100g in the liquid state to just 0.036 mL/100g in the solid state. During the rapid solidification of die casting, this excess hydrogen gets trapped and precipitates, forming Hydrogen Porosity defects (pinholes).

II. The Synergistic Threat: Oxide Inclusions and Hydrogen

Beyond hydrogen, another major source of defects is Oxide Inclusions in Aluminum, primarily alumina (Al₂O₃). Worse, these two defects work in synergy: the rough, porous oxide films act like sponges, trapping more moisture and hydrogen, which in turn increases the gas content of the melt. A comprehensive Molten Metal Treatment strategy must therefore be capable of removing both hydrogen and oxide inclusions.

III. The Core Principle of the Degassing Process

Modern Aluminum Degassing is a crucial form of Molten Metal Treatment that operates on physicochemical principles, by introducing an inert gas (usually argon or nitrogen) into the melt.

1. The Law of Partial PressuresBased on this physical law, hydrogen atoms naturally diffuse from an area of high partial pressure (the melt) to an area of zero partial pressure (the inert gas bubbles). As the bubbles rise, they continuously carry the hydrogen away from the molten metal.

2. The Flotation EffectAs the inert gas bubbles ascend, they physically collide with and attach to solid Oxide Inclusions in Aluminum. These inclusions are then carried to the surface by the buoyant force of the bubbles, where they can be skimmed off as dross.

Conclusion

In summary, controlling melt quality is a battle against hydrogen and oxides. A successful Aluminum Degassing process efficiently combines chemical hydrogen removal with physical inclusion removal, forming the most critical first step in Die Casting Quality Control.

This article has explored the core principles of degassing. In future updates, we will continue to analyze other key processes during smelting. Please stay tuned.