- Home

- >

- News

- >

- Technical Insights

- >

- An Analysis of Cracking in Die Castings: Causes, Classification, and Prevention

An Analysis of Cracking in Die Castings: Causes, Classification, and Prevention

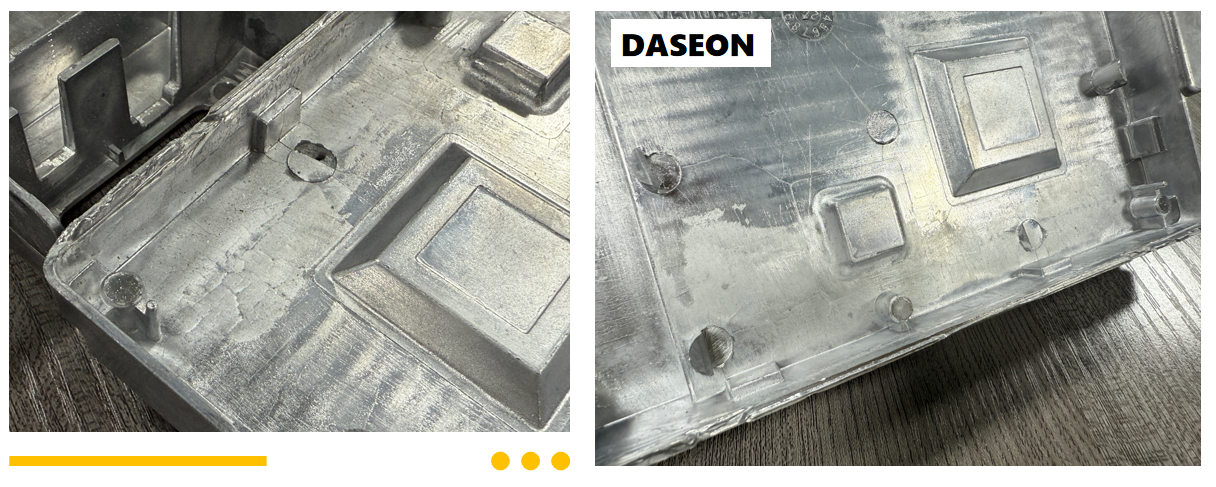

Cracking is a critical structural defect in die-cast components that directly compromises product integrity and service life. Effective prevention requires a deep understanding of the failure mechanism. This article shares core technical insights into die-casting cracks to help industry professionals identify and solve the problem at its root.

1. Classification of Cracks: Hot Tears vs. Cold Cracks

First, it is crucial to distinguish between two fundamentally different types of cracks, as their characteristics point directly to their cause:

Hot Tears (Hot Cracking): Occur at high temperatures during the final stages of solidification, caused by hindered shrinkage. The key identifier is an oxidized, dark grey fracture surface. The crack path is typically irregular and follows the grain boundaries (intergranular). This is the most common type of cracking found in die casting.

Cold Cracks: Form after the casting has cooled to lower temperatures. They are primarily caused by mechanical stresses during ejection or by high residual stress. The fracture surface is unoxidized, showing a bright metallic luster. The crack is often straight and may propagate through the grains themselves (transgranular).

2. Core Causes of Cracking

The formation of cracks is a result of the interplay between material, tooling, and process factors.

Metallurgical Factors:

——Alloy Composition: An alloy with a wide solidification range, harmful impurities (e.g., high iron content), or an improper ratio of key elements (e.g., silicon in Al-Si alloys) will have a higher propensity for hot tearing.

——Melting Process: Overheating the melt or holding it for too long can lead to a coarse grain structure, reducing the alloy's strength and ductility at high temperatures.

Tooling and Part Design Factors:

——Poor Structural Design: Abrupt changes in wall thickness and sharp internal corners with insufficient fillet radii are major sources of stress concentration, making these areas prone to cracking.

——Unbalanced Mold Temperature: Localized overheating in the die creates "hot spots." These areas solidify last and are pulled apart by the surrounding solidified sections, leading to tears.

——Ejection System: Insufficient draft angles or an uneven distribution of ejector pins can exert non-uniform mechanical stress on the part during ejection, causing cold cracks.

3. Systematic Prevention Strategies

A systematic approach is required to prevent cracking:

Optimize Design: Ensure uniform wall thickness in the part design and use generous fillet radii at all transitions.

Control Materials: Select alloys with low hot-tearing susceptibility and strictly manage the melting process to ensure proper composition and a fine grain structure.

Refine the Process: Optimize the mold's thermal balance to avoid hot spots. Set appropriate holding times and die-opening sequences to ensure the casting has sufficient strength before ejection.

Perfect the Tooling: Design a balanced and stable ejection system that ensures smooth, uniform part release.

In summary, controlling cracks is a systematic effort that spans part design, material science, mold engineering, and process control. Only by managing each of these stages with precision can crack defects be fundamentally eliminated.