- Home

- >

- News

- >

- die casting manufacturing

- >

- Choosing the Right Casting Process: A Comparison of High-Pressure, Low-Pressure, and Gravity Die Casting

Choosing the Right Casting Process: A Comparison of High-Pressure, Low-Pressure, and Gravity Die Casting

I. High-Pressure Die Casting (HPDC): The Most Widespread and Efficient Core Process

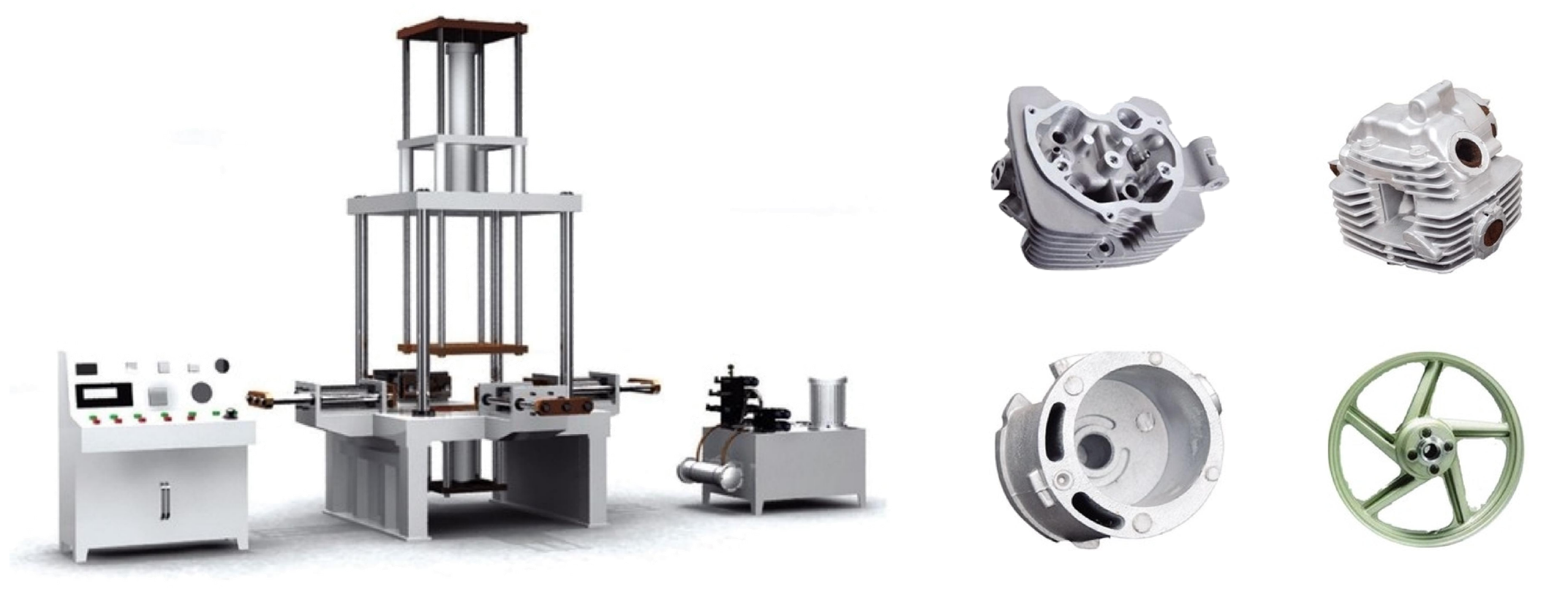

High-pressure die casting is currently the most prevalent and efficient process in the die casting field. It involves injecting molten metal into a mold cavity at high speed and under high pressure. Based on the injection mechanism, it is primarily divided into two categories: hot-chamber and cold-chamber.

Hot-Chamber Die Casting: The injection mechanism is immersed directly in the molten metal, making it suitable for low-melting-point alloys (e.g., zinc, magnesium). Its advantages include fast cycle speeds (up to 15+ cycles per minute) and ease of automation. However, its clamping force is limited (typically ≤400 tons), making it difficult to produce large parts.

Cold-Chamber Die Casting: Molten metal is ladled into the shot chamber "before each shot" and is not in continuous contact with the injection mechanism. This makes it suitable for high-melting-point alloys (e.g., aluminum, copper). Its advantages include the ability to withstand much higher injection pressures (1,500–25,000 psi), enabling the production of complex, thin-walled components. However, its cycle time is slightly longer than the hot-chamber process.

HPDC can efficiently produce parts with complex shapes, high strength, and excellent surface finishes, and is widely used in fields such as automotive pump bodies, valve components, and consumer electronics housings.

II. Low-Pressure and Gravity Die Casting: Supplementary "Non-High-Pressure" Processes for Specific Needs

In addition to HPDC, low-pressure and gravity die casting serve as complementary processes for specific scenarios such as large complex parts and low-cost / small-batch production:

Low-Pressure Die Casting (LPDC): Molten metal is pushed into the mold at a low pressure (from a few to several tens of bars), resulting in a smoother filling process. The advantage is a significant reduction in gas and shrinkage porosity, leading to denser castings. It is ideal for products requiring high airtightness, such as automotive wheels and engine blocks, balancing both quality and cost by reducing equipment pressure requirements.

Gravity Die Casting: Relies on gravity to naturally fill the mold. Its advantages are low equipment costs and process flexibility, making it suitable for small batches or large, irregularly shaped castings (like machine tool beds and large valves). While its production efficiency is lower than HPDC, it can meet custom or non-mass-production needs at a lower cost. It is also well-suited for parts with thicker walls and less complex internal structures, such as brake calipers and pistons.

III. Special Processes: Advanced Technologies for Eliminating Defects and Enhancing Performance

As industry demands for high-performance, high-density castings have grown, special processes like vacuum and squeeze casting have been developed, primarily to solve common casting defects like gas and shrinkage porosity:

Vacuum Die Casting: Air is evacuated from the mold cavity before injection, dramatically reducing the gas porosity in the casting and improving its density and mechanical properties. It is ideal for components with extremely high requirements for airtightness and strength (such as aerospace structural parts and automotive engine cylinder heads) and has a production efficiency similar to conventional die casting, making it easy to industrialize.

Squeeze Casting: This process merges the features of "casting" and "forging." High pressure is applied during metal solidification, completely eliminating shrinkage porosity and resulting in castings with properties close to forgings (e.g., strength, density). It is often used for high-strength structural parts in high-end equipment (such as automotive chassis components and critical aerospace parts).

A deep understanding of the characteristics and boundaries of these processes is our core competency as an equipment manufacturer. At DASEON, we provide comprehensive casting solutions, from efficient hot-chamber and cold-chamber die casting machines to low-pressure and gravity casting equipment suitable for high-quality components. We are dedicated to matching each customer with the manufacturing process that best enhances their product's value, helping them to excel in a competitive market.