- Home

- >

- News

- >

- die casting manufacturing

- >

- Defect Analysis: Understanding and Controlling Flashing in Die Casting

Defect Analysis: Understanding and Controlling Flashing in Die Casting

In the field of precision manufacturing, every detail of a die-cast component is critical. Among these, "flashing" (also known as burrs or fins) is one of the most common defects in die casting production. Its presence not only impacts a product's aesthetics but can also lead to functional failure and increase post-processing costs. This article provides an in-depth look at the definition and causes of flashing, along with a series of effective strategies for its prevention and control, aimed at helping companies enhance product quality.

What is Die Casting Flashing?

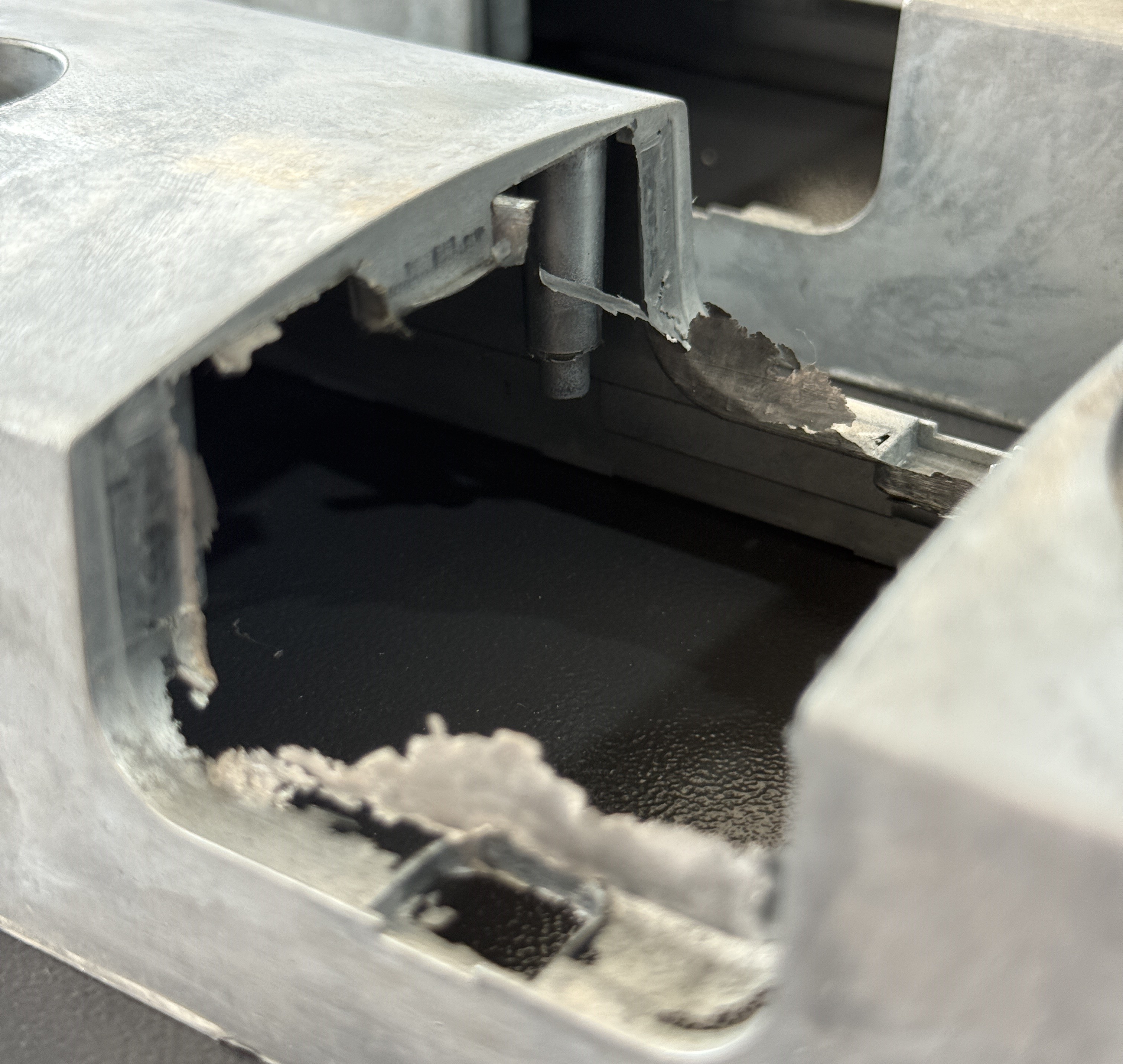

Flashing refers to excess molten metal that leaks from the mold's parting line, inserts, or slider gaps during the die casting process, solidifying into a thin, sharp metal film. Although typically only 0.1mm to 0.3mm thick, flashing can compromise the dimensional accuracy and fit of a die-cast part, and may even damage the mold, impacting the internal integrity of the product.

Analysis of Flashing Causes

Flashing is not a random occurrence; it is typically the result of a combination of factors related to equipment, mold, and process.

1. Equipment and Process-Related Causes:

Insufficient Clamping Force: The die casting machine's clamping force is improperly set or too low to counteract the high-pressure injection force, causing the mold's parting line to open up.

Excessive Injection Speed: The injection speed or pressure peak is too high, causing the molten metal to impact the mold at an excessive velocity, which exacerbates the stress on the clamping force.

Platen Misalignment: The parallelism between the moving and stationary platens is out of tolerance, preventing a tight seal when the mold is closed.

2. Mold-Related Causes:

Mold Wear: Gaps in the mold's fit, such as between guide pins, bushings, or sliders, have widened due to wear, providing an escape route for molten metal.

Insufficient Mold Rigidity: The mold's structural design is inadequate, lacking the rigidity to withstand deformation under the high-pressure shot.

Uneven Parting Surface: The mold's parting surface is either not thoroughly cleaned or has become uneven from long-term use, compromising the mold's ability to seal tightly.

Prevention and Control: A Comprehensive Approach

To fundamentally solve the flashing problem, a systematic solution is required, covering hardware, mold design, and the post-processing stage.

Hardware Assurance: Selecting a die casting machine with superior performance is the first step. Modern die casting machines feature higher clamping precision, a more stable injection system, and stronger clamping force, which reduces the likelihood of flashing at the source.

Mold Optimization: Ensure the mold has sufficient rigidity. The mold design should properly account for overflow vents and runners. Regular mold maintenance and cleaning of parting surfaces are also crucial to guarantee a smooth and tight seal.

Parameter Adjustment: By optimizing injection speed, pressure, and temperature, the molten metal can flow smoothly within the mold cavity. This reduces impact on the mold and lowers the risk of overflow.

Automated Post-Processing: Even with optimized processes to minimize flashing, the post-processing stage remains indispensable. Efficient deburring and polishing tools, such as Daseon's automated machine, can precisely remove tiny flashes, ensuring the consistency of die casting quality, while significantly boosting production efficiency and controlling costs.

By combining high-quality equipment, rigorous process control, and intelligent post-processing tools, die casting companies can significantly reduce or even eliminate flashing defects, ultimately achieving their goals for efficiency and quality.