- Home

- >

- News

- >

- Company News

- >

- Die Casting Automation: Building the Core "Island" of a Lights-Out Cell

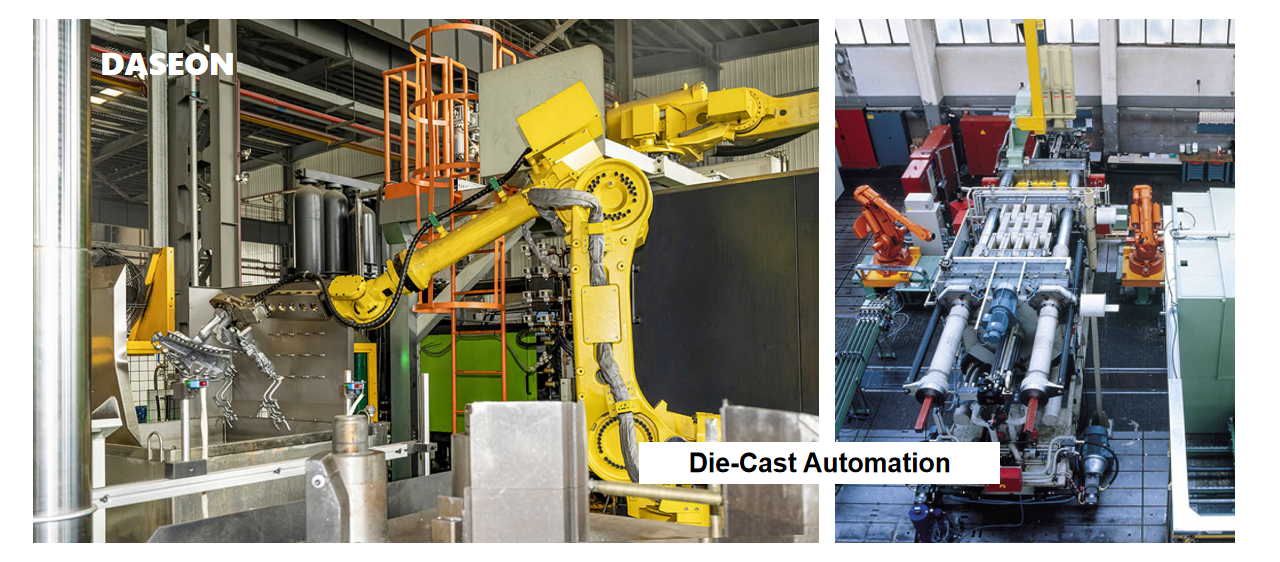

Die Casting Automation: Building the Core "Island" of a Lights-Out Cell

The traditional die casting shop is facing an existential challenge from a global Die Casting Labor Shortage, rising costs, and strict quality demands. The solution is the "Lights-Out" cell—a complete, data-driven automation system. This first article in our series provides a panoramic view of the "heart" of this automation cycle: the Core Die Casting Island and its synergistic equipment.

Part I: The Core Die Casting Island — The Heart of the Automation Cycle

The "Core Die Casting Island" is the fastest-paced and most complex hub in the entire automated cell. It operates with the die casting machine as its "brain," directing all peripheral equipment in a high-speed, closed-loop cycle to transform molten metal into a formed part.

In DASEON's full-chain solution, this heart is composed of several key components working in concert to solve real-world challenges:

1. The [DASEON] Die Casting Machine: The Central Hub and Brain

The die casting machine is the command center for all action. In an era where customers demand 100% quality traceability, its advanced PLC control system is not just a coordinator, but a "black box." It precisely orchestrins the timing of every peripheral device while recording the speed, pressure, and time curves of every single shot, providing the critical data needed to solve process problems and satisfy customer audits.

2. The [DASEON] Automatic Ladling Machine: The First Line of Defense Against Human Error

Industry Pain Point: Manual ladling is a primary source of process instability. Operator fatigue and estimation errors lead to shot-to-shot weight fluctuations (±5% or more), which directly cause flash, short fills, or shrinkage.

DASEON Solution: The servo-driven Automatic Ladling Machine completely eliminates this "human variable." It delivers a consistent shot weight with high precision (e.g., within ±1.5%), which is the fundamental prerequisite for a stable process and lower scrap rates.

Case Data: In a recent automotive project, one of our clients reduced their scrap rate attributable to inconsistent shot size by 3-4 percentage points just by implementing our servo-ladling system.

3. The [DASEON] Hydraulic Mold Clamps: The Cornerstone of Safety and Efficiency

Industry Pain Point: The "high-mix, low-volume" order trend makes frequent mold changes the new normal. Traditional manual bolting can take hours, killing OEE (Overall Equipment Effectiveness).

DASEON Solution: Hydraulic Mold Clamps ensure the mold remains immobile under immense injection pressure, preventing flash. More importantly, they are the key to quick mold change.

Case Data: A 3C electronics client of ours, who changes molds several times a day, used our QMC system to reduce their average mold change time from 2.5 hours down to under 20 minutes. This added 2-3 hours of effective production time per machine, per day, providing a massive boost to their OEE.

4. Auto-Spraying & The [DASEON] Automatic Extractor: Escaping the High-Heat, High-Risk Zone

Industry Pain Point: Spraying and extraction from a hot mold is the most dangerous and labor-intensive job in the shop. It is the epicenter of the die casting labor shortage problem.

DASEON Solution: An auto-spray robot and an Automatic Extractor perfectly replace this high-risk role. The extractor, an essential tool for anyone asking how to reduce die casting cycle time, enters the mold, grips the hot part, and extracts it smoothly, all on a consistent, optimized timer.

Case Data: In an industrial housing project, a client's manual extraction cycle fluctuated between 45 and 60 seconds, causing severe mold temperature instability. Our servo-extractor stabilized the total cycle at a constant 42 seconds. This not only boosted output by over 10% but the stable cycle led to a stable mold temperature, which in turn dramatically improved the dimensional consistency of the castings.

Conclusion and Preview

From automated ladling, precise spraying, secure clamping, high-speed injection, to stable extraction, this "Die Casting Island" built from DASEON's core equipment forms a closed-loop system that runs at high speed without manual intervention. It uses real data to respond to the industry's four core anxieties: cost, efficiency, quality, and safety.

This, however, is only the beginning of the part's journey. The extractor has only released a "raw casting," complete with gates and burrs. In our next article, we will follow this part into the second stage of the automated cell—the downstream post-processing line—to explore how it is automatically fed into hydraulic presses, shot blasters, and polishing machines to become a finished product. Please stay tuned.