- Home

- >

- News

- >

- Technical Insights

- >

- Die Casting Mold Design: Mastering the Gating System and Injection Control

Die Casting Mold Design: Mastering the Gating System and Injection Control

In the previous two articles, we analyzed the mold's "metronome"—the cooling system—and its "breathing channel"—the venting system. We have created the ideal thermal environment for solidification and cleared the path for gas to escape.

However, the success of these preparations depends entirely on the final, most complex, and most critical element: the Gating System. It is the "precision highway" that guides molten metal into the cavity, and its design dictates the success of the filling process and the final quality of the casting.

Part III: The Gating System — The "Precision Highway" for Molten Metal

The gating system refers to the entire network of channels that molten metal flows through, from the machine's shot sleeve to the part cavity. Its core objective is to fill the cavity completely in the shortest possible time, in a stable, orderly, and controlled manner, while avoiding defects like turbulence, gas entrapment, mold erosion, and premature solidification.

1. Key Design Considerations

--Runner System Design:The runner is the main artery connecting the shot sleeve to the in-gates. Its design is guided by the principle of "minimizing pressure and heat loss." A well-designed runner typically uses a trapezoidal cross-section for a better surface-area-to-volume ratio, incorporates smooth arc transitions at all turns to prevent turbulence, and features a gradually decreasing cross-sectional area to maintain pressure and accelerate the flow toward the gates.

--In-Gate Design:The in-gate is the final valve before the metal enters the cavity and is the most technically demanding part of Gating System Design.

Location: The gate location is a strategic decision that determines the entire fill pattern. It should be positioned to feed the thickest sections of the part first, avoid direct impingement on delicate cores, and promote a single, continuous flow front that pushes gas ahead of it towards the vents and overflows.

Size and Velocity: The gate's cross-sectional area is precisely calculated. It must be small enough to accelerate the metal to a very high velocity (30-60 m/s) but large enough to avoid premature freezing or excessive shear. Gate velocity is the core calculated parameter in Gating System Design.

--The Role of Simulation:For complex parts, perfecting a Gating System Design through experience alone is unreliable. Modern, high-end Die Casting Mold Design universally relies on CAE simulation. Mold Flow Analysis software (like MAGMASOFT or FLOW-3D) allows designers to visualize the filling process, temperature changes, and potential defects, enabling them to optimize the gating system digitally before cutting steel.

2. The Synergy Between Mold Design and Die Casting Machine Performance

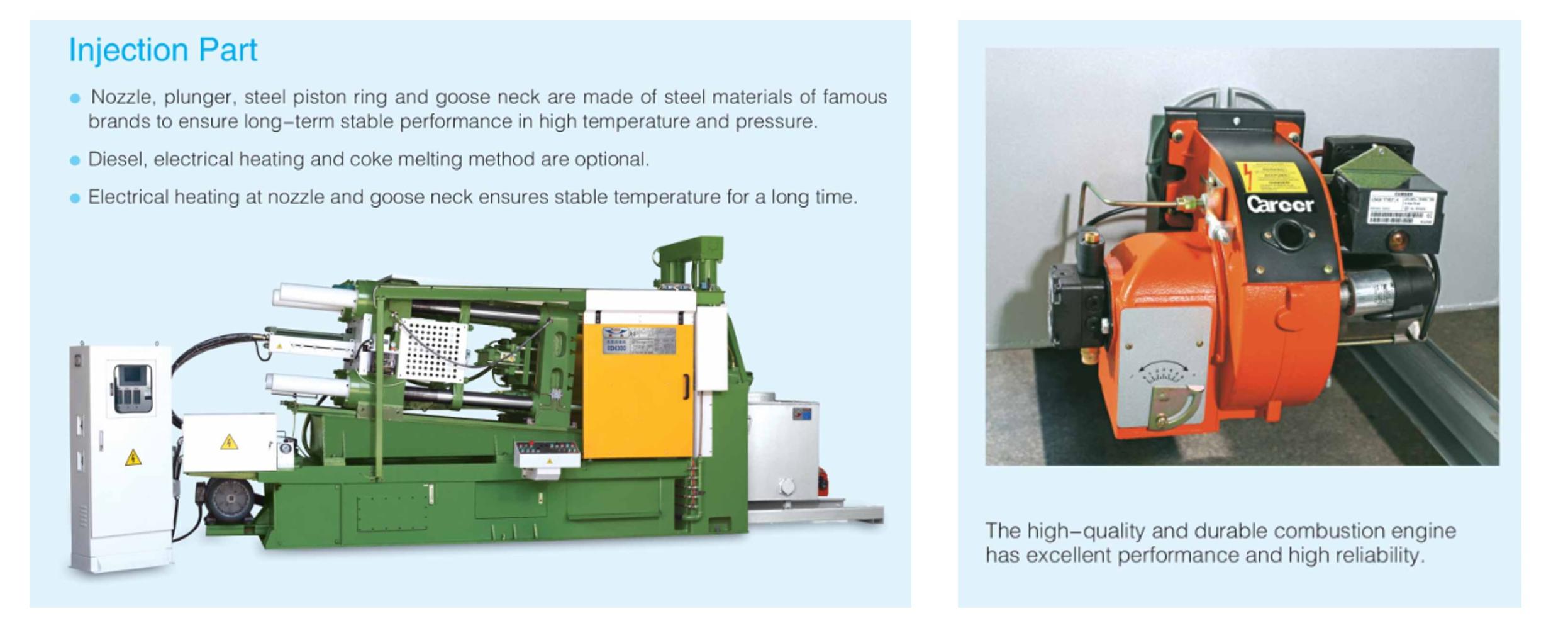

A perfectly designed gating system is only a static blueprint. Bringing that blueprint to life depends entirely on the dynamic performance of the Die Casting Machine. An excellent mold must be paired with an excellent machine.

--The Core Synergy: Precise Replication of Injection Performance

The entire gating system is mathematically designed to function with a specific filling speed and pressure profile. A brilliant mold will fail if the Die Casting Machine cannot deliver this profile with precision and repeatability. The machine's Injection Control system is the engine that drives the mold.DASEON's die casting machines are equipped with advanced, real-time closed-loop Injection Control systems. This technology ensures that the actual injection curve of every shot perfectly matches the set target curve. This high-repeatability precision guarantees that the calculated gate velocity is achieved, minimizing turbulence and ensuring consistent part quality, which is the cornerstone of high-volume, high-quality production.

--The Die Casting Machine as a Diagnostic Tool

Furthermore, DASEON's intelligent control system provides real-time monitoring and display of the complete injection curve. An experienced process engineer can analyze the subtle variations in this curve (e.g., pressure peak timing, velocity switch points) to diagnose potential problems in the gating system, such as a gate freezing off prematurely or a runner obstruction. This transforms the Die Casting Machine from a simple press into an intelligent partner for process optimization.

Series Conclusion

Through this three-part series exploring the lifelines of cooling, venting, and gating, it is clear that they are not isolated systems but an interconnected, unified whole. A successful mold is the product of scientific principles, rich engineering experience, and modern digital tools like Mold Flow Analysis.

More importantly, we must recognize the inseparable synergy between the mold and the machine. Only by pairing expert Die Casting Mold Design with an advanced Die Casting Machine that features high-precision Injection Control can the full potential of the design be realized. This combination is the true foundation of modern, high-quality die casting.