- Home

- >

- News

- >

- Company News

- >

- How to automate die casting post-processing: A Full-Chain Solution Guide

How to automate die casting post-processing: A Full-Chain Solution Guide

In our last article, we forged a "raw casting" at the "Core Die Casting Island." But as any senior die casting professional knows, the post-processing shop is where a part's quality is often lost and its costs inflate. This traditional manual work—dirty, loud, and dangerous—is a notorious Die Casting Bottleneck and a black hole for Die Casting Quality Control.

This article will answer the critical question: How to automate die casting post-processing?

Part II: The Downstream Line — The DASEON Full-Chain Advantage

A modern post-processing line is an intelligent system of robots, conveyors, and specialized automated machines. At DASEON, we don't see these as isolated devices; we see them as a continuous, automated "process flow"—a core part of our Full-Chain Die Casting Solution.

1. Station 1: Automated Trimming (Removing the Gating System)

The Reality: Traditional manual trimming with saws or presses is not only slow but extremely dangerous. More importantly, it's a "breakpoint"—the die casting machine is producing at high speed, while parts pile up waiting for post-processing.

The DASEON Solution: We integrate a [DASEON] High-Speed Hydraulic Press directly into the automated line. The casting is picked from the cooling conveyor by a robot, precisely located in a trim die, and in a single stroke, the press cleanly shears all gates, overflows, and heavy flash.

The Real-Value: For an automotive structural part customer, this cell did more than just save three workers per shift. More importantly, its cycle synchronized perfectly with the die casting machine's 45-second cycle. This eliminated a critical Die Casting Bottleneck and achieved true "One-Piece Flow," where one part is cast and one part is trimmed, with no work-in-process buildup.

2. Station 2: Automated Finishing (Deburring & Polishing)

The Reality: After trimming, the fine parting-line burrs or internal cross-hole burrs are a nightmare for manual grinding. This is where Die Casting Quality Control fails. "Feel" is not a measurable standard; quality is inconsistent and depends on the worker's experience and mood.

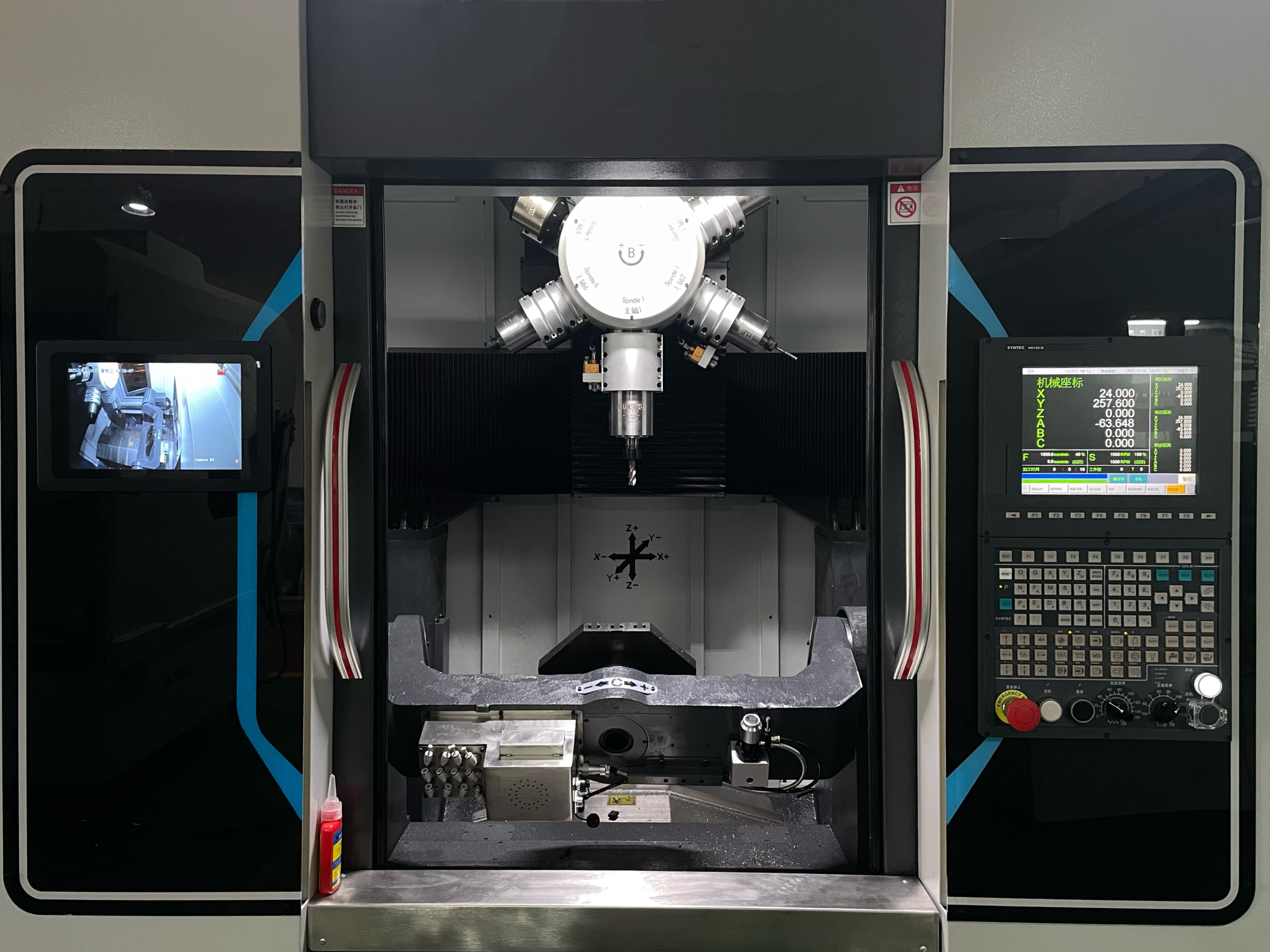

The DASEON Solution: We replace "feel" with data and programming. The part is transferred to a [DASEON] CNC Deburring Machine or Robotic Polishing Cell. Equipped with force-control systems, the robot guides a precise brush or milling tool over every edge with consistent pressure and an exact path.

The Real-Value: In a high-end faucet project, the client's manual polishing yield for A-grade surfaces struggled at 60-70%. DASEON's robotic polishing cell, with its stable force control, elevated the First Time Yield to over 95%. This is how you guarantee a perfect Die Casting Surface Finish, ensuring high process consistency and predictability.

3. Station 3: Automated Surface Strengthening & Cleaning

The Reality: Many castings, especially structural ones, don't just need to look good; they need to be durable. They require the removal of internal casting stress and a clean, prepared surface for painting.

The DASEON Solution: The part automatically moves from the deburring station into a [DASEON] Shot Blasting Machine. We match the machine type to the part: Tumble Belt (for small, non-fragile parts), Mesh Belt (for thin or flat parts needing stable transport), or Overhead Rail (for hanging large, complex parts).

The Real-Value: In a few minutes, high-velocity shot peening performs a 3-in-1 function: it removes oxides, unifies the Die Casting Surface Finish, and—most importantly—induces compressive stress (shot peening), enhancing the part's fatigue life. This replaces dirty, non-eco-friendly processes like acid pickling.

We've now mapped the framework of a "Lights-Out" cell, from the Core Island to the automated Downstream Line. This isn't just about machines; DASEON's Full-Chain Die Casting Solution delivers reliable, automated process flow as the true value.