- Home

- >

- News

- >

- die casting manufacturing

- >

- Leveraging Data and Technology to Reshape Die Casting Quality Management

Leveraging Data and Technology to Reshape Die Casting Quality Management

In the fiercely competitive landscape of automotive component manufacturing, die casting companies are facing unprecedented challenges. With the booming development of new energy vehicles, market demand is shifting from high-volume production to a multi-variety, small-batch customization model. This transition not only requires businesses to have more flexible production capabilities but also places traditional die casting quality management at the center of a "perfect storm" of core pain points.

Core Pain Points of Die Casting Quality Management

Currently, die casting companies are grappling with multiple quality management issues:

——Lag in Process Control and Defect Exposure: Traditional quality management heavily relies on manual sampling and final inspection, making it difficult to identify anomalies in real-time. Minor fluctuations in parameters like molten alloy flow and mold temperature can trigger defects such as porosity and shrinkage, which often only become apparent later, resulting in large batches of substandard products and a high scrap rate.

——Data Silos and Knowledge Gaps: Equipment data (e.g., die casting machine status), process data (e.g., injection curves), and quality data (e.g., X-ray inspection results) are fragmented and lack interconnectivity, forming "data silos." This prevents managers from conducting multi-dimensional analysis and making rapid, informed decisions. At the same time, an over-reliance on the personal experience of senior technicians means knowledge is difficult to digitize and pass on, leading to long training cycles for new hires and a high risk of knowledge loss.

——Challenges of Multi-Variety, Small-Batch Production: Facing complex parts that require high precision and airtightness, companies encounter high mold costs and frequent production process adjustments. Each product changeover necessitates recalibrating process parameters, but the lack of systematic production records increases both the production difficulty and die casting process control risks.

Daseon’s Systematic Solutions

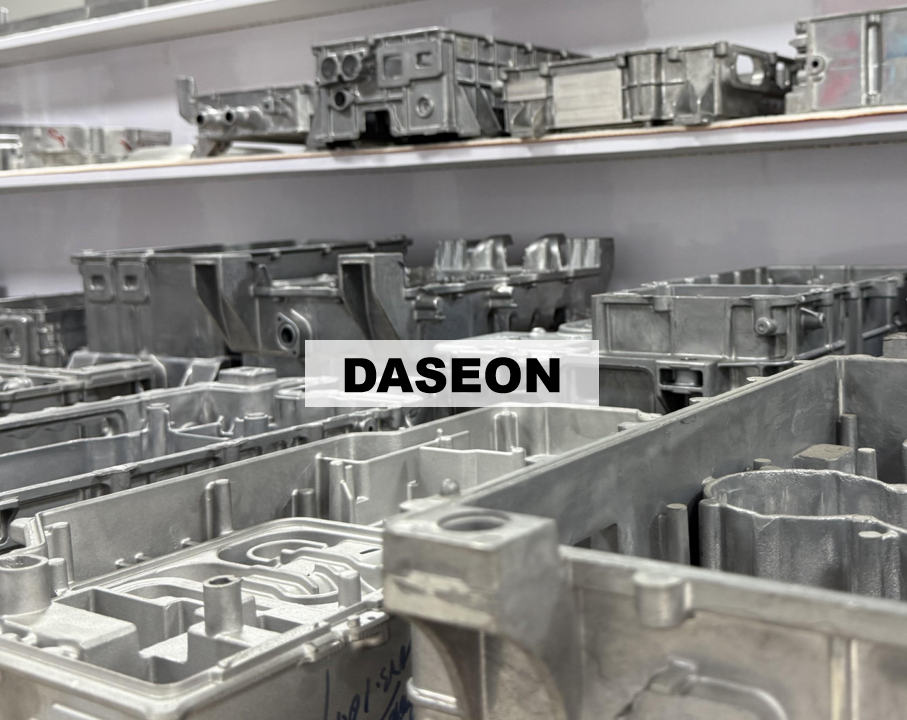

In response to these challenges, Daseon Industry is leveraging its forward-thinking strategic vision and exceptional manufacturing capabilities to provide a systematic solution for the industry, addressing the root cause of these quality management pain points.

As a pioneer in smart manufacturing, we are committed to the deep integration of technology and management to provide clients with:

——1. Data Integration for Full-Process Quality Traceability

Daseon deeply understands the importance of data connectivity. We are dedicated to the deep integration of equipment status, process parameters, and product quality data to break down data barriers. This not only enables die casting data traceability for every product but also allows for real-time monitoring of potential risks during the production process through data analysis, shifting quality control from "post-event inspection" to "proactive prevention."

——2. Automation and Intelligence to Bridge the Talent Gap

Daseon’s workshops widely utilize automated robotic production lines, which not only significantly boost production efficiency but also entrust repetitive and strenuous tasks to intelligent equipment. Our technology can transform the valuable experience of senior technicians into reproducible and executable digitalized processes, ensuring consistent and stable production. This effectively reduces the industry’s reliance on highly skilled labor and provides quality management personnel with more comprehensive technical information, allowing them to focus on higher-value die casting defect analysis and decision-making.

3. Flexible Production to Efficiently Meet Market Demands

With our comprehensive equipment system, which covers everything from die casting and post-processing to machining, Daseon is capable of efficiently meeting clients' needs for multi-variety, small-batch customization. By optimizing our production management processes, we ensure the first-time success of development and production, even with frequent product changeovers. This not only shortens product time-to-market but also effectively reduces hidden quality costs, enhancing the company’s core competitiveness in the market.

Through the deep integration of technology and management, Daseon Industry is reshaping the new landscape of die casting quality management. We are not just an equipment supplier; we are a reliable partner dedicated to collaborating with our clients to solve challenges and achieve sustainable development.