- Home

- >

- News

- >

- die casting manufacturing

- >

- Magnesium Thixomolding: The Three Key Controls for Achieving Superior Quality

Magnesium Thixomolding: The Three Key Controls for Achieving Superior Quality

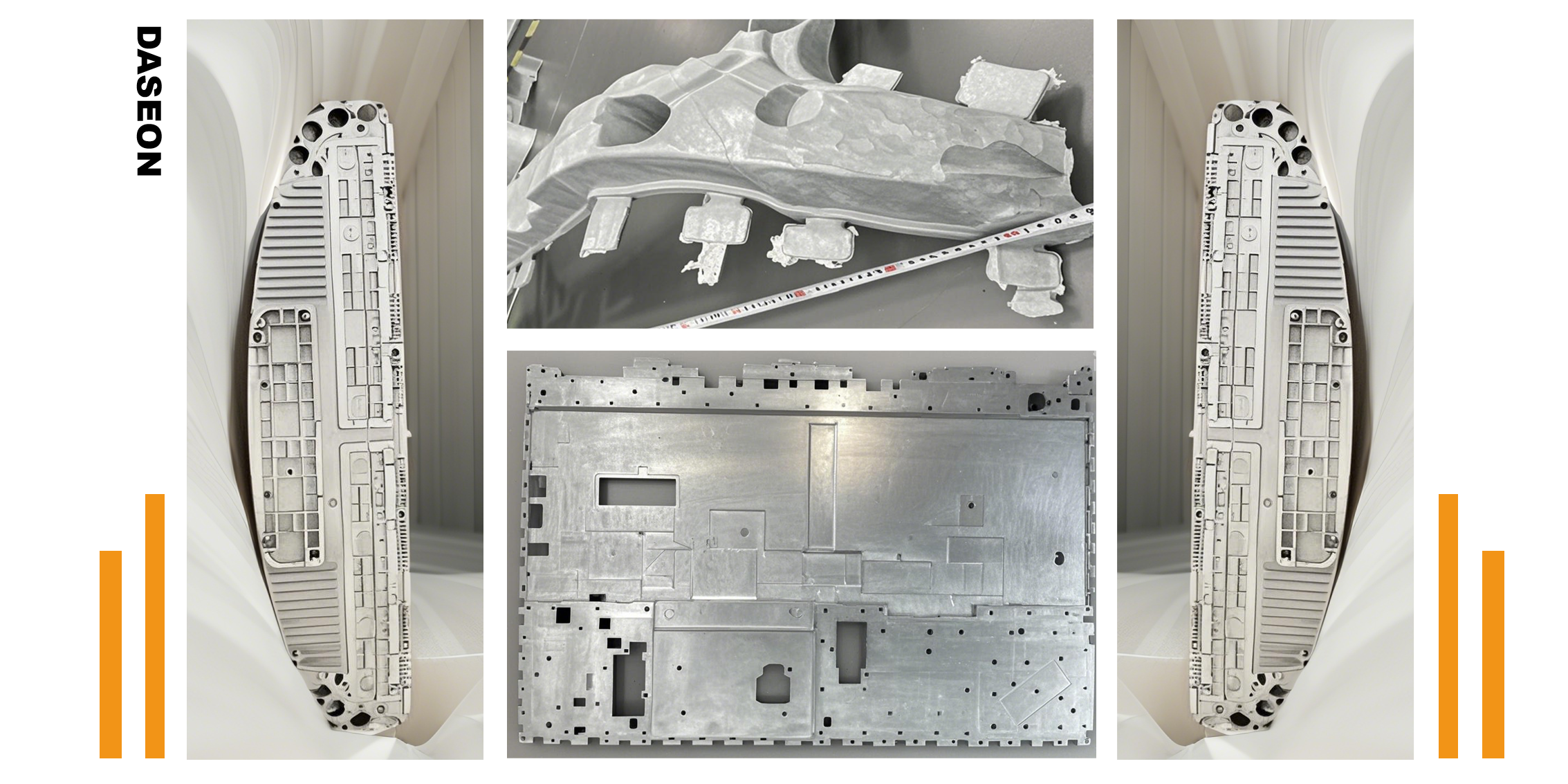

As a mature and sophisticated technology, Magnesium Thixomolding stands as a cornerstone process in precision magnesium manufacturing, valued for its inherent advantages in safety, environmental responsibility, and quality. The process fundamentally eliminates the high-temperature molten metal risks and the dependency on SF6 cover gas associated with traditional die casting. However, unlocking its full potential requires precise control over the entire process.

As experts in this field, we are sharing the three pillars of stable and successful thixomolding.

1. The Preparation and Control of a Homogeneous Slurry

The first and most critical step in thixomolding is transforming solid magnesium alloy chips into a uniform, semi-solid slurry. The quality of this slurry directly dictates the final component's microstructure and mechanical properties. The key is to employ a precision-engineered screw system that, under exact thermal regulation, heats, shears, and conveys the raw material, conditioning it into an ideal thixotropic slurry characterized by globular solid particles uniformly suspended in a liquid matrix.

2. Stable Control of the Injection Process

The viscosity and flow behavior of a semi-solid slurry are vastly different from those of a liquid metal, making the injection stage particularly critical. This demands a high-response injection system capable of real-time, closed-loop control over velocity and pressure. The objective is to achieve a stable, laminar filling pattern into the mold, which prevents defects like gas entrapment and oxidation that can result from turbulent flow, ensuring the slurry fills complex cavities completely and densely.

3. High Consistency of the Entire Process

For high-volume production, ensuring consistency from one part to the next is paramount. This requires exceptional process repeatability from the molding machine. Every stage—from material feeding and thermal management to injection—must be monitored and regulated by an integrated, intelligent control system. This ensures the long-term, stable production of high-quality parts that meet the most stringent standards.

In conclusion, mastering these three control points is the key to successfully implementing the Magnesium Thixomolding process. At [Your Company Name], our deep understanding of these process intricacies is embodied in our mature MG-Series of Magnesium Thixomolding Machines, empowering manufacturers to consistently produce superior magnesium components.