- Home

- >

- News

- >

- Industry Insights

- >

- Surface Treatment for Die Cast Aluminum: Sandblasting vs. Shot Blasting—How to Choose?

Surface Treatment for Die Cast Aluminum: Sandblasting vs. Shot Blasting—How to Choose?

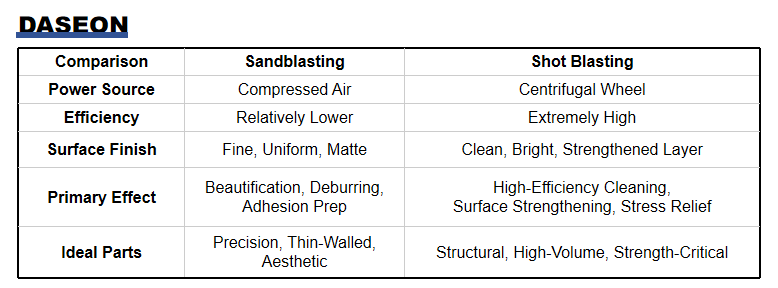

In the vast ecosystem of industrial production, surface treatment is the critical step that gives a product its "perfect coat," enhancing its quality and lifespan. For die-cast aluminum parts, sandblasting and shot blasting are like two master craftsmen; though both operate in the surface treatment field, their functions are distinctly different. Making the right choice not only affects the product's appearance but also directly impacts its mechanical properties and production costs. Today, let's unveil the mysteries of these two "masters" and explore their unique advantages and applications for die-cast aluminum.

Working Principles: The Difference in Power Source

Sandblasting: Abrasive Propelled by High-Pressure Air

The "powerhouse" of a sandblasting machine is compressed air. It uses a high-pressure air stream to propel abrasive media—such as quartz sand, glass beads, or aluminum oxide—through a specialized nozzle. This jet acts like countless microscopic chisels, finely impacting and cutting the aluminum surface. It effectively removes micro-burrs, oxide layers, and contaminants, creating a uniform matte or satin finish that provides an excellent anchor for subsequent coating or plating.

Shot Blasting: Abrasive Thrown by a High-Speed Wheel

The core of a shot blasting machine is its high-speed rotating impeller wheel. It uses centrifugal force to propel abrasive media—like steel shot, stainless steel shot, or aluminum shot—at extremely high velocity, creating a dense stream of projectiles. When die-cast aluminum parts enter the blast chamber, this powerful "storm" of media provides 360-degree coverage, performing a "bombardment-style" cleaning. It not only efficiently removes flashes, burrs, mold release agents, and oxide layers but also induces plastic deformation on the part's surface. This creates compressive stress, which strengthens the surface and significantly improves the part's fatigue resistance.

Application Scenarios: The Right Treatment for Your Aluminum Parts

When it comes to the diverse needs of die-cast aluminum, sandblasting and shot blasting each have their specialties:

When to Choose Sandblasting: For Aesthetics and PrecisionSandblasting is the "exclusive treatment" for small, precise, or appearance-critical die-cast aluminum parts.

Consumer Electronics: For products like laptop enclosures and mobile phone frames, sandblasting creates a fine, uniform matte texture that enhances the product's premium feel.

Precision Instruments & Decorative Parts: For aluminum parts with thin walls, complex features, or a high risk of deformation, the gentler impact of sandblasting can clean and beautify without damaging the structure.

High-Adhesion Requirements: Sandblasting creates a micro-roughened surface that dramatically improves paint adhesion, making it common for high-end automotive interior components and medical device casings.

When to Choose Shot Blasting: For Efficiency and Strength:Shot blasting is the "powerful backing" for high-volume, structural, or strength-critical die-cast aluminum parts.

Automotive Structural Parts: For components like engine brackets, transmission housings, and wheels, shot blasting efficiently removes surface defects and enhances durability and safety through surface strengthening.

Industrial Equipment Housings: For aluminum casings that must withstand pressure and vibration, shot blasting effectively relieves casting stresses, preventing future cracking.

High-Volume Production: Compared to sandblasting, shot blasting offers much higher levels of automation and efficiency, making it the ideal choice for reducing costs in mass production.

DASEON: Your Professional Shot Blasting Solution

Since shot blasting offers clear advantages for processing high-volume and structural die-cast aluminum parts, the next key step is selecting the right machine. At DASEON, we provide a diverse range of shot blasting solutions to meet various production needs:

Tumble Belt Shot Blasters: Ideal for batch processing of small to medium-sized aluminum parts that are not susceptible to damage from tumbling.

Overhead Rail Pass-Through Blasters: The perfect choice for large, complex, or fragile aluminum castings, such as automotive structural parts.

Mesh Belt Pass-Through Blasters : Best suited for the continuous, damage-free processing of thin-walled or flat aluminum components.

If, after reading this article, you still have questions about the selection and application of shot blasting machines or wish to explore their secrets further, we invite you to leave a message. Our team of experts is dedicated to answering your questions and providing precise, practical advice. Additionally, if you are seeking solutions for your surface treatment challenges and require high-quality post-processing technology for die-cast surfaces, feel free to contact us to discuss the possibilities. We will tailor the most suitable equipment solution to your needs and work together to create a brighter future in industrial manufacturing.