- Home

- >

- News

- >

- die casting manufacturing

- >

- Thixoforming Mold Design: A Guide to Runners, Gating, and Vacuum Systems

Thixoforming Mold Design: A Guide to Runners, Gating, and Vacuum Systems

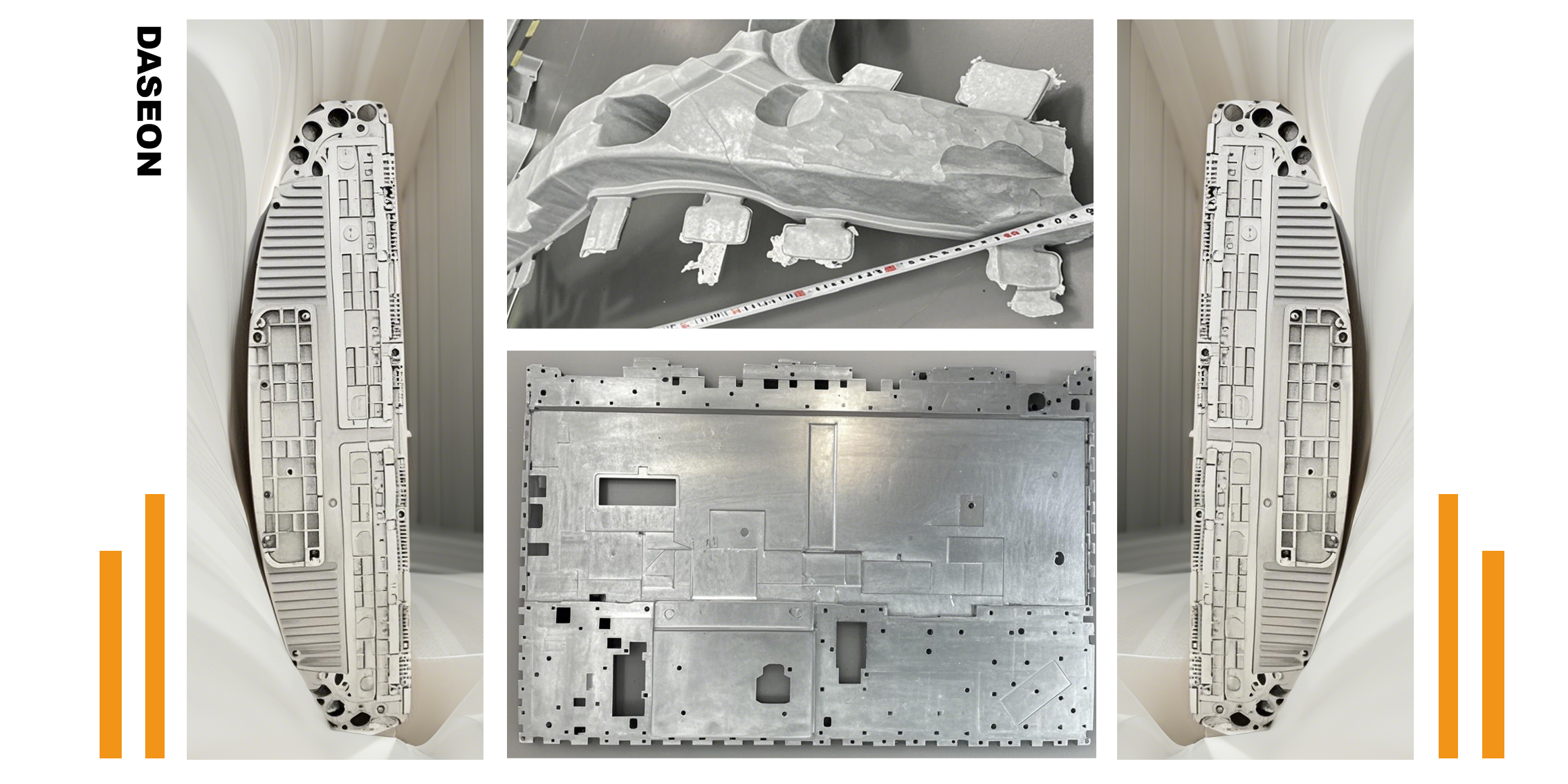

After analyzing slurry and process parameters in our series, this final article examines two equally crucial aspects: the hardware that shapes the part—the mold—and the technological backbone that enables the process—the Thixoforming Equipment. We will explore the unique requirements for Thixoforming Mold Design and the current manufacturing challenges.

I. Meticulous Craftsmanship: Mastering Thixoforming Mold Design

A successful outcome depends on a highly specialized Thixoforming Mold Design due to the slurry's unique paste-like flow.

1. Runner and Gating System: Smooth Guidance to Prevent Segregation

--Design Principle: Utilize wide, thick runners with smooth, gradual arc transitions.

--Root Cause Analysis: This is critical to reduce flow velocity and shear forces, which can cause liquid/solid segregation. The goal is to create a gentle slide for the material, not a turbulent pipe, ensuring the part’s internal structure remains uniform.

2. Venting and Overflows: Clearing the Path for a Perfect Surface

--Design Principle: Employ multi-level venting and Vacuum Assisted Die Casting (vacuum level ≤ 50 mbar), along with large overflow channels.

--Root Cause Analysis: The slurry's high viscosity makes air difficult to evacuate. Vacuum Assisted Die Casting is therefore often a necessity for high part density. Large overflow channels are also crucial to trap gas and the cooler, oxidized front of the slurry flow.

II. Challenges and Breakthroughs: The Frontier of Thixoforming Equipment

The demanding nature of Thixoforming presents several challenges for equipment design.

1. The Ultimate in Control: Precision and Response

--Challenge: The process requires a temperature control accuracy within ±5°C and dynamic injection control.

--Breakthrough: This need for precision has driven the development of high-response Servo Control Die Casting systems, which have become a standard feature on modern Thixoforming Equipment.

2. The Test of Hardware: Materials and Structure

--Challenge: Key engineering trade-offs include designing large, rigid machines at a reasonable cost and using expensive, corrosion-resistant alloys for components in contact with the aggressive magnesium slurry to ensure a long service life.

3. The "Digital Twin" Gap: Simulation and Sensing Limitations

--Challenge: A major hurdle is the lack of robust online sensors to monitor the slurry state in real-time. Furthermore, the limitations of current Die Casting Simulation software in accurately modeling the complex multi-phase flow mean that process setup still relies heavily on empirical testing.

Series Conclusion

Across these three articles, we have journeyed from slurry preparation and process control to mold design and equipment challenges, fully analyzing the complexity of Magnesium Thixoforming. It is not a simple upgrade to die casting, but a systematic engineering discipline. Mastering this technology requires a deep, holistic understanding of every stage. It is this integrated expertise that allows us to provide our clients with the most advanced and reliable molding solutions in the ever-evolving world of lightweight manufacturing.