- Home

- >

- News

- >

- Industry Insights

- >

- What is Deburring?: A Manufacturer's Guide to the Causes and Types of Burrs

What is Deburring?: A Manufacturer's Guide to the Causes and Types of Burrs

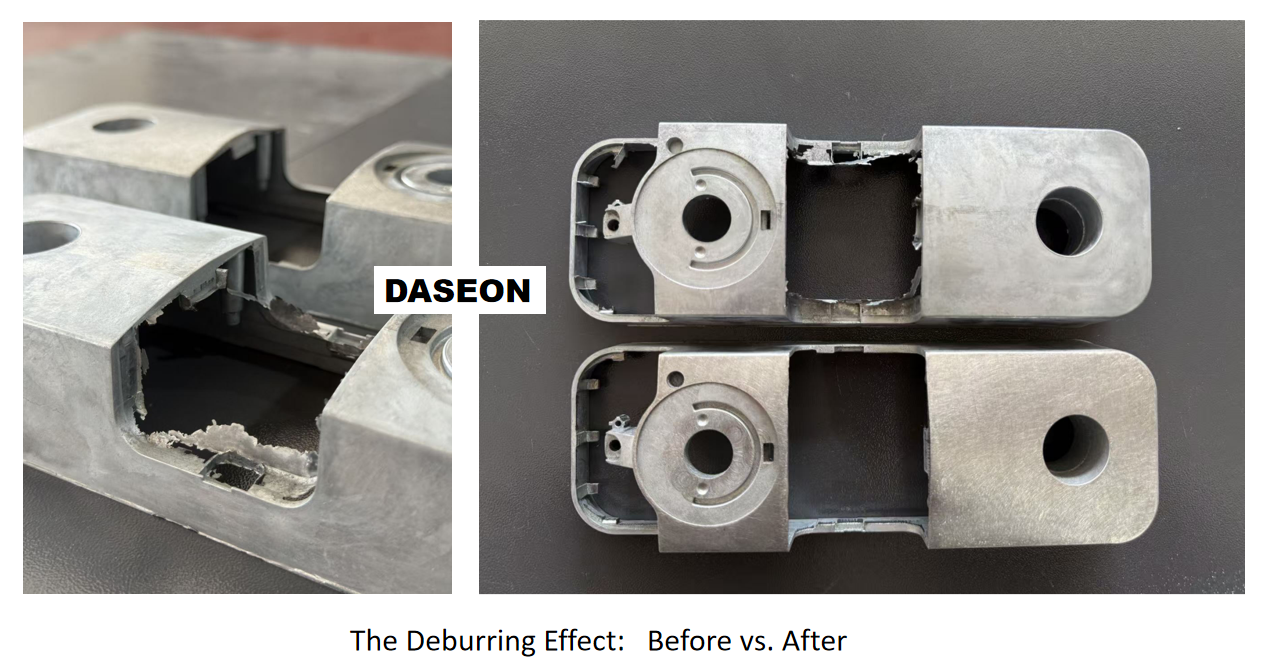

In the pursuit of precision and perfection in modern industrial manufacturing, every metal component undergoes a series of complex processes. However, even on the most advanced machinery, a tiny yet significant byproduct is almost inevitable: the burr. The process of removing these imperfections, known as "deburring," is the critical "last mile" in ensuring product quality and excellence.

I. What is a Burr, and Why Must We Remove It?

A burr is an unwanted raised edge or small piece of material that remains attached to a workpiece after a modification process like casting, machining, or cutting. Deburring, as the name implies, is the process of removing these extraneous objects.

Removing burrs is about much more than just aesthetics. These seemingly insignificant flaws can lead to a host of serious problems:

--Safety Hazards: Sharp burrs can easily cause injuries to operators during assembly and to end-users.

--Functional & Assembly Issues: Burrs can interfere with the fit and assembly of parts, leading to misalignment or improper seating. If a burr breaks loose during operation, it can enter critical systems (like hydraulic or lubrication lines), causing blockages or severe damage.

--Reduced Performance & Lifespan: Burrs can create stress concentrations, which act as initiation sites for cracks, significantly reducing a part's fatigue strength and service life.

--Impact on Subsequent Processes: Residual burrs can interfere with surface finishing processes like painting or plating, leading to poor adhesion and delamination.

Therefore, deburring is an essential process for improving product reliability, safety, and overall quality.

II. Where Do Burrs Come From? The Five Main Types by Origin

Understanding the origin of a burr is the first step in selecting the best removal method. Based on the formation process, we can generally classify burrs into five major types:

1. Casting BurrsDuring the liquid metal forming process, some material can escape from the seams (parting line) of a mold or from the roots of gates and risers. This type of burr is especially common on die-cast parts, and its size and shape are directly related to the precision and wear of the mold.

2. Forging BurrsIn the forging process, excess material is squeezed out from the die parting line due to the plastic deformation of the metal under pressure, forming a flash or burr.

3. Welding BurrsThese primarily come in two forms: during arc welding, droplets of filler material can splash onto the part surface, creating "spatter"; during gas welding or cutting, molten slag overflows from the cut and cools.

4. Stamping BurrsGenerated when stamping or shearing sheet metal, these burrs form due to the clearance between the punch and die, or because of wear on the cutting edges of the tool.

5. Machining BurrsThis is the most common and complex category of burrs. They are generated in nearly all machining operations, including turning, milling, planing, grinding, and drilling. Their shape, size, and orientation are closely related to numerous factors, including the material's ductility, tool geometry, and cutting parameters (speed, feed, depth).

Conclusion

In summary, deburring is not just a simple "polishing" task but a precision process that is crucial to a product's final quality. Correctly identifying the type and origin of a burr is the foundation for completing this work efficiently and effectively.

This article has introduced the fundamentals of burrs. However, how to remove these annoying imperfections efficiently and economically—especially in the mass production of die-cast parts—requires a systematic methodology and professional tools. In our upcoming series of articles, we will delve into deburring methods for die-cast parts, automated solutions, and tool selection. Please stay tuned for our updates!