The 300T semi-solid injection molding machine sets a new benchmark for thin-wall component production in the 3C and medical industries.

Designed as an entry-level solution for magnesium alloy semi-solid forming, the 300T machine specializes in producing thin-wall components for 3C electronics, small household appliances, and precision industrial parts. Its core strengths lie in high-speed performance, environmental sustainability, and micron-level precision, meeting the demands for efficient production of intricate thin-wall components.

1.Technological Breakthroughs:

1.1 Toggle-Type Mold Clamping System

Hydraulically driven dual-toggle mechanism achieves 0.3-second rapid clamping, paired with servo motor-driven gear adjustment for ±0.05mm positioning accuracy, ideal for high-cycle manufacturing of thin-wall components.

1.2 5m/s Ultra-High-Speed Injection

Non-contact displacement sensors monitor real-time injection curves, delivering 110MPa injection pressure and 9031cm³/s theoretical injection rate. This ensures semi-solid magnesium slurry fills mold cavities precisely before solidification, critical for thin-wall component quality.

1.3 Closed-Loop Temperature Control

PID-regulated barrel and nozzle heating (±1℃ fluctuation) combined with servo-controlled screw rotation (10-300r/min) stabilize slurry solid fraction, enabling consistent thin-wall component production.

1.4 Eco-Safe Design

Innovative technology uses SF6-free protective gas with direct charging of scrap magnesium alloy via fully enclosed smelting, achieving zero exhaust emissions while ensuring environmental sustainability and operational safety.

2. Application Scenarios & Customer Value

2.1 Typical Cases:

Laptop Housings: 0.8-1.2mm wall thickness with Ra≤0.8μm surface finish, achieving ≥98% yield improvement over die casting for thin-wall components.

Mobile Phone Mid-Frames: Multi-core pull-out support enables one-piece forming, reducing post-processing steps for complex thin-wall components.

Power Tool Gearboxes: Semi-solid process enhances material density, improving fatigue life by 40% for high-stress thin-wall components.

Medical Devices: Production of orthopedic implant scaffolds using semi-solid forming process to prevent turbulence in molten metal.

2.2 Customer Benefits:

Cost Efficiency: 92% material utilization (vs. 65% for die casting) energy reduction in thin-wall component production.

Rapid Turnaround: T-slot mold installation enables ≤15-minute changeovers, supporting small-batch, multi-variety thin-wall component manufacturing.

Compliance Assurance: CE-certified environmental requirements for thin-wall component production.

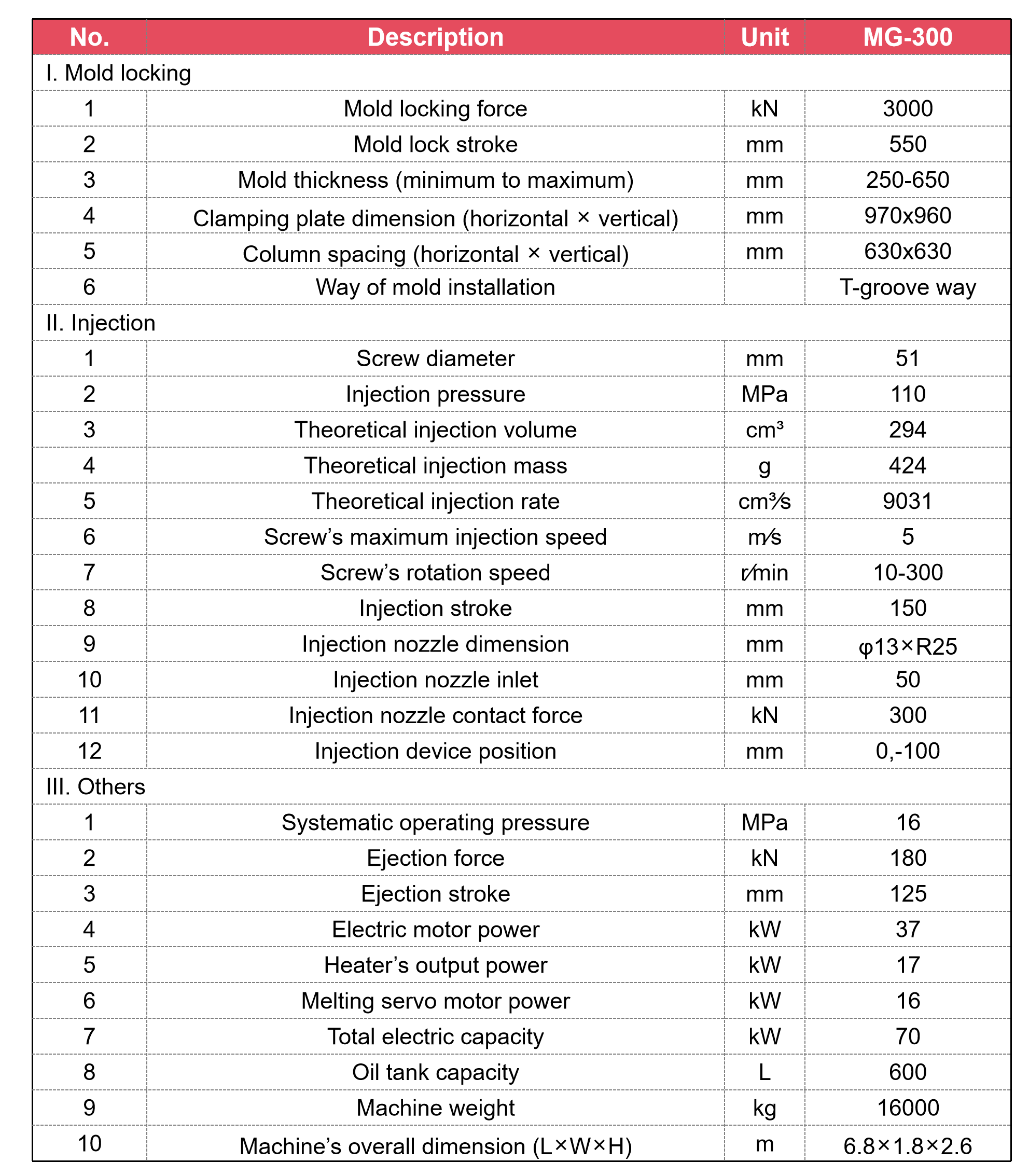

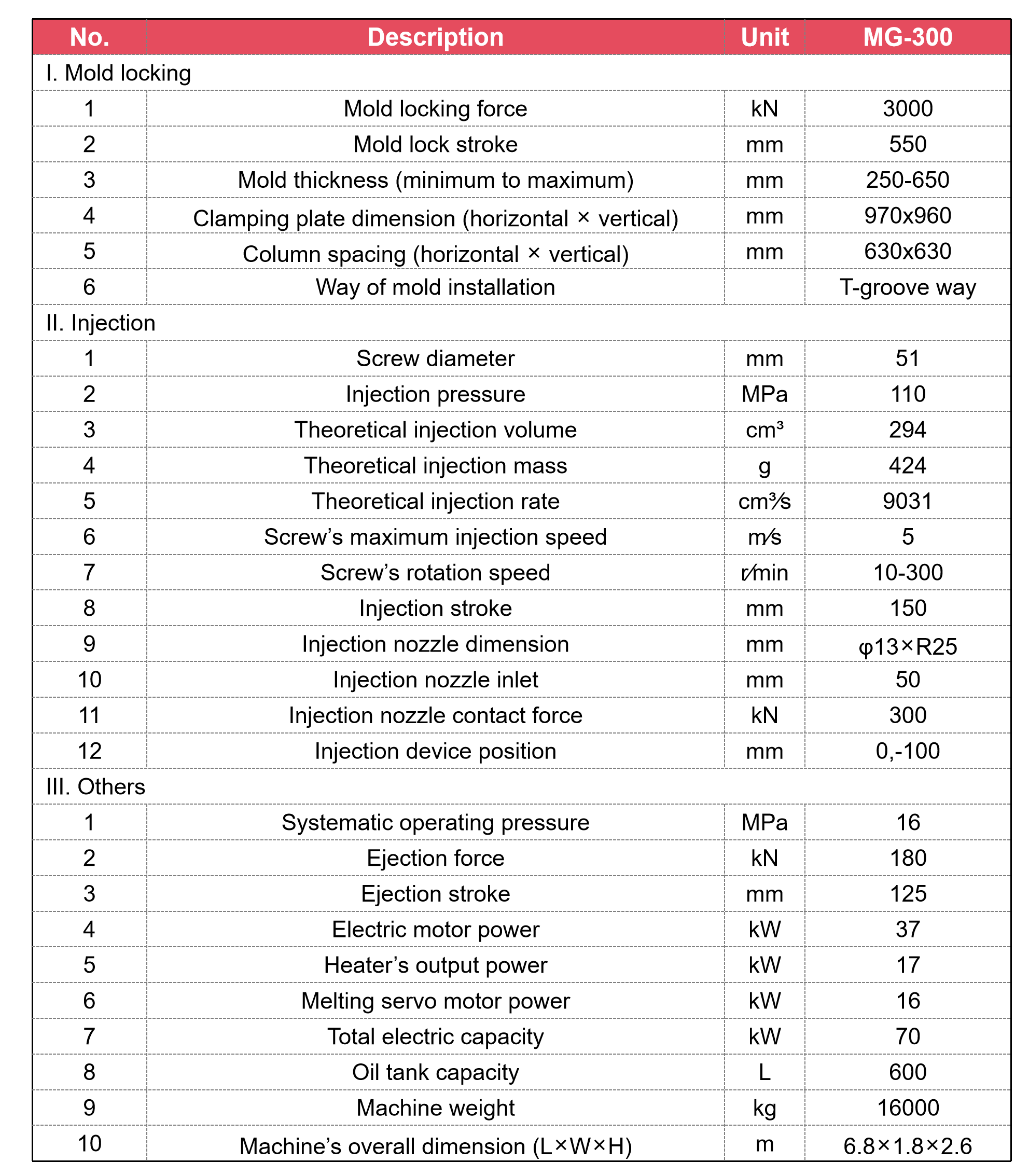

3. Technical Specifications

| Item | Specification | Industry Relevance |

|---|

| Clamping Force | 3000kN | Supports molds ≤0.5㎡ projected area |

| Theoretical Shot Volume | 294cm³ | Max. part weight 424g per cavity |

| Screw Diameter | 51mm | Optimized shear rate for thin-wall components |

| Injection Speed | 5m/s | Fastest in class for thin-wall components |

| Total Power | 70kW | 28% energy savings over conventional models |

4.Parameter

Summary

The 300T semi-solid injection molding machine has combination of 5m/s injection speed, closed-loop temperature control, and eco-friendly design delivers unmatched precision and cost efficiency. With CE certification and compliance with global safety standards, this model is poised to become the preferred choice for manufacturers worldwide seeking to transition to advanced magnesium processing. By leveraging its compact footprint and modular capabilities, the 300T machine bridges the gap between high-volume production and sustainable manufacturing, driving innovation in lightweight engineering for thin-wall components.