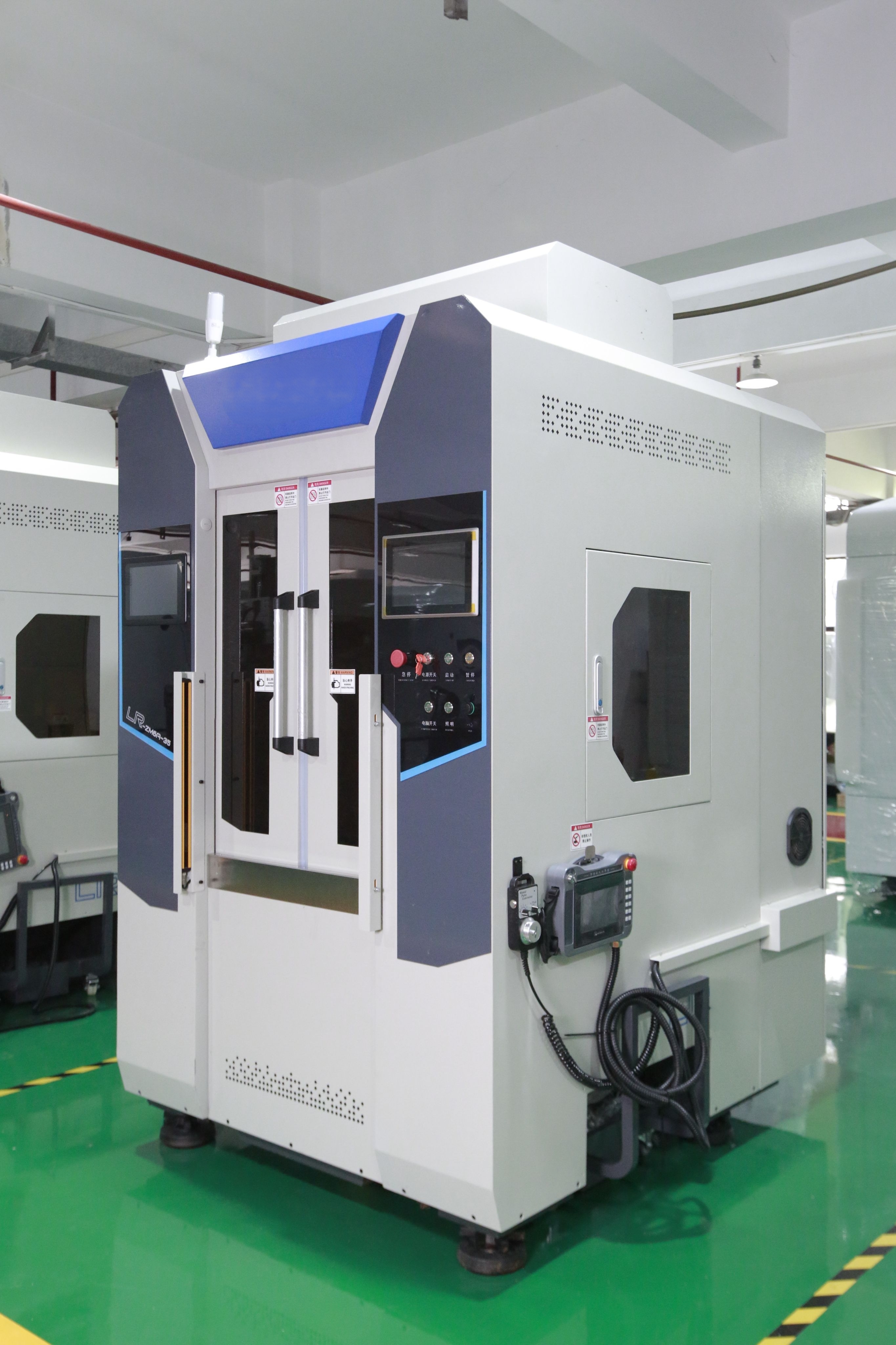

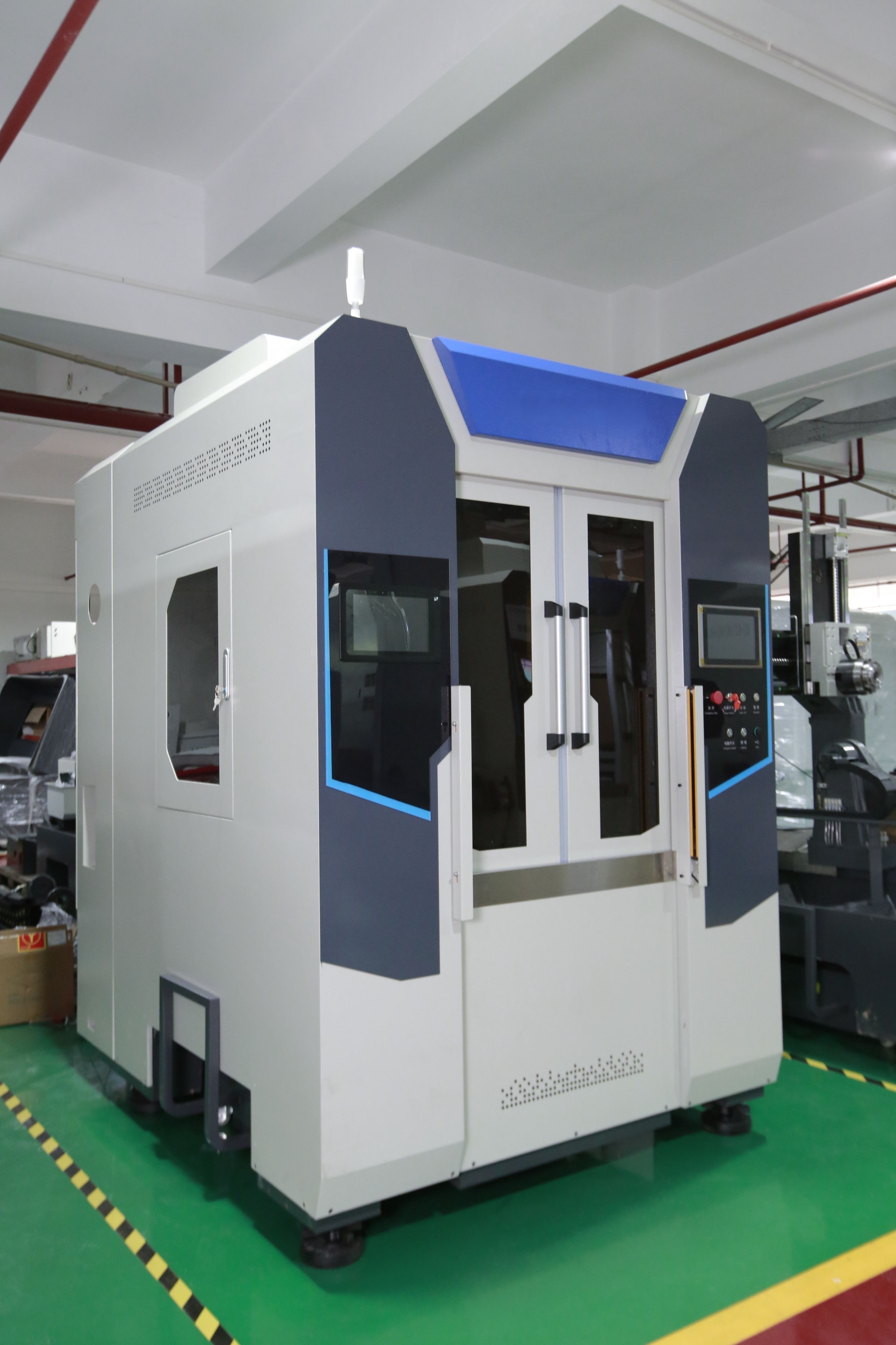

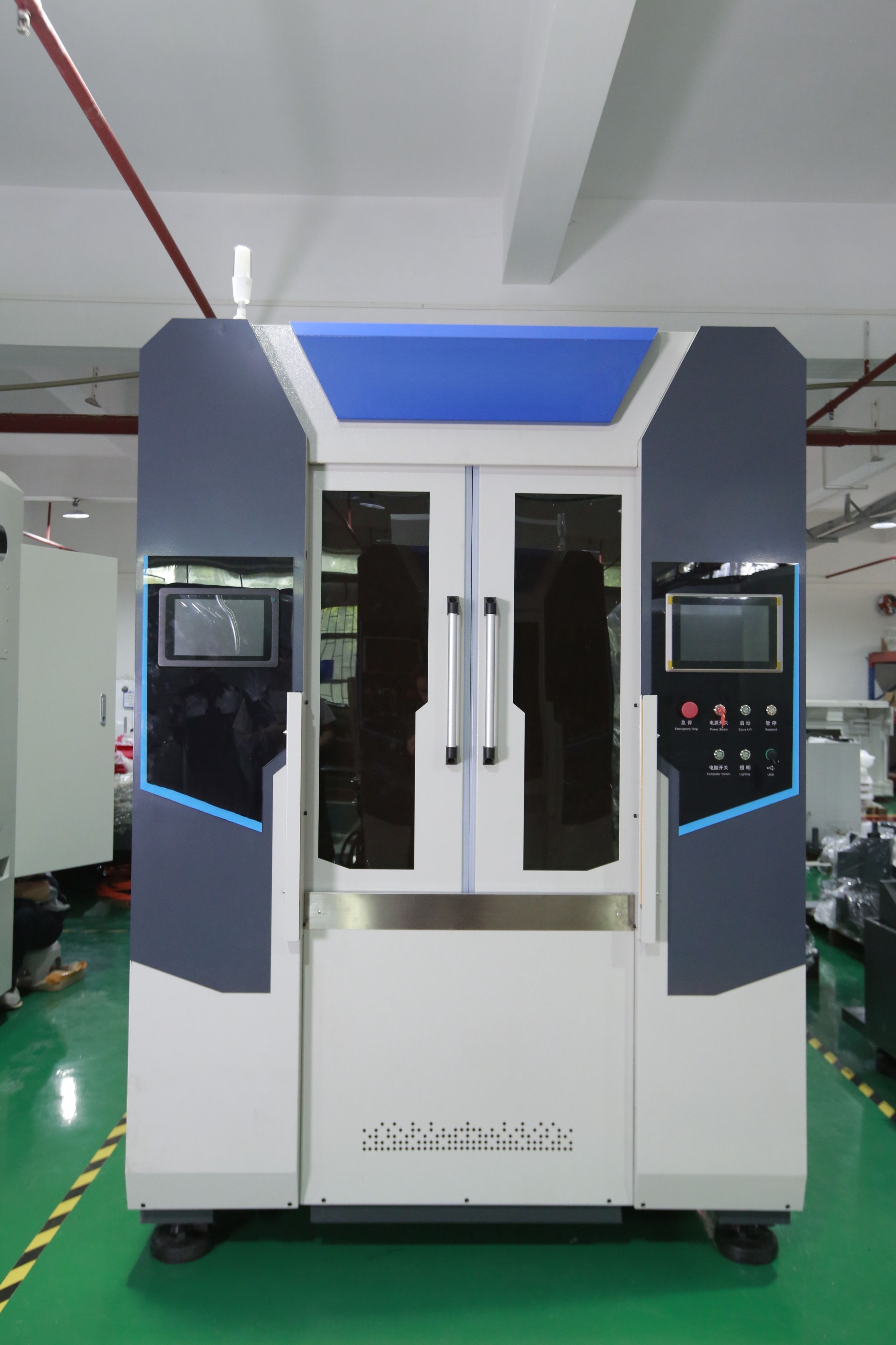

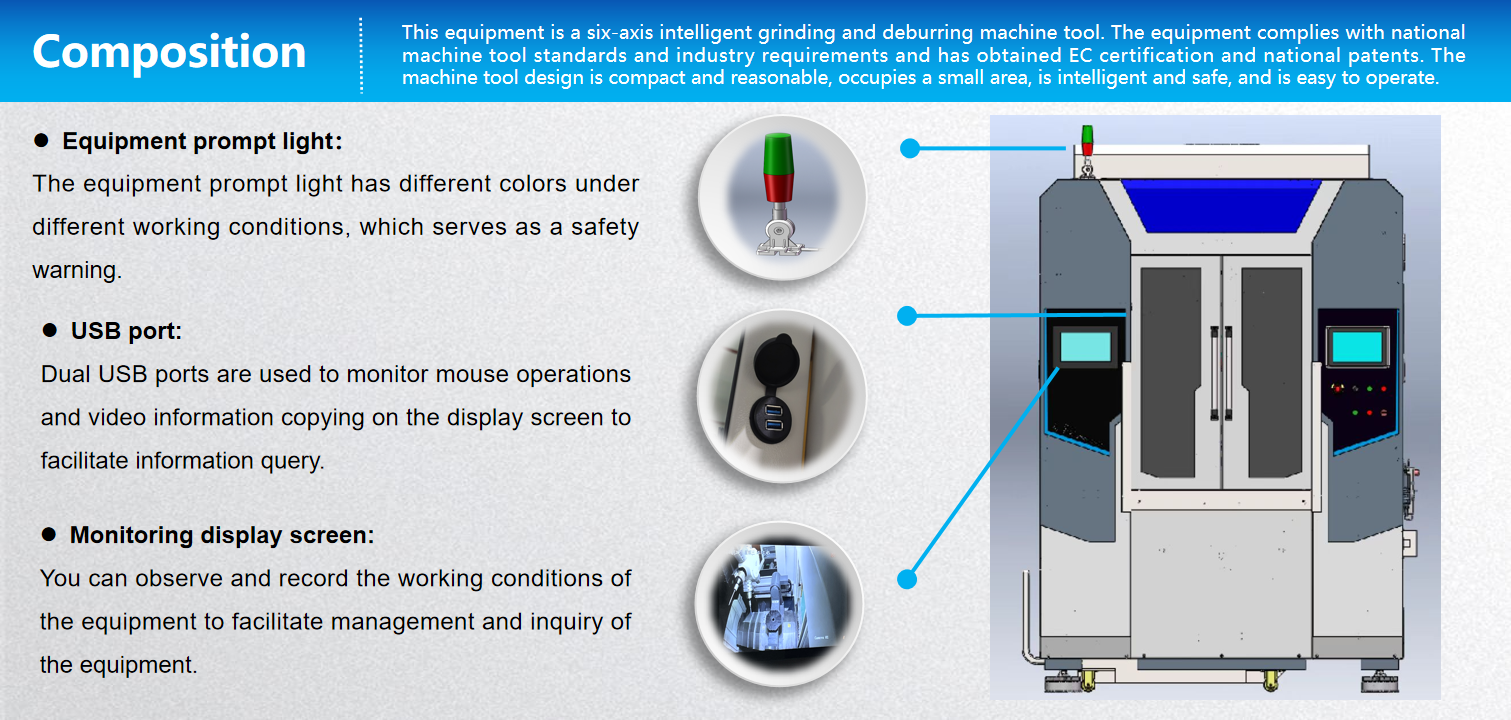

LR-ZM6A-35 robotic deburring machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The 6-Axis deburring cell by DASEON redefines precision machining in space-constrained manufacturing environments,it combines agility with industrial-grade accuracy.

In the fast-evolving landscape of industrial automation, the LR-ZM6C-35 Precision Deburring Machine stands as a testament to innovation, offering a Compact Deburring Solution designed for precision machining across diverse sectors. Engineered with smart automation and micro-precision technology, this machine redefines efficiency in Medical Device Grinding and automotive component processing, catering to the rigorous demands of modern manufacturing.

Core Technical Features

1. Precision Machining Architecture for Diverse Applications

The LR-ZM6C-35 Precision Deburring Machine is built around a robust framework and smart automation optimized for precision machining:

Ultra-Fine Positioning: Achieves ≤0.02mm repeat accuracy on X/Y/Z axes, ensuring flawless deburring for intricate components in precision machining, from automotive brake calipers to medical implant connectors.

6-Axis Kinematic Flexibility: With A/B/C rotary axes (±110°/±190°/360°), it enables multi-angle access to complex geometries, a key feature in precision machining workflows that reduces setup time compared to conventional systems.

2. Compact Deburring Solution for Space-Efficient Production

As a Compact Deburring Solution, the machine balances power and portability:

Space-Saving Design: Dimensions of 1450×1750×2450mm and 2T weight make it ideal for tight workshop layouts, seamlessly integrating into automated cells or standalone operations as a Compact Deburring Solution.

High Mobility: Reinforced casters and forklift-compatible base allow quick repositioning, enhancing agility in dynamic manufacturing environments that rely on Compact Deburring Solution efficiency.

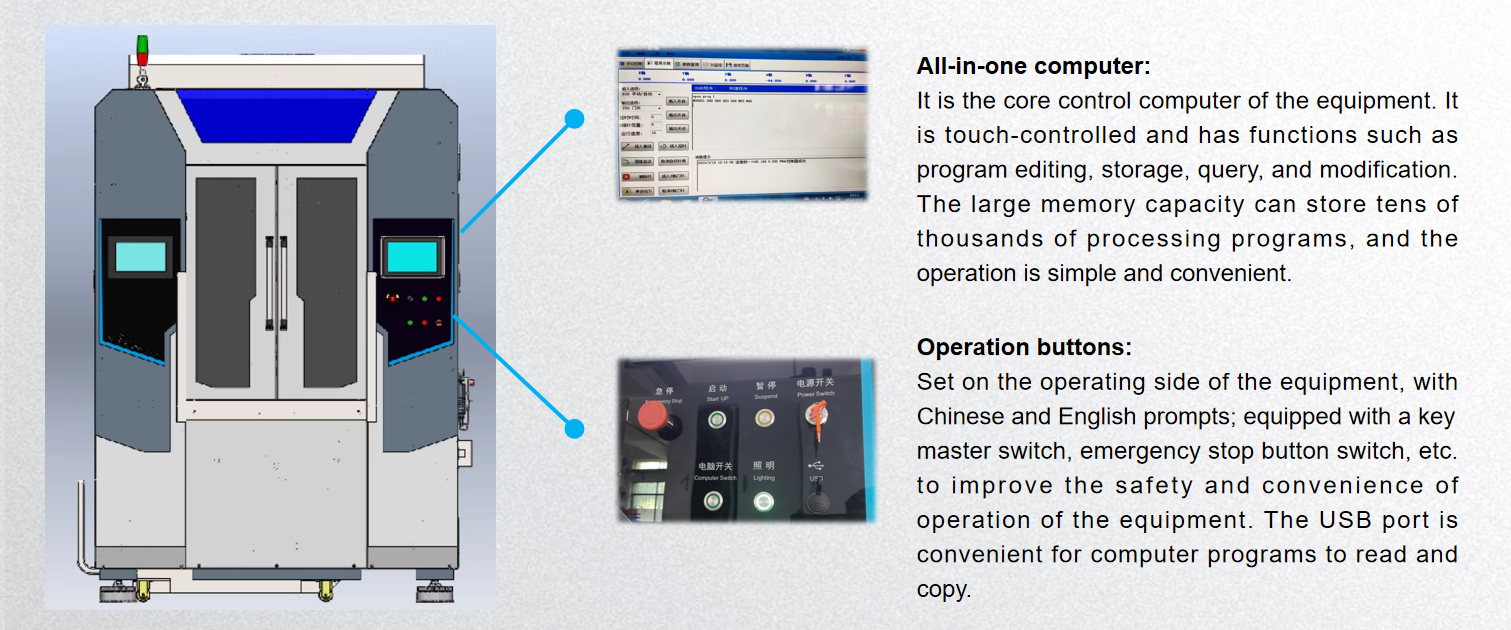

3. Smart Automation for Enhanced Operational Control

The smart automation capabilities of the LR-ZM6C-35 Precision Deburring Machine streamline processes:

OMRON Control System: Features advanced algorithms for toolpath optimization, reducing redundant motion by 40% in precision machining and Medical Device Grinding applications.

Dual-Mode Operation: Switches between high-volume batch processing and low-volume prototyping with one-click program retrieval, a core benefit of its smart automation design.

4. Specialized for Medical Device Grinding Requirements

In Medical Device Grinding, the smart automation machine excels through tailored technologies:

Hybrid Spindle Technology: Combines rigid (7.5kW) and floating (2.2kW) spindles to handle delicate medical materials like PEEK and titanium, achieving Ra 0.8μm finishes critical for Medical Device Grinding compliance.

Vision-Guided Calibration: 3D vision systems correction ensure precise deburring of micro-structured surfaces, essential for surgical instruments and implantable devices in Medical Device Grinding.

Industry Applications

1. Automotive Precision Machining Excellence

The LR-ZM6C-35 Precision Deburring Machine is a cornerstone in automotive precision machining:

Engine Components: Processes aluminum engine mounts and steel transmission parts with 6-axis precision, eliminating burrs that could affect assembly torque and structural integrity.

Chassis & Safety Parts: Ensures smooth finishes on steering knuckles and brake calipers, enhancing part durability and meeting automotive safety standards through precision machining.

High-Volume Production: It supports mass production of small fasteners and mid-sized brackets, powered by smart automation for consistent quality.

2. Medical Device Grinding Specialization

For Medical Device Grinding, the machine delivers unmatched precision:

Surgical Instruments: Deburrs forceps, cannulas, and endoscopic components with adaptive force control , preventing deformation and ensuring biocompatible surface finishes.

Implantable Devices: Processes titanium alloy knee implants and dental prosthetics, using vision-guided technology to follow anatomical contours for optimal osseointegration.

Regulatory Compliance: Closed-loop dust management captures of particulates, making it suitable for medical manufacturing environments focused on Medical Device Grinding and smart automation.

3. Electronics & Precision Engineering

In micro-scale manufacturing, the LR-ZM6C-35 Precision Deburring Machine shines in precision machining:

Electronics Components: Removes burrs from micro-connectors and PCB brackets , ensuring flawless electrical conductivity in high-reliability devices.

Optical & Watch Parts: Achieves mirror-like finishes on delicate components, leveraging 6-axis flexibility to maintain complex geometries without compromise.

Industry-Tailored Advantages

1. Unmatched Precision Machining Performance

Consistency: Cpk >1.67 process capability ensures uniform results across materials, outperforming manual methods and legacy systems in precision machining.

Material Versatility: Adapts to aluminum, steel, titanium, and medical-grade polymers, making it a versatile choice for diverse precision machining needs.

2. Smart Automation-Driven Efficiency

Reduced Downtime: Rapid tool changes (90 seconds) and automated program retrieval, powered by smart automation, boost productivity compared to conventional deburring.

Energy Savings: Low-power mode reduces energy consumption during standby, aligning with sustainable manufacturing goals.

3. Compact Deburring Solution Benefits

Space Optimization: Small footprint fits into tight production lines, ideal for lean manufacturing environments where every millimeter matters.

Cost Efficiency: Minimizes material waste and tool wear through intelligent compensation, delivering long-term cost savings as a Compact Deburring Solution.

4. Medical Device Grinding Compliance

Traceability: Built-in process logging meets critical for medical device manufacturers.

Safety Features: Fully enclosed structure with emergency stop, fire suppression and smart automation, ensuring operator safety during Medical Device Grinding of hazardous materials.

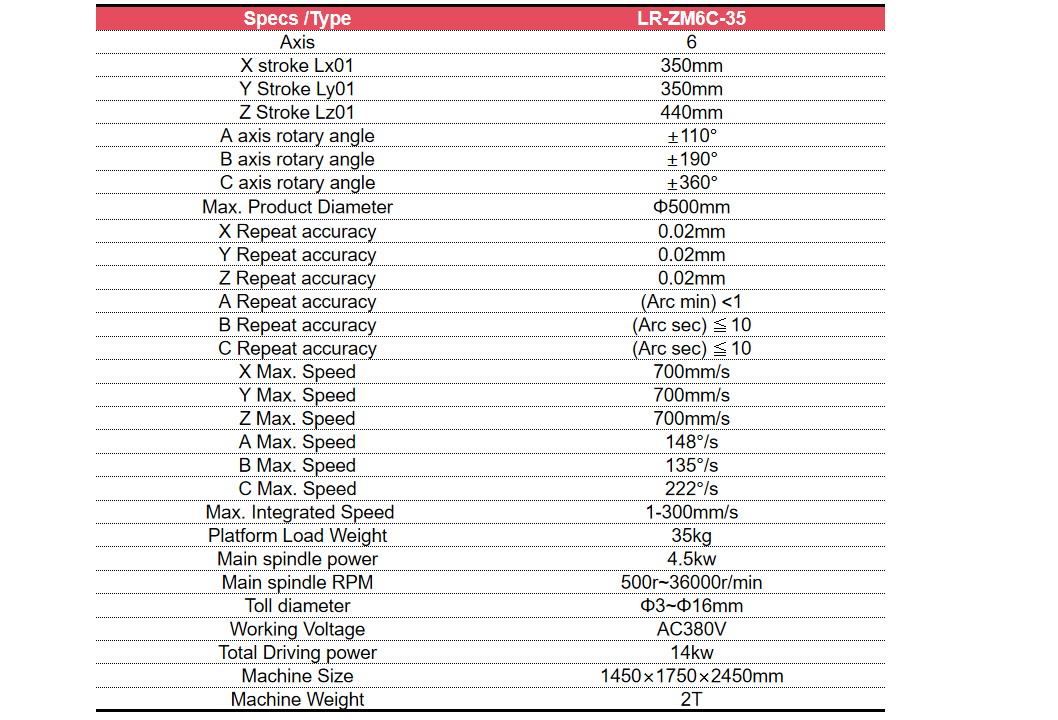

Parameter

Conclusion

The LR-ZM6C-35 Precision Deburring Machine combines precision machining, smart automation, and Compact Deburring Solution design to address the complex needs of automotive, medical, and electronics industries.