LR-ZM6B-90 CNC Grinding Cell

Brand :Daseon

Product origin :China

Delivery time :30 Days

Traditional solutions struggle with the dual requirements of high-capacity workpiece handling and precision tolerances, leading to inefficiencies in both quality and productivity. The LR-ZM6B-90 High-Capacity Deburring Machine addresses this gap.

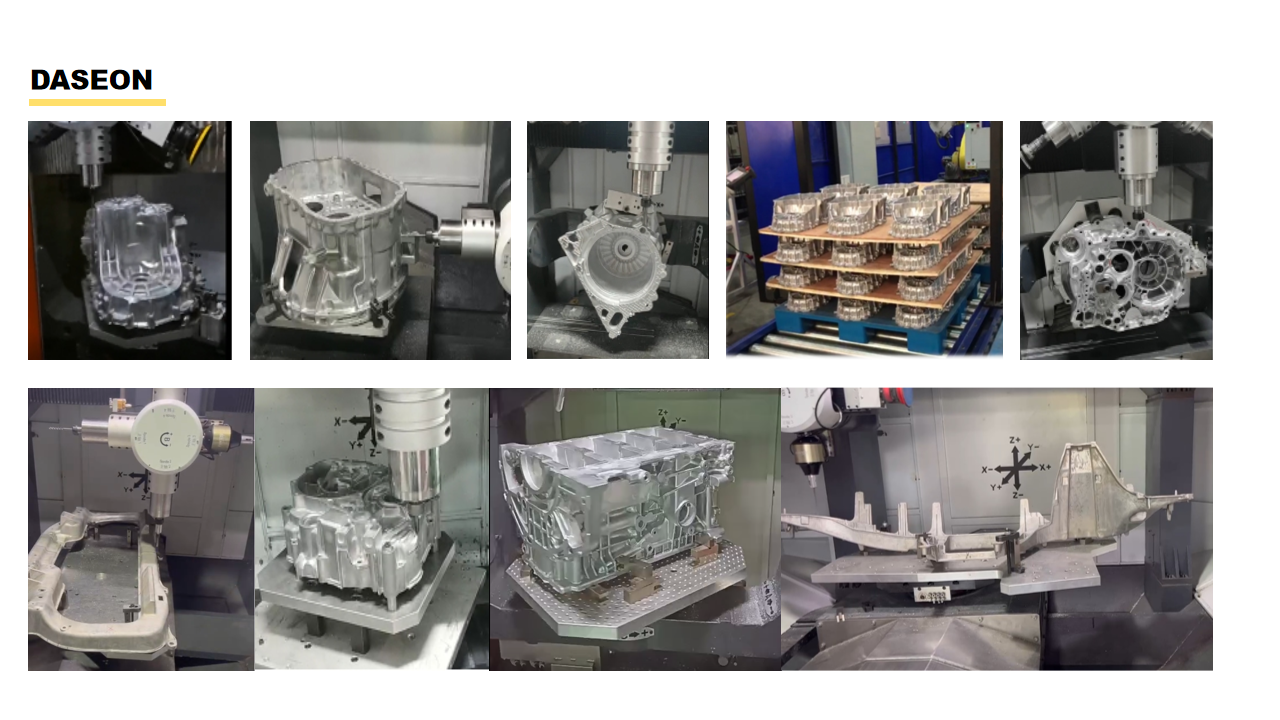

In the evolving landscape of modern manufacturing, the LR-ZM6B-90 Mid-Scale Deburring System emerges as a pivotal solution, designed to meet the complex demands of industries such as aerospace, energy storage, and heavy machinery. This system integrates cutting-edge Industrial Automation with superior Precision Machining capabilities, offering specialized solutions for Battery Tray production and Aerospace Aluminum Deburring while ensuring optimal efficiency for medium to large components.

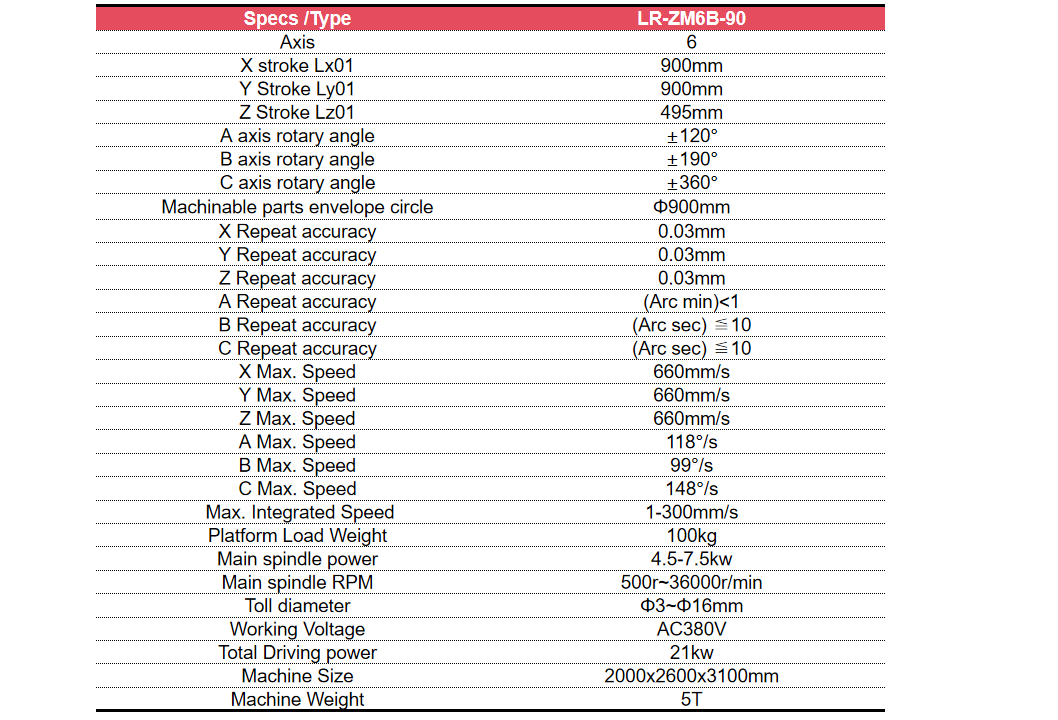

Core Technical Specifications of the Mid-Scale Deburring System

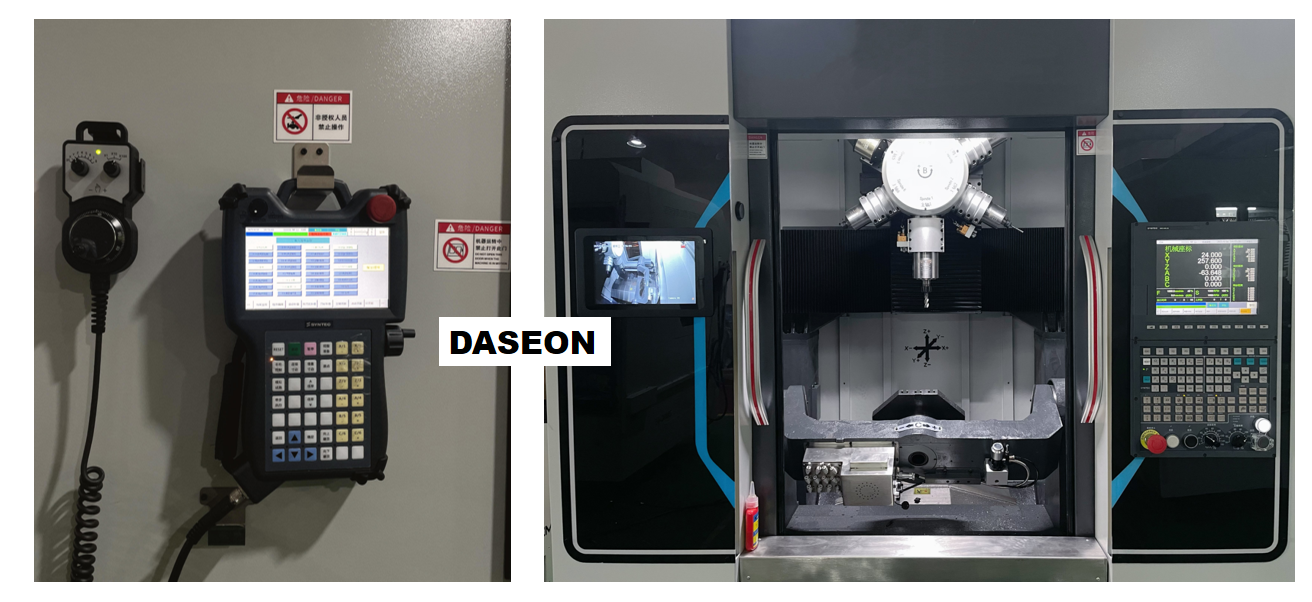

1. SYNTEC-Powered Industrial Automation Core

The Mid-Scale Deburring System is driven by the SYNTEC 6-Axis CNC System, a benchmark of Industrial Automation that enables unparalleled motion control:

Axis Configuration: X/Y/Z linear axes (900mm/900mm/495mm strokes) + A/B/C rotary axes (±120°/±190°/±360°), allowing precise multi-angle access critical for Precision Machining in Battery Tray and Aerospace Aluminum Deburring applications.

Speed & Accuracy: With linear axes reaching 660mm/s and a repeat accuracy of ≤0.03mm, the system balances Industrial Automation-driven speed with the tight tolerances required for aerospace aluminum components and battery tray flatness.

2. Precision Machining Excellence

The Mid-Scale Deburring System excels in Precision Machining across diverse materials, supported by its robust hardware.

Dual-Spindle Technology: Combines a 7.5kW rigid spindle for heavy material removal and a 4.5kW floating spindle for delicate finishing, precision machining of battery tray aluminum and aerospace aluminum alloys.

Intelligent Tool Management: Laser-guided automatic tool compensation and breakage detection ensure minimal errors during Precision Machining, extending tool life , a key benefit for Aerospace Aluminum Deburring and high-volume Battery Tray production.

3. Modular Design for Adaptive Manufacturing

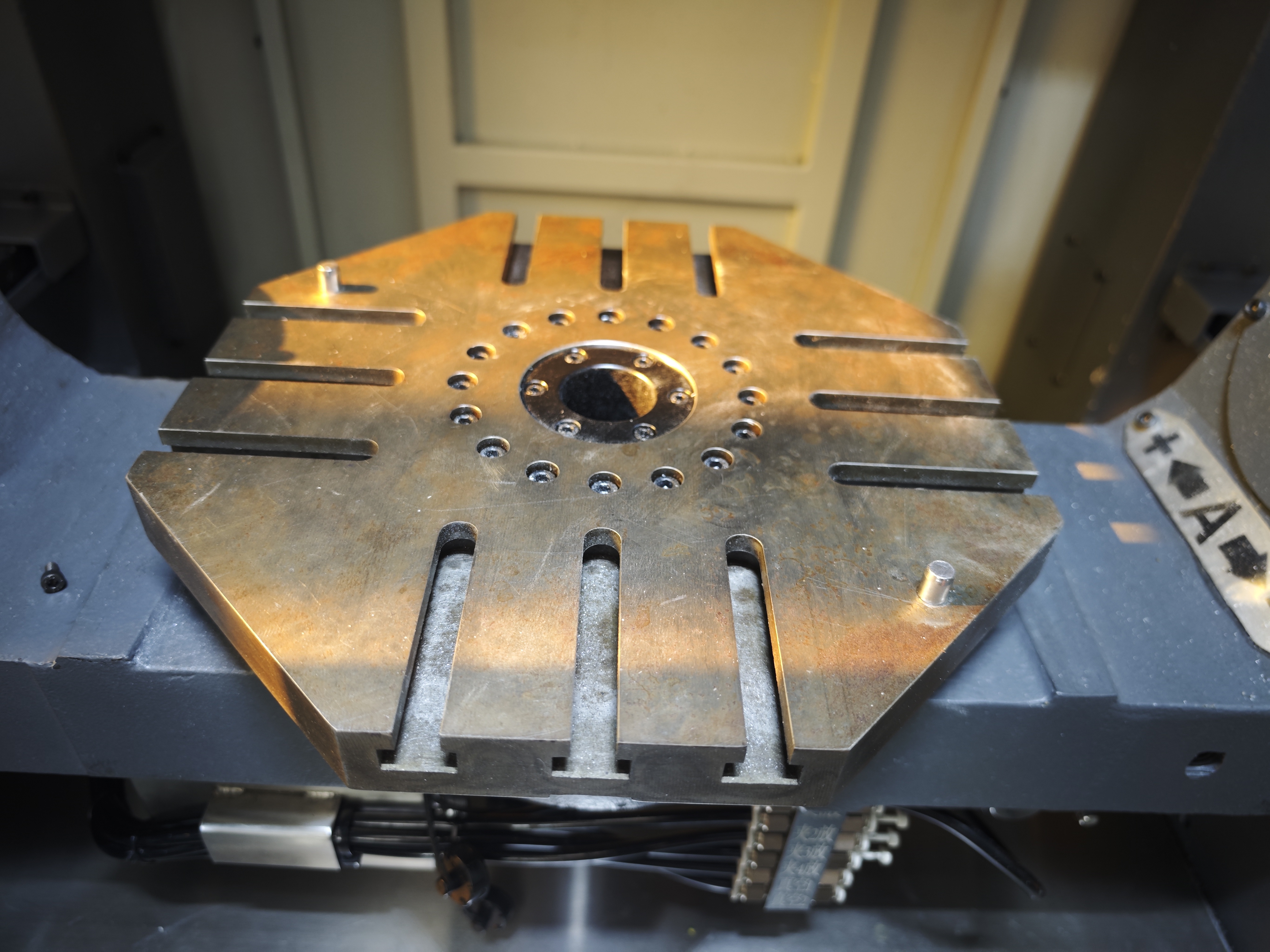

The system’s industrial-grade build caters to varied workholding needs:

Quick-Change Fixtures: Pneumatic clamps and 1:2 locating pins enable fixture swaps, ideal for switching between Battery Tray castings and aerospace aluminum extrusions requiring specialized Aerospace Aluminum Deburring.

Safety & Compliance: IP54-rated enclosure with safety light curtains complies, ensuring operator safety during Industrial Automation-driven operations.

Industry Applications of the Mid-Scale Deburring System

1. Battery Tray Production Optimization

The Mid-Scale Deburring System revolutionizes Battery Tray manufacturing in electric vehicles:

Thermal Management Precision: Processes complex cooling channels with Precision Machining,to optimize heat dissipation and battery performance.

Automation-Driven Efficiency: Industrial Automation reduces cycle times compared to manual methods, while closed-loop dust extraction ensures cleanroom compliance for safe Battery Tray assembly.

Structural Integrity: Precision Machining of ribbed structures enhances tray stiffness, reducing deformation risks during battery module and battery tray installation.

2. Aerospace Aluminum Deburring Compliance

For aerospace applications, the system meets standards in Aerospace Aluminum Deburring:

Complex Geometry Processing: 6-axis Industrial Automation enables burr removal from titanium-aluminum alloy turbine brackets and wing components.

Nondestructive Finishing: Precision Machining with floating spindles polishes aluminum surfaces , critical for aerodynamic efficiency and corrosion resistance in aerospace components.

Material Preservation: Adaptive force control during Precision Machining prevents micro-cracks in thin-walled aerospace parts, ensuring structural integrity.

3. Heavy Machinery & General Industrial Use

The Mid-Scale Deburring System delivers reliable performance in non-specialized sectors:

Hydraulic Manifolds: Cleans deep steel cavities with Industrial Automation-optimized toolpaths.

Industrial Pump Housings: Uses adaptive force control during Precision Machining to eliminate flow restrictions, improving operational efficiency for industrial equipment.

Operational Efficiency Driven by Industrial Automation

1. Smart Programming & Connectivity

The system’s Industrial Automation features streamline production workflows:

3D CAD Direct Import: SYNTEC controller generates optimized toolpaths from STEP files,faster than manual coding and ideal for Battery Tray ribs and aerospace aluminum lattice structures.

Industry Integration: Enabled real-time monitoring tracks spindle load, tool wear, and temperature, supporting predictive maintenance and reducing unplanned downtime.

2. Energy-Efficient Operations

The Mid-Scale Deburring System prioritizes sustainability through Industrial Automation:

Adaptive Power Management: Reduces idle energy consumption, aligning with global green manufacturing goals for Battery Tray and aerospace production.

Waste Reduction: Closed-loop coolant recycling and 35% particulate waste recovery system, ensuring eco-friendly operations during Aerospace Aluminum Deburring and heavy machining tasks.

Parameter

Conclusion

The LR-ZM6B-90 Mid-Scale Deburring System is a versatile, high-precision solution that combines Industrial Automation, Precision Machining, and specialized expertise in Battery Tray and Aerospace Aluminum Deburring. Its modular design, smart connectivity, and robust performance make it ideal for manufacturers seeking to optimize production across diverse industries.