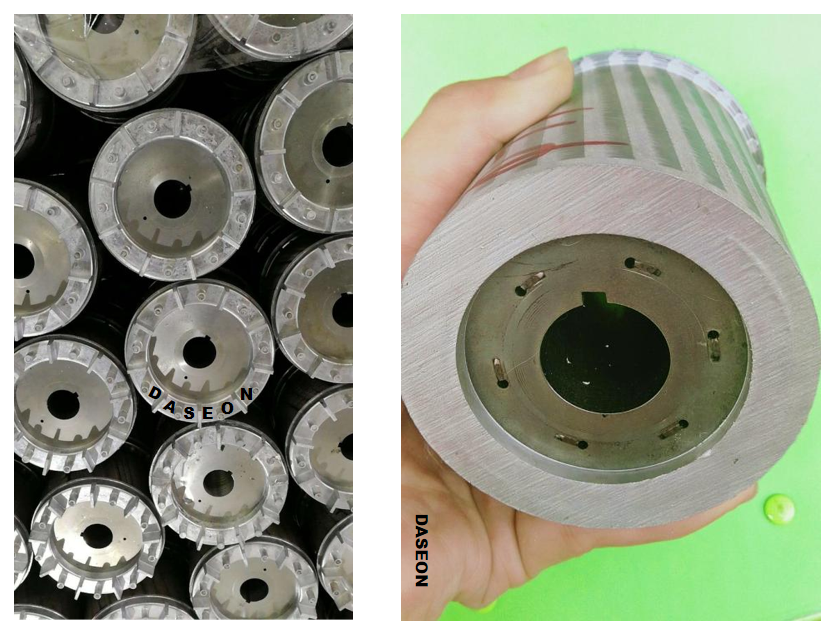

MRK100 Fully Automatic Vertical Motor Rotor Die Casting Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The MRK100 high-pressure multi-stage casting system is engineered for large-scale, high-precision production of industrial rotors, such as those used in wind turbines, electric vehicle (EV) motors, and heavy machinery.

With a clamping force of 1,000 kN and compatibility with high-temperature materials (e.g., copper alloys), this system delivers unmatched durability and efficiency for complex, high-load applications. Its multi-stage injection technology ensures optimal mold filling and minimal porosity, even for rotors exceeding 500 mm in diameter.

Key Advantages of MRK100

1.High-Pressure Multi-Stage Injection

--The high-pressure multi-stage casting system combines slow-fill and rapid-pressurization phases to eliminate air pockets and ensure dense, defect-free rotors—critical for high-stress environments (e.g., EV drivetrains).

--Achieves porosity rates below 1%, surpassing industry benchmarks for copper and aluminum rotors.

2.Industrial-Grade Durability

--Mold plates and tie bars use Swedish 8418 steel, heat-treated to withstand temperatures up to 800°C, extending mold lifespan by 30% compared to standard materials.

--Reinforced gantry structure reduces vibration during operation, maintaining alignment accuracy within ±0.02 mm.

3.Scalable Automation

--Integrated robotic extractors and conveyor systems enable fully automated production lines, reducing manual handling by 60%.

--IoT-enabled monitoring provides real-time data on machine performance and predictive maintenance alerts.

3.Energy Efficiency

--Variable-frequency drives (VFDs) optimize hydraulic pump output, cutting energy consumption by 15–20% during idle phases.

MRK Series Comparison: Aligning Models with Needs

| Model | Clamping Force | Core Strength | Ideal Applications | Key Differentiator |

|---|---|---|---|---|

| MRK40 | 400 kN | Cost-effective, compact design | Small rotors (e.g., household appliances) | Rapid mold change, low energy use |

| MRK63 | 630 kN | Vacuum-assisted precision | Medium rotors (e.g., HVAC fans) | Porosity control, multi-cavity molds |

| MRK100 | 1,000 kN | High-pressure multi-stage casting | Large industrial rotors (e.g., wind turbines) | Ultra-durable molds, copper alloy compatibility |

| MRK160+ | 1,600–5,000 kN | Heavy-duty production | Mega-scale rotors (e.g., marine engines) | Extreme clamping force, IoT integration |

Why Choose MRK100?

For High-Temperature Applications: If your production involves copper alloys or requires molds to withstand prolonged thermal stress, the high-pressure multi-stage casting system ensures consistent quality and longevity.

For Large-Volume Demands: Designed for 24/7 operation, MRK100 achieves daily outputs of 1,500–2,000 units, ideal for industries like renewable energy and automotive manufacturing.

For Precision Engineering: CNC-machined components and real-time monitoring guarantee tolerances within ±0.05 mm, meeting aerospace and automotive standards.

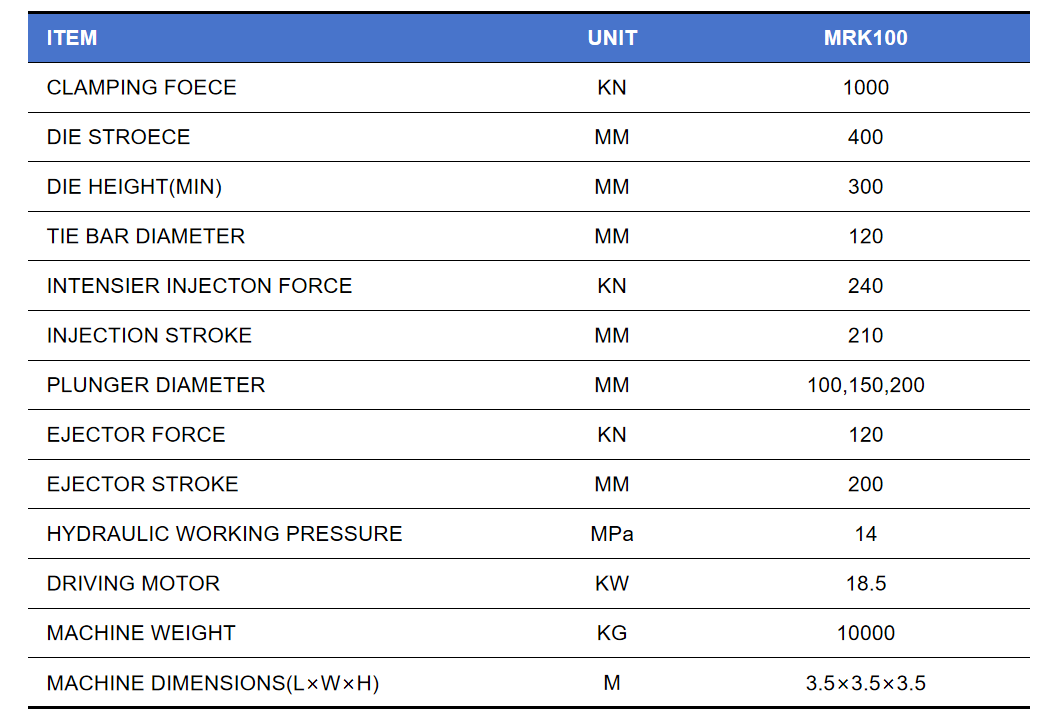

Technical Specifications

Conclusion

The MRK100 high-pressure multi-stage casting system is the cornerstone of industrial rotor manufacturing, combining brute-force clamping power with precision engineering. While the MRK40 and MRK63 excel in smaller-scale applications, the MRK100 dominates in sectors demanding extreme durability and high-temperature resistance, such as renewable energy and electric mobility.

By transparently presenting each MRK model’s strengths, we empower clients to select the solution that aligns with their production scale, material needs, and quality targets—ensuring efficiency, reliability, and long-term competitiveness.