MRK160 Fully Automatic Vertical Motor Rotor Die Casting Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The MRK160 ultra-high clamping force casting system is engineered for industrial-scale production of large and complex rotors, such as those used in wind turbines, marine engines, and heavy-duty electric vehicle (EV) motors.

With a clamping force of 1,600 kN, this system combines brute power with precision engineering to handle high-temperature materials like copper alloys and advanced composites. Its multi-stage injection technology and IoT-enabled monitoring ensure consistent quality and efficiency, even for rotors exceeding 600 mm in diameter.

Key Advantages of MRK160

1.Ultra-High Clamping Force

--The ultra-high clamping force casting system delivers 1,600 kN of clamping pressure, ensuring mold stability and minimizing flash during high-pressure injection—critical for large rotors requiring tight dimensional tolerances.

--Achieves low porosity rates for copper alloy rotors, surpassing industry standards for high-stress applications.

2.Advanced Multi-Stage Injection

--Three-stage injection (slow fill, high-speed fill, and intensification) optimizes mold filling and reduces internal defects, even for thick-walled rotors (>20 mm).

--Compatible with materials requiring melting temperatures up to 1,200°C, such as bronze and specialty steels.

3.Industrial IoT Integration

--Real-time monitoring via embedded sensors tracks machine performance, hydraulic pressure, and mold temperature, enabling predictive maintenance and reducing unplanned downtime.

--Data export to factory management systems (e.g., MES) supports seamless integration into smart manufacturing workflows.

4.Energy Efficiency

--Regenerative hydraulic systems recover energy during deceleration phases, cutting power consumption compared to conventional systems.

MRK Series Comparison: Aligning Models with Needs

| Model | Clamping Force | Core Strength | Ideal Applications | Key Differentiator |

|---|---|---|---|---|

| MRK40 | 400 kN | Compact, cost-effective design | Small rotors (e.g., household appliances) | Rapid mold change, low energy use |

| MRK63 | 630 kN | Vacuum-assisted precision | Medium rotors (e.g., HVAC fans) | Porosity control, multi-cavity molds |

| MRK100 | 1,000 kN | High-pressure multi-stage casting | Industrial rotors (e.g., wind turbines) | Copper alloy compatibility, IoT readiness |

| MRK160 | 1,600 kN | Ultra-high clamping force | Mega-scale rotors (e.g., marine engines) | Industrial IoT, extreme material compatibility |

| MRK200+ | 2,000–5,000 kN | Heavy-duty production | Specialized applications (e.g., aerospace) | Customizable, mega-tonnage capability |

Why Choose MRK160?

1.For Mega-Scale Production: If your operations demand high-volume output of large rotors (e.g., offshore wind turbine components), the ultra-high clamping force casting system ensures stability and precision at scale.

2.For Extreme Material Challenges: Designed to handle copper alloys and advanced composites, MRK160 is ideal for rotors requiring thermal resistance (e.g., EV traction motors).

3.For Smart Factories: IoT integration and predictive maintenance tools align with Industry standards, enabling data-driven optimization.

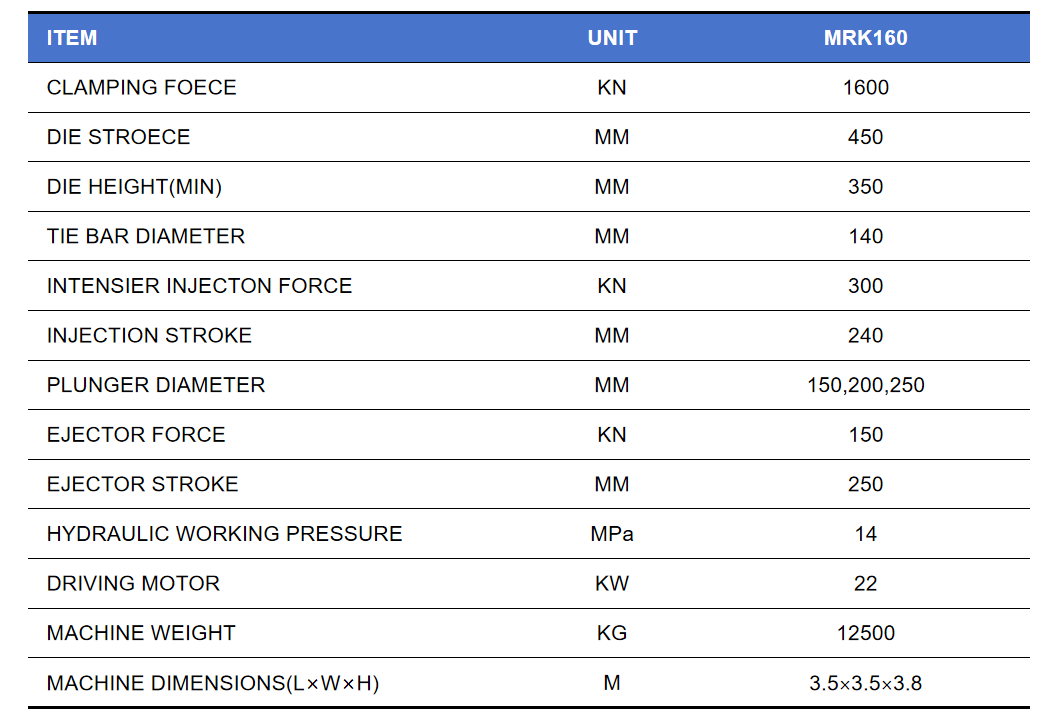

Technical Specifications

The MRK160 ultra-high clamping force casting system redefines industrial rotor manufacturing by combining unmatched clamping power with smart technology integration. While the MRK40 and MRK63 cater to smaller-scale precision needs, and the MRK100 bridges medium-to-heavy applications, the MRK160 dominates in sectors requiring mega-scale production and extreme material versatility, such as renewable energy and marine engineering.