MRK63 Fully Automatic Vertical Motor Rotor Die Casting Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The MRK63 vacuum-assisted rotor casting system is designed for manufacturers requiring precision and scalability in medium-sized rotor production.

With a clamping force of 630 kN and advanced vacuum die-casting technology, this system excels in producing complex geometries (e.g., fan rotors, blade-integrated designs) while minimizing porosity to <1.5%. Its semi-automated workflow supports cycle times of 15–22 seconds, making it ideal for high-volume batches in industries like HVAC, automotive, and industrial machinery.

Key Advantages of MRK63

1.Vacuum Die-Casting Technology

--The vacuum-assisted rotor casting system integrates a sealed chamber during injection, eliminating air entrapment and achieving low surface roughness, critical for rotors requiring high dynamic balance (e.g., precision fans).

--Reduces post-casting machining costs by 20–30% compared to traditional methods.

2.Scalable Automation

--Automatic ladling, spraying, and part extraction units minimize manual intervention, supporting 24/7 operation and reducing labor costs.

--Preset parameter storage allows quick switching between rotor types, cutting setup time.

3.Material Versatility

--Compatible with aluminum-silicon alloys, magnesium alloys, and zinc alloys, catering to lightweight or high-strength applications.

4.Energy Efficiency

--Energy recovery modules in the hydraulic system reduce power consumption, aligning with sustainable manufacturing goals.

MRK Series Comparison: Matching Models to Needs

To help clients identify the best-fit solution, here’s an objective overview of the MRK series’ strengths and typical use cases:

| Model | Clamping Force | Core Strength | Ideal Applications | Key Differentiator |

|---|---|---|---|---|

| MRK40 | 400 kN | Cost-effective, compact design | Small rotors (e.g., household appliances) | Rapid mold change (30 min), low energy use |

| MRK63 | 630 kN | Vacuum-assisted precision | Medium rotors (e.g., HVAC fans, blade-integrated designs) | Porosity control, multi-cavity molds |

| MRK100+ | 1,000–5,000 kN | Heavy-duty, high-pressure injection | Large industrial rotors (e.g., wind turbines, EV motors) | Ultra-high clamping force, copper alloy compatibility |

Why Choose MRK63

For Precision-Driven Industries: If your production requires minimal porosity (e.g., rotors for high-speed motors or noise-sensitive HVAC systems), the vacuum-assisted rotor casting system ensures superior structural integrity.

For Scalable Medium-Volume Production: With a balance of automation and flexibility, MRK63 suits manufacturers transitioning from small batches to higher volumes without overinvesting in heavy machinery.

For Material Innovation: Supports advanced alloys (e.g., magnesium) for lightweight automotive components or corrosion-resistant industrial parts.

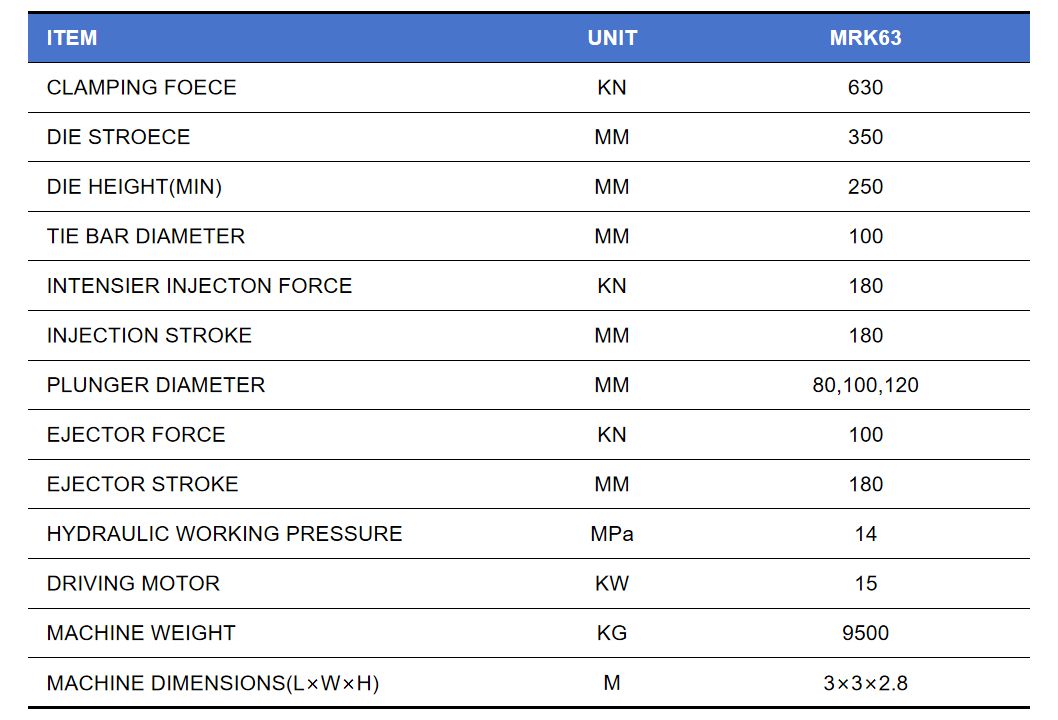

Technical Specifications

The MRK63 vacuum-assisted rotor casting system offers a specialized solution for manufacturers prioritizing precision, material versatility, and medium-scale efficiency. While the MRK40 excels in compact, cost-sensitive production, and MRK100+ targets heavy-industrial applications, the MRK63 stands out for its vacuum technology and adaptability to complex rotor designs.

By transparently outlining each model’s strengths, we empower clients to align their unique production needs with the optimal MRK series solution—ensuring value, quality, and long-term ROI.