LR-ZM5C-120 robotic deburring machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

The LR-ZM5C-120 is a high-performance five-axis intelligent grinding machine designed for high-precision grinding and deburring operations.Equipped with Omron's advanced multi-axis control system and high-performance servo motors,it offers rapid response,precise control,and smooth operation.It is widely used for efficient grinding of complex parts such as die-cast components and machined parts.

The LR - ZM5C - 120 five - axis grinding machine is a high - performance intelligent solution tailored for precision grinding and deburring operations in automated production lines. Equipped with Omron's advanced multi - axis control system and high - performance servo motors, it ensures rapid response, precise control, and smooth operation. This machine is widely applicable for processing die - cast components and other complex parts within automated production lines, delivering unmatched efficiency and accuracy.

Features

1.Five - Axis Coordination

Movement along the X, Y, Z axes and rotation around the B and C axes of this five - axis grinding machine enable multi - directional grinding. The multi - axis control system of the LR - ZM5C - 120 optimizes each movement, ensuring precision in every grind, especially for die - cast components with intricate geometries.

2.Rapid Tool Change

Equipped with a 4 - 6 head rotary tool library, the LR - ZM5C - 120 allows for fast tool changes. This is extremely crucial when handling diverse die - cast components that demand various tools, reducing downtime significantly.

3.Intelligent Operation

The user - friendly system of the LR - ZM5C - 120 five - axis grinding machine can store tens of thousands of programs. During product changeover, one - click retrieval eliminates the need for reprogramming, a boon for die - cast components production where time is of the essence.

4.Robust Structure

The main body of the LR - ZM5C - 120 five - axis grinding machine is crafted from cast iron, offering high rigidity. This design is essential for stable grinding, especially when dealing with heavy and large - sized die - cast components.

5.Flexible Processing

Grinding tools can be easily replaced according to requirements on the multi - axis control system of LR - ZM5C - 120. Whether using flexible or rigid tools, it caters to different materials of die - cast components, from soft alloys to harder metals.

6.Convenient Fixtures

The worktable of the LR - ZM5C - 120 five - axis grinding machine is equipped with quick - change locators for fixtures. This enables rapid fixture replacement, reducing tool - setting and debugging time when switching between different die - cast components.

7.Intelligent Compensation

The tool automatic compensation function of the LR - ZM5C - 120, a key aspect of intelligent compensation, extends tool life. This intelligent compensation is crucial during continuous processing of die - cast components, reducing wear costs significantly. The multi - axis control system works in tandem with this intelligent compensation function to maintain precision. Intelligent compensation ensures that even after prolonged use, the machine’s performance remains top - notch. Another benefit of intelligent compensation is that it adapts to different grinding conditions, optimizing tool usage. Moreover, intelligent compensation helps in maintaining the accuracy of the grinding process over time. Additionally, this intelligent compensation feature minimizes the need for frequent tool replacements, saving both time and resources. Furthermore, intelligent compensation adjusts for any minor tool wear, ensuring consistent results. Also, the intelligent compensation mechanism is designed to work seamlessly with the machine’s overall control system. And, intelligent compensation plays a vital role in enhancing the machine’s efficiency in long - term operations.

8.Flexible Layout

Easy to move, the LR - ZM5C - 120 five - axis grinding machine has a small footprint. This allows for convenient adjustment of the workshop layout and easy integration into automated production lines.

Advantages

1.High Efficiency

The five - axis coordination and rapid tool change of the LR - ZM5C - 120 significantly shorten processing cycles. This is vital for mass production of die - cast components, where high - volume output is required. The multi - axis control system ensures smooth and efficient operation. Integration with automated production lines further boosts efficiency, allowing for continuous production.

2.High Precision

The robust structure and precise control from the multi - axis control system ensure high - quality grinding results. Even for the most intricate die - cast components, the machine delivers consistent precision. Intelligent compensation also plays a role in maintaining this precision over time. Whether used in automated production lines or manual operations, precision is maintained.

3.Intelligent Operation

Program storage and quick retrieval on the LR - ZM5C - 120 five - axis grinding machine reduce operational complexity. Operators can quickly switch between tasks, enhancing overall user - friendliness. This intelligent operation is a valuable asset in both standalone and automated production lines setups.

4.Low Cost

Tool compensation and quick fixture change on the LR - ZM5C - 120 lower tool wear and setup time. The intelligent compensation feature plays a significant role in cost - reduction, making long - term operations more economical. Automated production lines integration also helps in reducing labor costs significantly.

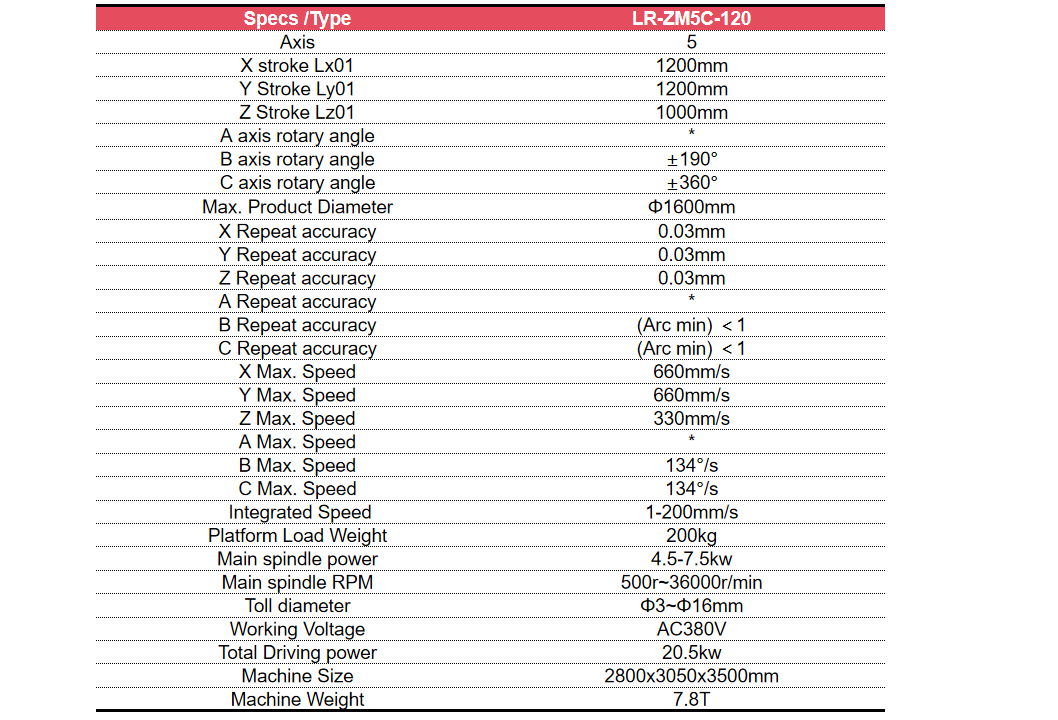

Parameter

The LR-ZM5C-120 five-axis grinding machine leverages advanced multi - axis control system, intelligent compensation, and seamless automation integration to meet the diverse needs of die-cast component processing.