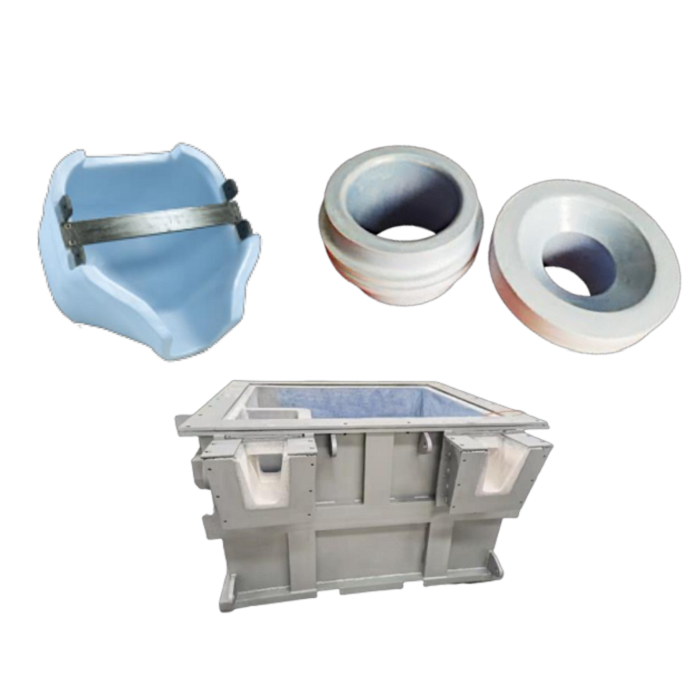

Refractory Solutions:Molten Metal Transfer & Conveying Consumables

Brand :Daseon

Product origin :China

Delivery time :30 Days

A complete range of lightweight, high-insulation, and non-wetting consumables for molten metal transfer. Covering the entire process from ladle to launder, we ensure your molten metal conveying process is efficient, pure, and smooth.

Introduction: Transfer Consumables, the Core Guarantee of the Molten Aluminum "Logistics" Link

In modern precision die casting, the success of Molten metal casting hinges on the critical "logistics process" of transferring molten aluminum. Flaws in this stage—such as heat loss, contamination, or poor flow—can cause costly defects, making professional transfer consumables essential for reducing costs and improving efficiency.

Daseon's "Liners and Components for Molten Metal Transfer & Conveying" series provides a complete set of refractory solutions for aluminum designed to master this key link. Our products cover the entire process, aiming to help customers reduce aluminum melting loss and ensure every drop of molten metal enters the mold in its purest state. Whether using standardized ladles or Custom ceramic fiber shapes, our product line helps eliminate risks at the source, laying a solid foundation for high-quality castings.

Core Product Details: 5 Categories of Consumables Covering the Entire Molten Aluminum Transfer and Conveying Needs

(I) Ceramic Fiber Ladles — The "Lightweight, Insulated Bucket" for Molten Aluminum

Product Overview:A ceramic fiber ladle is the core container for holding and transferring molten aluminum. Compared to traditional cast iron ladles, it leverages the unique advantages of ceramic fiber materials to achieve revolutionary breakthroughs in lightweight design, high insulation, and long service life. It can be used directly without preheating, greatly simplifying the operational process; its excellent insulation performance is the first step in helping customers reduce aluminum melting loss; and its non-wetting property to aluminum significantly reduces the difficulty and time cost of cleaning and maintenance.

Key Features & Value:

——Lightweight and Easy to Handle: Weighing only 1/3 to 1/4 of a cast iron ladle of the same capacity. For example, a 50 kg capacity ceramic fiber ladle can be easily handled by two people without relying on heavy equipment like cranes, greatly enhancing production flexibility and safety, especially suitable for small to medium batch production and manual operation scenarios.

——Excellent Insulation Performance: The thermal conductivity of ceramic fiber is extremely low, which can effectively slow down the temperature drop of molten aluminum. Over a typical transfer distance, the temperature drop is 15-20°C less than that in a cast iron ladle, ensuring that the molten aluminum remains within the optimal process temperature window when it reaches the die-casting machine, avoiding defects such as cold shuts and misruns due to insufficient temperature.

——Completely Non-Wetting to Aluminum, Easy to Clean: The inner wall of the ladle is treated with a special coating that is completely non-wetting to molten aluminum. After each use, only simple cleaning of the dross is required, without the need for strenuous knocking and scraping of the solidified aluminum shell. This not only saves a lot of cleaning time but also avoids damage to the inner wall of the ladle caused by physical cleaning.

——Ultra-Long Service Life: Thanks to its excellent thermal shock resistance and chemical corrosion resistance, the service life of a ceramic fiber ladle can exceed 40,000 cycles under standard use, which is several times that of traditional ladles, significantly reducing the enterprise's consumable procurement costs and replacement frequency.

Applications & Selection:

——Small Batch/Laboratory (0.3~10 kg): Perfectly suited for trial production or small-batch production of samples, electronic accessories, and other small parts, and can be operated directly by hand.

——Medium Batch Production (10~50 kg): Suitable for the production of home appliance accessories, small automotive parts, etc. It can be handled manually or by forklift, achieving the best balance between efficiency and convenience.

——Large Batch Automated Production (50~150 kg): Designed for large factories producing new energy vehicle housings, large structural parts, etc. It can be customized with connection interfaces for robotic arms to achieve 24-hour continuous, efficient unmanned transfer.

(II) Riser Ladle Liners — The "Upgraded Inner Tank" for Traditional Iron Ladles

Product Overview:A riser ladle liner is a cost-effective upgrade solution for enterprises still using traditional cast iron ladles. It is a pre-formed ceramic fiber inner tank that can be directly installed into an old cast iron ladle shell, replacing the original cast iron inner wall, which is prone to rust and aluminum adhesion. This "replace the liner, not the shell" model allows customers to enjoy all the advantages of ceramic fiber materials without having to discard their existing equipment.

Key Features & Value:

——Extremely High Cost-Effectiveness: When the inner wall of an old ladle shows corrosion, cracks, or severe aluminum adhesion, there is no need to spend a lot of money on a brand new ladle. Simply replacing the much less expensive liner is sufficient, typically saving more than 50% of the cost.

——Quick Replacement, Reduced Downtime: The liner is lightweight (usually 5-10 kg), and the replacement process is simple and fast, usually completed within 1 hour without dismantling large equipment, minimizing the impact on production.

——Comprehensive Performance Improvement: After installing the liner, the old ladle immediately gains excellent insulation (temperature drop is 10-15°C less than with a pure iron liner) and non-wetting properties, which not only improves process stability but also extends the service life of the outer iron shell.

(III) Bushings / Adapter Sleeves / Adapter Plates — The "Precision Connectors" for Molten Metal Pipelines

Product Overview:In complex molten metal conveying networks, bushings, adapter sleeves, and adapter plates play the role of "precision connectors," ensuring that the melt can be seamlessly and leak-free connected when transferring between different pipelines and equipment. These seemingly small components are crucial for the smoothness and safety of the entire Molten metal casting process.

Key Features & Value:

——Sealed and Leak-Proof: High dimensional accuracy allows for a tight fit with launders, equipment interfaces, etc., effectively preventing high-temperature molten aluminum from leaking through gaps, thus avoiding safety hazards and material waste.

——Non-Wetting to Aluminum, Ensures Smooth Flow: All contact surfaces are coated with an anti-adhesion layer, ensuring that the melt flows smoothly without solidifying and clogging at the joints, which simplifies maintenance work.

——Highly Customizable: Whether it's a standard bushing for connecting pipes of the same diameter, an adapter sleeve for different diameters, or a one-in-multiple-out adapter plate, we can provide Custom ceramic fiber shapes to perfectly match any of the customer's existing pipeline systems.

(IV) Distribution Plates — The "Smart Flow Divider" for Molten Metal

Product Overview:A distribution plate is a special functional component, mainly installed on a hot top casting table or in a multi-station feeding system. Its core function is to scientifically guide and distribute the molten aluminum, ensuring that it flows evenly and smoothly to each target location.

Key Features & Value:

——Uniform Distribution: The carefully designed flow channel angles and surface treatment can ensure that the flow rate and temperature of the aluminum liquid distributed to each station are basically consistent, thus guaranteeing the consistency of the final products (such as aluminum billets, multi-cavity castings).

——Insulated and Durable: Made of high-quality insulation materials to ensure that the molten aluminum does not cool down locally during the distribution process. Its normal service life can reach 9-12 months, far exceeding that of ordinary materials.

(V) Launders — The "Insulated Highway" for Molten Metal Conveying

Product Overview:A launder is the core channel that connects key equipment such as the melting furnace, holding furnace, and die-casting machine, enabling medium to long-distance transfer of the melt. a high-performance launder must simultaneously possess excellent insulation, thermal shock resistance, and non-wetting properties to aluminum.

Key Features & Value:

——Ultra-Low Heat Loss: Our launders are one of the industry's leading refractory solutions for aluminum. Their superior material and structural design can effectively reduce aluminum melting loss, ensuring that the molten aluminum remains at the ideal process temperature even after long-distance conveying.

——Powerful Thermal Shock Resistance: Capable of withstanding repeated, drastic impacts from high-temperature molten aluminum without cracking, ensuring the continuity and safety of production.

——Ultra-Long Service Life: In the casting industry, the service life can exceed 1 year; in the die-casting industry, it can reach 4-12 months depending on different working conditions, greatly reducing the frequency of maintenance. Our Custom ceramic fiber shapes service can also customize various complex launder components such as elbows and tees for you.

Our Commitment—Efficient, Stable, and Customizable Molten Metal Transfer Solutions

Daseon's five categories of transfer and conveying consumables form a complete set of refractory solutions for aluminum, engineered to solve every logistics pain point in the Molten metal casting process. Our goal is to ensure a "worry-free and smooth" melt transfer that improves production efficiency and reduces costs through superior insulation and anti-contamination. Our rich selection of Foundry consumables for sale provides standard products and customized services for any production scale. Investing in high-quality transfer consumables is a wise choice to guarantee product quality and enhance your factory's competitiveness. If you are looking for reliable Foundry consumables for sale, please contact us.