300 ton Die Casting Machine

Brand :Daseon

Product origin :China

Delivery time :30 Days

Cold Chamber Die Casting Machine RDC300

Spheroidal graphite cast iron mould board, high tensile alloy steel bar, and high-abrasive chromium plating.

Mould control under multi-level pressure and speed, intelligent mould protection against low pressure.

C-shaped or H-shaped crossbeam linked with pillar support to ensure high reliability and precision of material stamping.

Hydraulic gear-type adjusting device.

High-speed ejection and core pulling device.

| Item | Unit | RDC300 | ||

| Die Locking Force | KN | 3000 | ||

| Die Stroke | mm | 460 | ||

| Die Thickness(Min-Max) | mm | 250-660 | ||

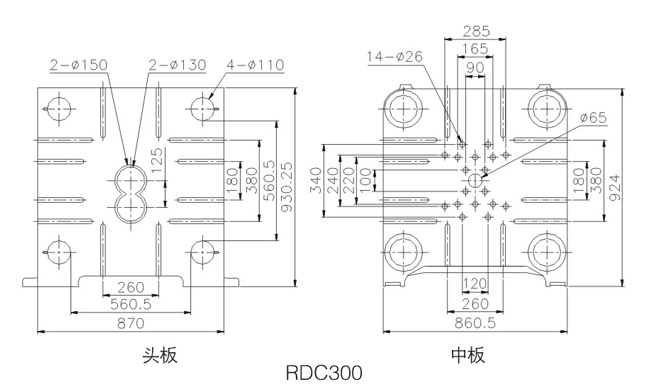

| Die Dimension | mm | 870×930 | ||

| Tie-bar inner Spacing(V×H) | mm | 560×560 | ||

| Tie Bar Diameter | mm | 110 | ||

| Injection Force | KN | 335 | ||

| Plunger Stroke | mm | 440 | ||

| Plunger Tip Diameter | mm | 50 | 60 | 70 |

| Shot Weight(AL) | Kg(AL) | 1.7 | 2.3 | 3.1 |

| Shot Weight(Mg) | Kg(Mg) | — | — | — |

| Specific Pressure | Mpa | 171 | 118 | 87 |

| 40Mpa)Projecting Area | c㎡ | 750 | ||

| Injection Port position | mm | 0,-125 | ||

| Injection Stoke | mm | 180 | ||

| Injection Stroke | mm | 110 | ||

| Over Height of Flange | mm | 12 | ||

| Ejection Force | KN | 150 | ||

| Ejection Length | mm | 105 | ||

| Hydraulic Pressure | Mpa | 14 | ||

| Electric Motor Capacity | KW | 18.5 | ||

| Volume of Oil | L | 600 | ||

| Machine Weight | ton | 11 | ||

| overall dimensions(L×W×H) | m | 6.03×1.4×2.5 | ||

Independent piston-type supercharger

Accumulator with two speed levels ensuring

Fast and stable injection.

High Tensile Clamping System.

a. Spheroidal graphite cast iron mould board and reamer processed by high precision CNC machining center ensure high precision and solidity of mould clamping system.

b. Dual toggle and five pivots ensure the stable and smooth movement of mould board.

c. Wide space between four draw bars and long stroke for mould with large sizes.

d. Adjust mould board by finite-element analysis for the purpose of even stress, low risk of deformation and high-precision of mould clamping.

Ejector adopts special design for adjustable stroke.

Water-cooling oil circuit cooler ensures constant pressure and viscosity of oil.

Hydraulic gear-type adjusting device is easy to use and ensures accurate mould thickness.

Imported clamping force testing device ensures accurate adjustment of clamping force.

Equipped with independent piston-type intensification accumulator,multilevel pressure and speed control in material injection,applicable in the manufacture of a wide range of high-precision die castings.

Hydraulic components from Europe,America and Japan, which ensures no leakage during die casting.

Imported double pump hydraulic system with high and low pressure featuring energy saving and high production efficiency.

Watery-cooling oil circuit cooler ensuring constant pressure and viscosity of oil and stable performance of die casting machine.

Famous-brand programmable controller with touch screen,featuring easy operation and diverse functions,such as trouble shooting,prompt,alarm,production management and data storage.

High-performance injection system:maximum injection speed>=8.5m/s,pressure intensification time<=20ms.

The reamer adopts automatic lubricating system which prolongs the service life of machine and reduces repair frequency.

The double pump hydraulic system with high and low pressure features low noise,energy saving and high production efficiency.

The external filter at the inlet of oil pump ensures clean hydraulic system and protects hydraulic components from abrasion.